Supporting system and supporting method for tender broken roofs of coal roadways

A broken roof and weak technology, which is applied to roof beams supporting mine roofs, earth-moving drilling, mining equipment, etc., can solve the problems of difficulty in maintaining the stability of the roadway, difficulty in forming anchor ends, and short destruction time. The risk of uneven force, the effect of reducing the span and increasing the bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below.

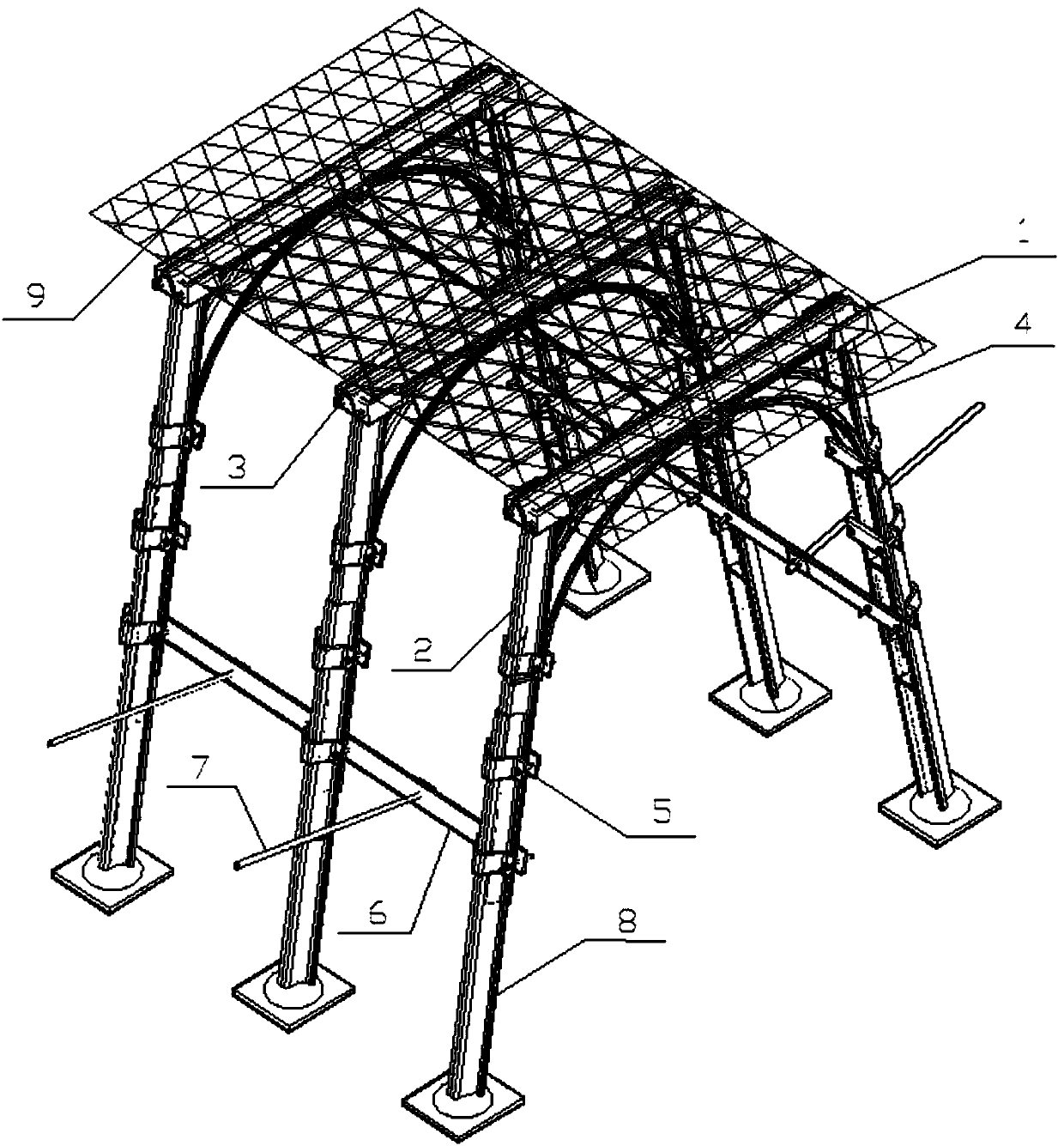

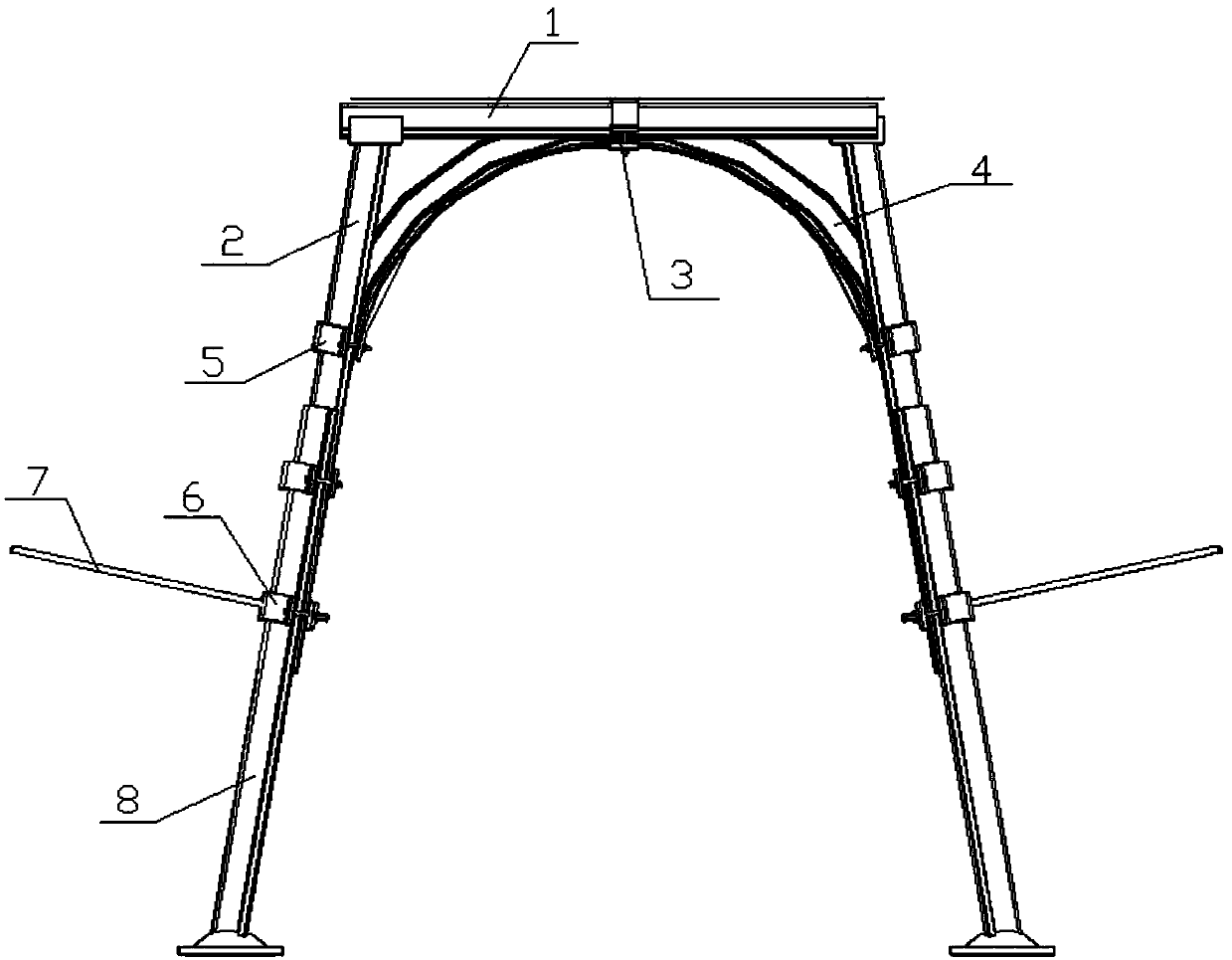

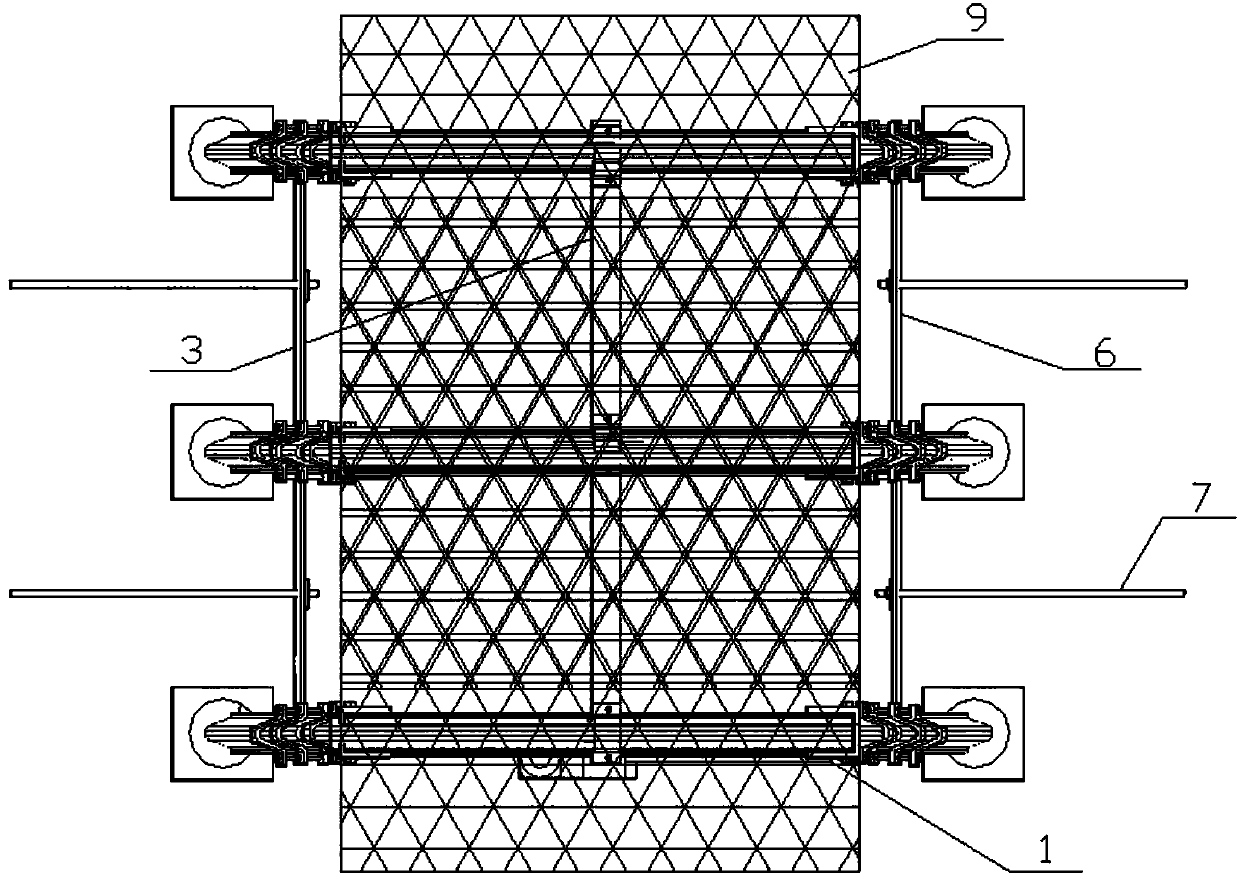

[0039] Such as Figure 1 to Figure 8 As shown, a support system for the weak and broken roof of a coal roadway includes a plurality of support scaffolds and metal support nets 9 arranged parallel to each other. The support scaffolds include two upper shed legs 2 and two lower shed legs. Leg 8, top beam 1 and arched support beam 4, the upper ends of the two upper shed legs 2 are superimposed and fixed with the two ends of the roof beam 1 respectively, and the lower ends of the two upper shed legs 2 are respectively connected with the ends of the two lower shed legs 8 After the upper ends are superimposed, they are fastened and connected by the clamp cable 5. The arched support beam 4 is arranged directly under the top beam 1. The middle part of the arched support beam 4 is superimposed on the middle part of the top beam 1. The two ends of the arched support beam 4 are respectively After superimposed with the two u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com