Foam liner for electric appliance packaging

A technology of foam and liner, which is applied in the field of structural design of EPS foam liner, can solve the problems of increased transportation and storage costs, irregular and unreasonable structural size, etc., and achieve reduced logistics and transportation costs, compact structure, and economical and reasonable packaging Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

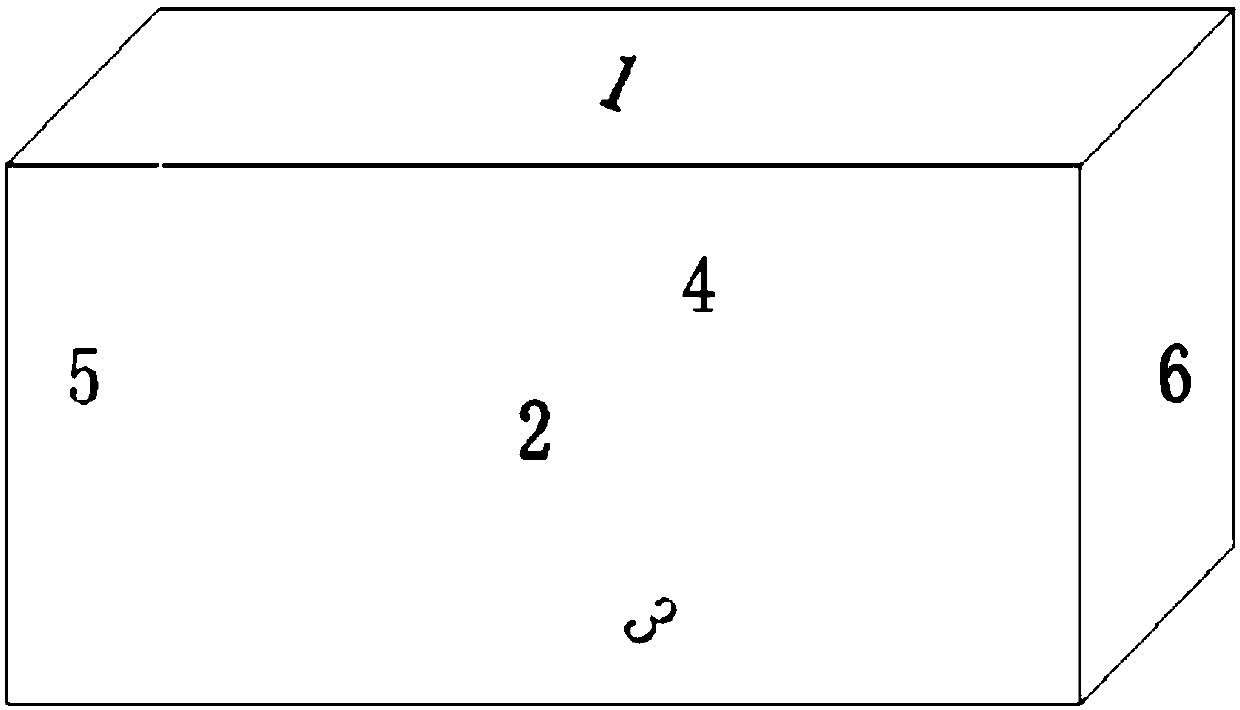

[0026] The present invention will be further described below in conjunction with the accompanying drawings. Divide the falling surface of the TV set with packing box 1—top surface 2—front surface 3—bottom surface 4—back surface 5, 6—two sides;

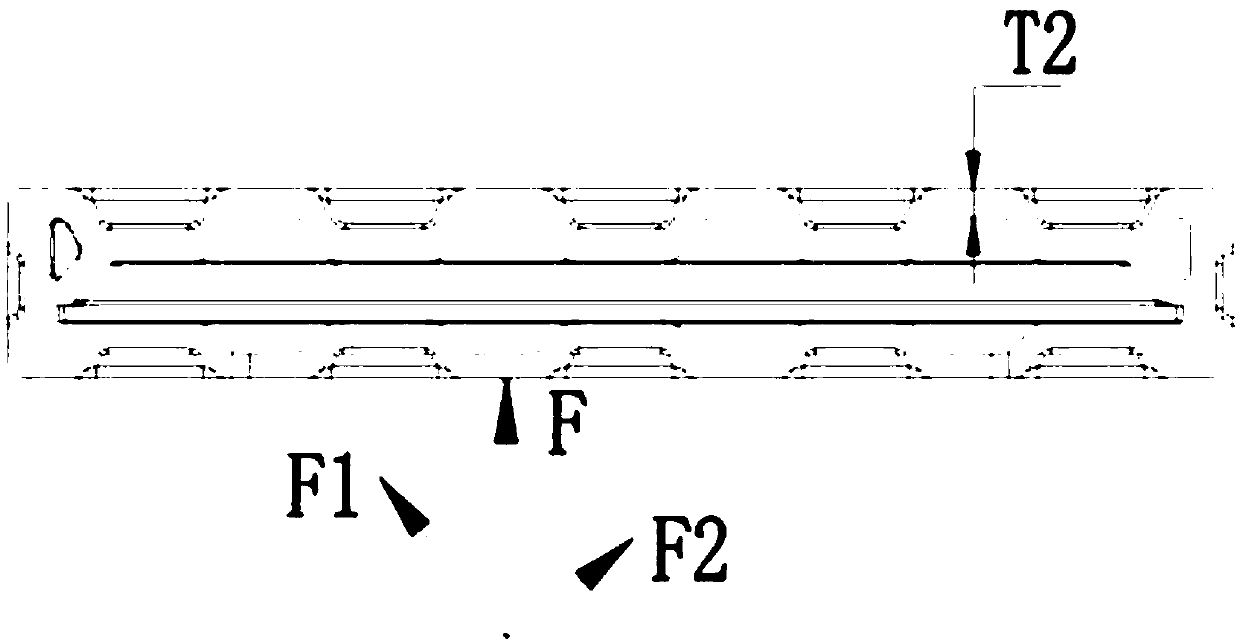

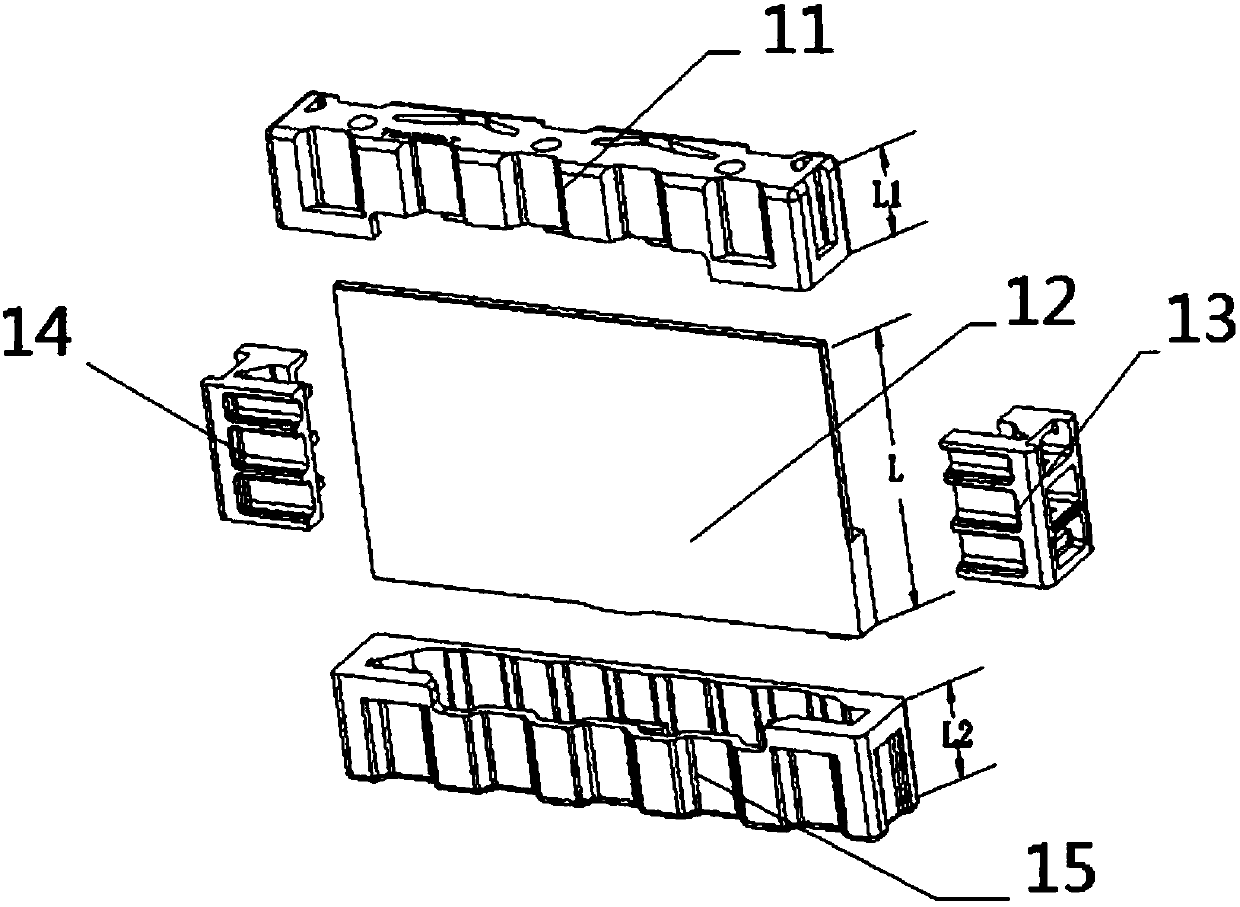

[0027] like figure 1 As shown, it includes an upper foam pad, a lower foam pad, a left foam pad, and a right foam pad; the upper foam pad, the lower foam pad, the left foam pad, and the right foam pad are made of EPS (polystyrene Ethylene) foamed granular material. It is an EPS foam pad suitable for flat-panel TVs with good elasticity, large damping coefficient and strong protection ability.

[0028] According to SJ / T11326-2006 Electronic Industry Standard of the People's Republic of China, that is, the mechanical test requirements in the environmental test method for digital TV receiving and display equipment: for the packaged TV, it is necessary to perform a free drop test on 3 edges, 1 corner and 6 sides.

[0029] Since the drop ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com