Accurate butt joint device for hubbed flange and connecting pipe as well as installation and application methods thereof

A docking device and precise technology, applied in flange connection, pipe/pipe joint/fitting, metal processing, etc., can solve the difficulty of maintaining the welding torch vertical and stable welding between the flange and the connecting pipe, and the vertical tolerance of the sealing surface of the connecting pipe and the flange Problems such as over-range and not easy to distinguish and draw quadrants at the docking point can achieve the effects of improving production efficiency and product quality, low cost, and simple structure production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0089] The present invention will be further described in detail through the drawings and examples below. Through these descriptions, the features and advantages of the present invention will become more apparent.

[0090] The word "exemplary" is used exclusively herein to mean "serving as an example, embodiment, or illustration." Any embodiment described herein as "exemplary" is not necessarily to be construed as superior or better than other embodiments. While various aspects of the embodiments are shown in drawings, the drawings are not necessarily drawn to scale unless specifically indicated.

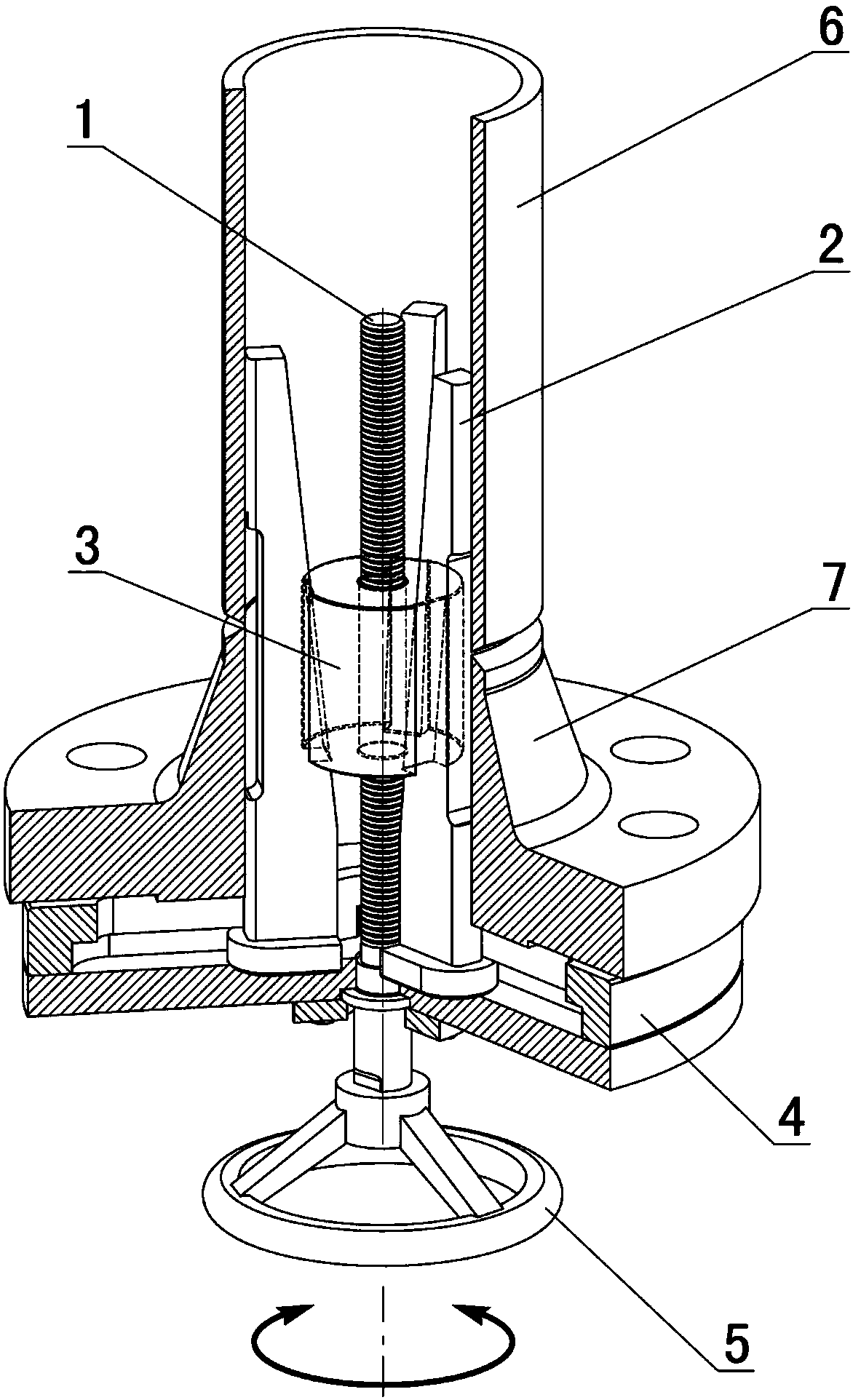

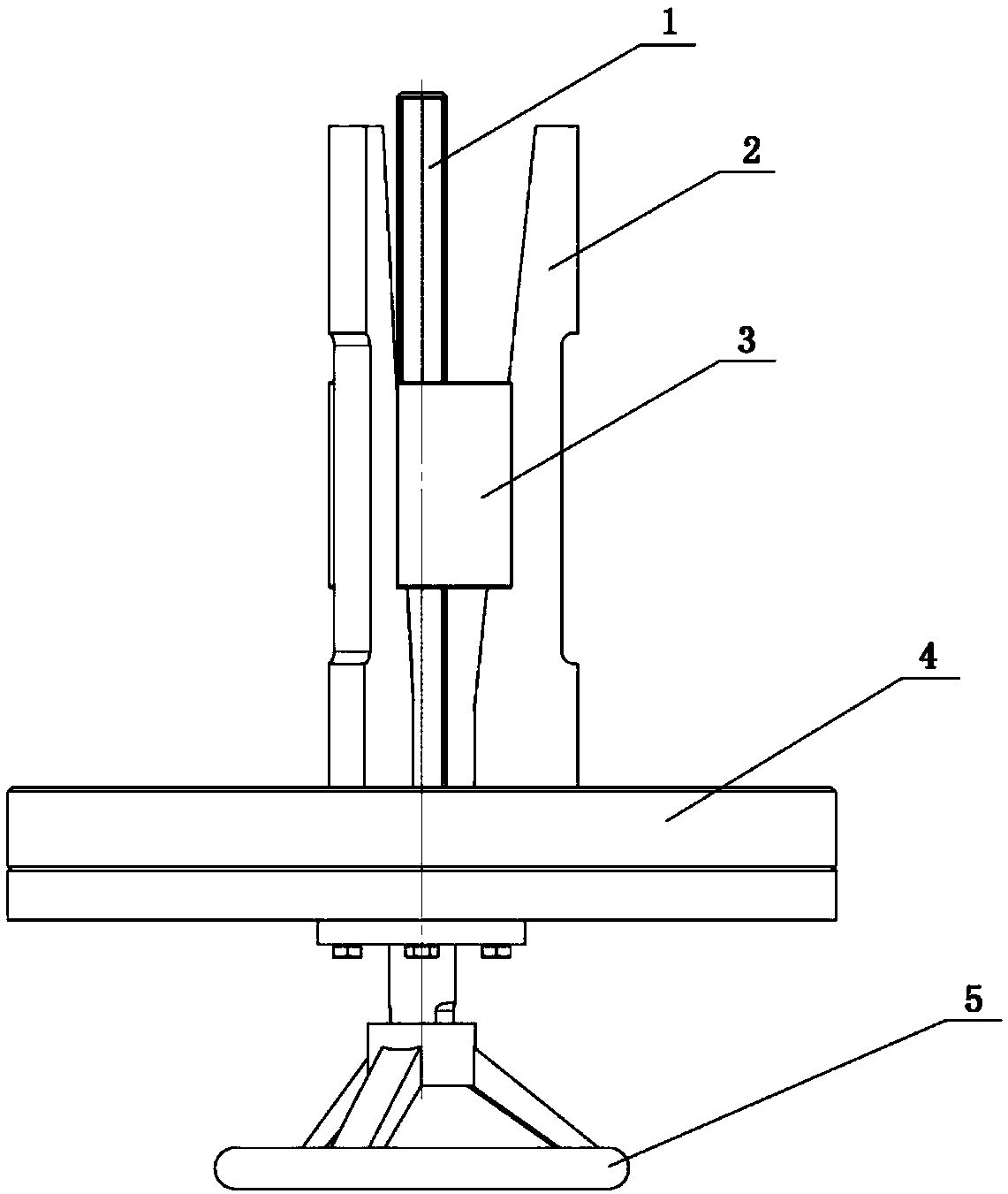

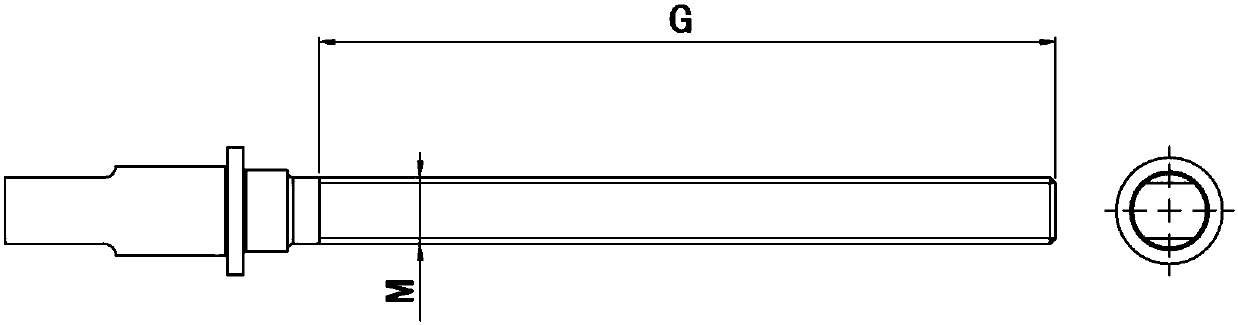

[0091] According to the present invention, there is provided a precise docking device between a flange with a diameter and a connecting pipe, refer to figure 1 with figure 2 As shown, the precision docking device includes a lead screw 1, a cone plate 2, a pressure sleeve 3 and a chuck 4, and the screw 1 passes through the pressure sleeve 3 and the chuck 4 and is connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com