Liquid crystal dimming film and liquid crystal dimming laminated glass

A technology of liquid crystal dimming film and sheet glass, applied in windshield, optics, nonlinear optics, etc., can solve problems such as time-consuming, failure of liquid crystal dimming film, complicated electrode manufacturing process, etc., to improve production efficiency and finished products efficiency, reduce film removal process, and solve unusable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

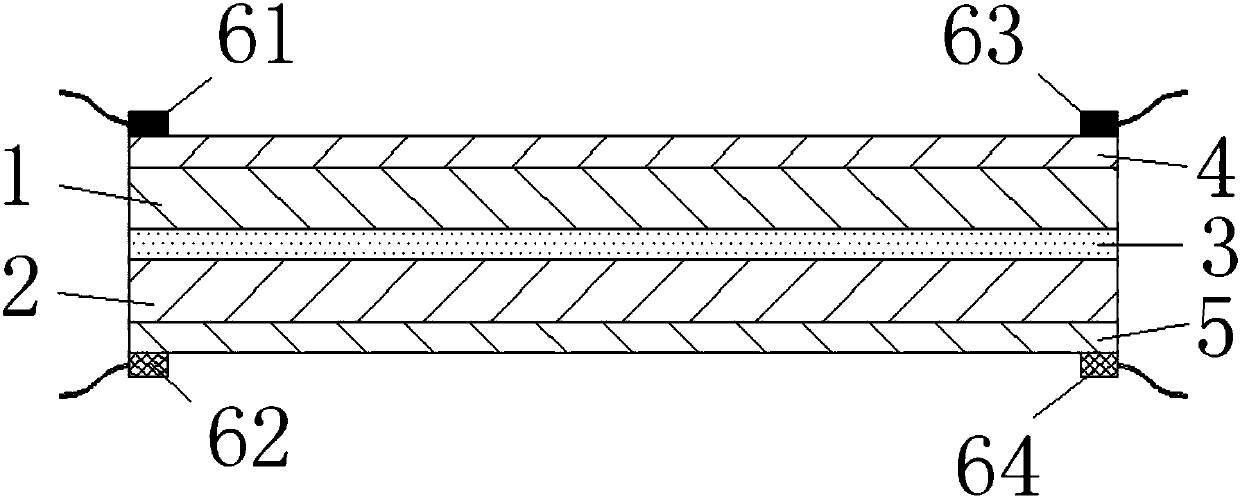

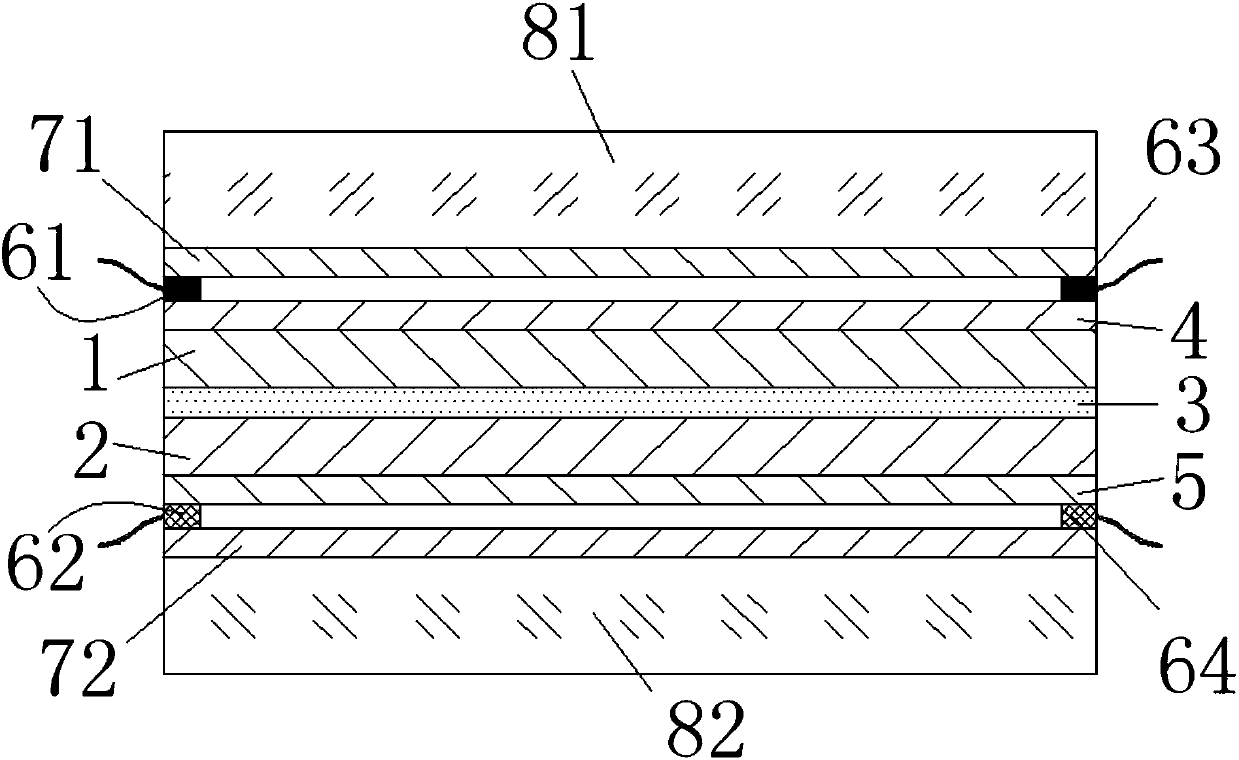

[0022] The content of the present invention will be further described below in conjunction with the accompanying drawings.

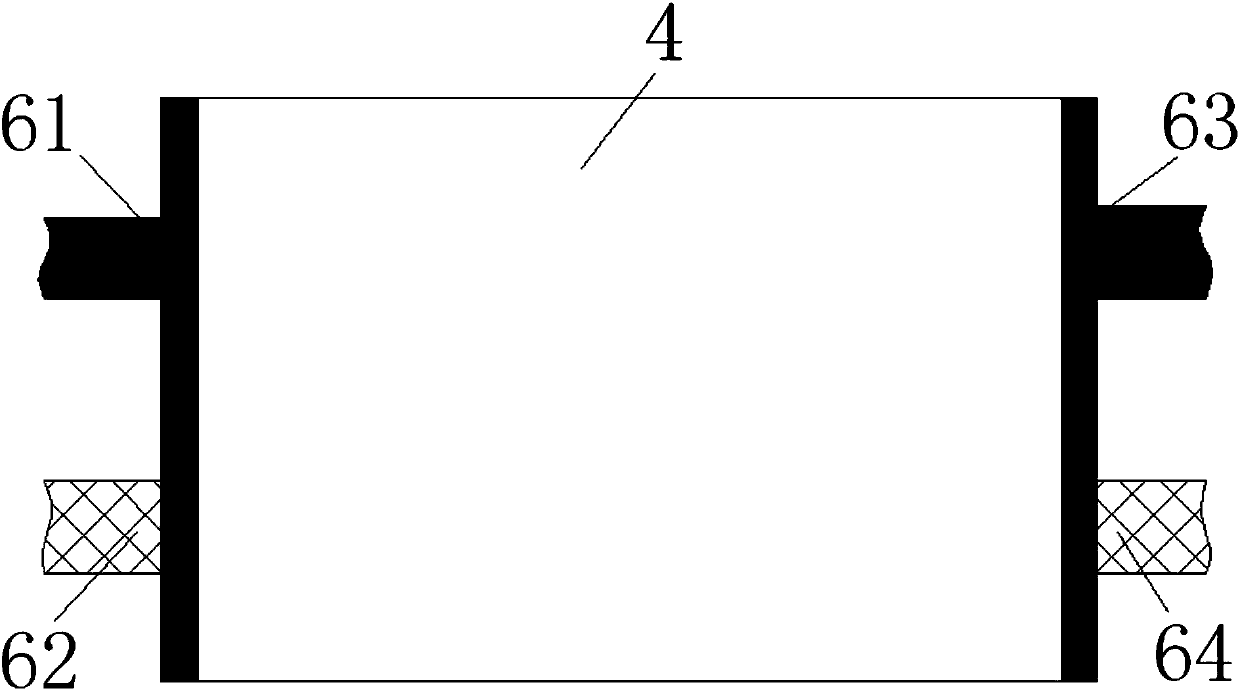

[0023] Such as Figure 1~2 As shown, a liquid crystal dimming film according to the present invention includes a first transparent substrate 1, a second transparent substrate 2, and a polymer dispersed liquid crystal sandwiched between the first transparent substrate 1 and the second transparent substrate 2 Layer 3, characterized in that: the first transparent conductive layer 4 is provided on the side of the first transparent substrate 1 facing away from the polymer dispersed liquid crystal layer 3, and the side of the second transparent substrate 2 facing away from the polymer One side of the dispersed liquid crystal layer 3 is provided with a second transparent conductive layer 5, a first electrode 61 is provided at a first edge of the first transparent conductive layer 4, and a second electrode 61 is provided at a second edge of the second transparen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com