A pressure-applying fixture for a stripline temperature coefficient tester and its use method

A temperature coefficient and tester technology, applied in the application of thermometers, thermometers, thermometer parts, etc., can solve the problems of high and low temperature boxes with large volumes and unguaranteed test accuracy, and achieve small heat transfer and accurate pressure tests , to avoid the effect of high and low temperature impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

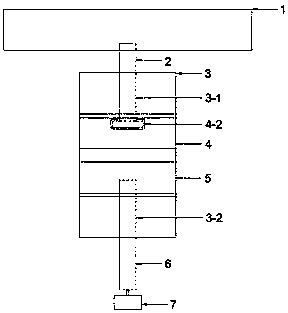

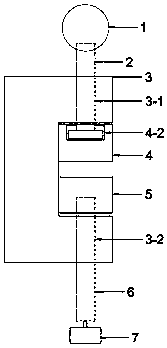

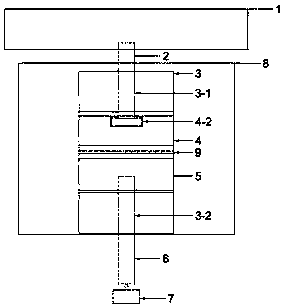

[0009] Such as figure 1 , 2 , 3, a strip line temperature coefficient tester with a pressure fixture, including the force rod 1, the force rod connector 2, bow frame 3, upper slider 4, sliding hole 4-2, lower slider 5. The sensor connector 6 and the pressure sensor 7, the upper end surface of the bow frame 3 has a threaded hole 3-1 that matches the force rod connector 2, and the lower end surface has a through hole 3-2, and the threaded hole 3-1, the through hole 3-2 On a central line, the force rod connector 2 is bolt-shaped, screwed on the threaded hole 3-1 of the bow frame 3, one end is fixed on the force rod 1, and the other end of the bolt head is placed on the upper slide In the sliding hole 4-2 in the block 4, the force applying rod connector 2 can slide and rotate, and the sensor connector 6 is a cylinder with threads at one end and an outer arc surface at the bottom of the other end, which runs through the through hole of the bow frame 3 3-2 into a sliding fit, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com