Slot wedge processing device adapt to different widths

A technology that adapts to different processing devices. It is applied in the use/manufacture of slot locking devices, electromechanical devices, and manufacturing of motor generators. It can solve the problems of not being able to meet the forming and processing of slot wedges of different widths, troublesome processing, and low production efficiency. , to achieve the effect of improving the timeliness of waste removal, preventing the generation of sparks, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

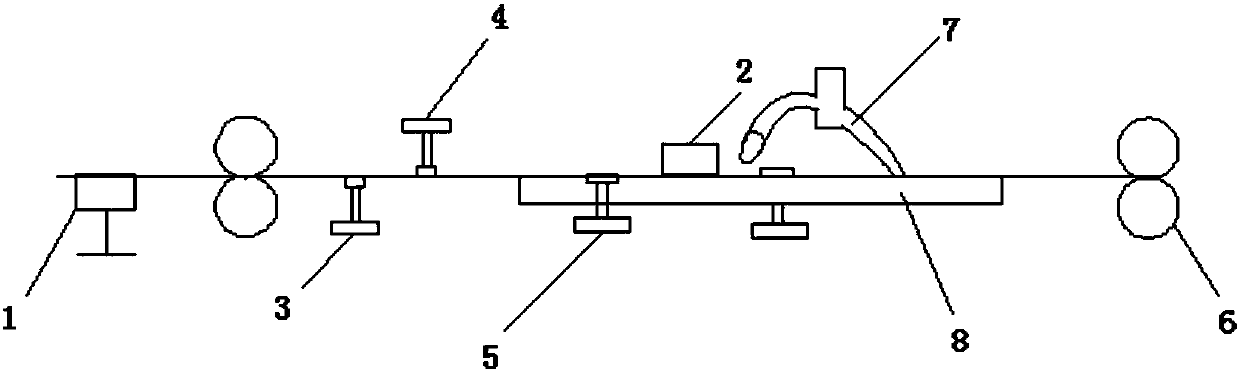

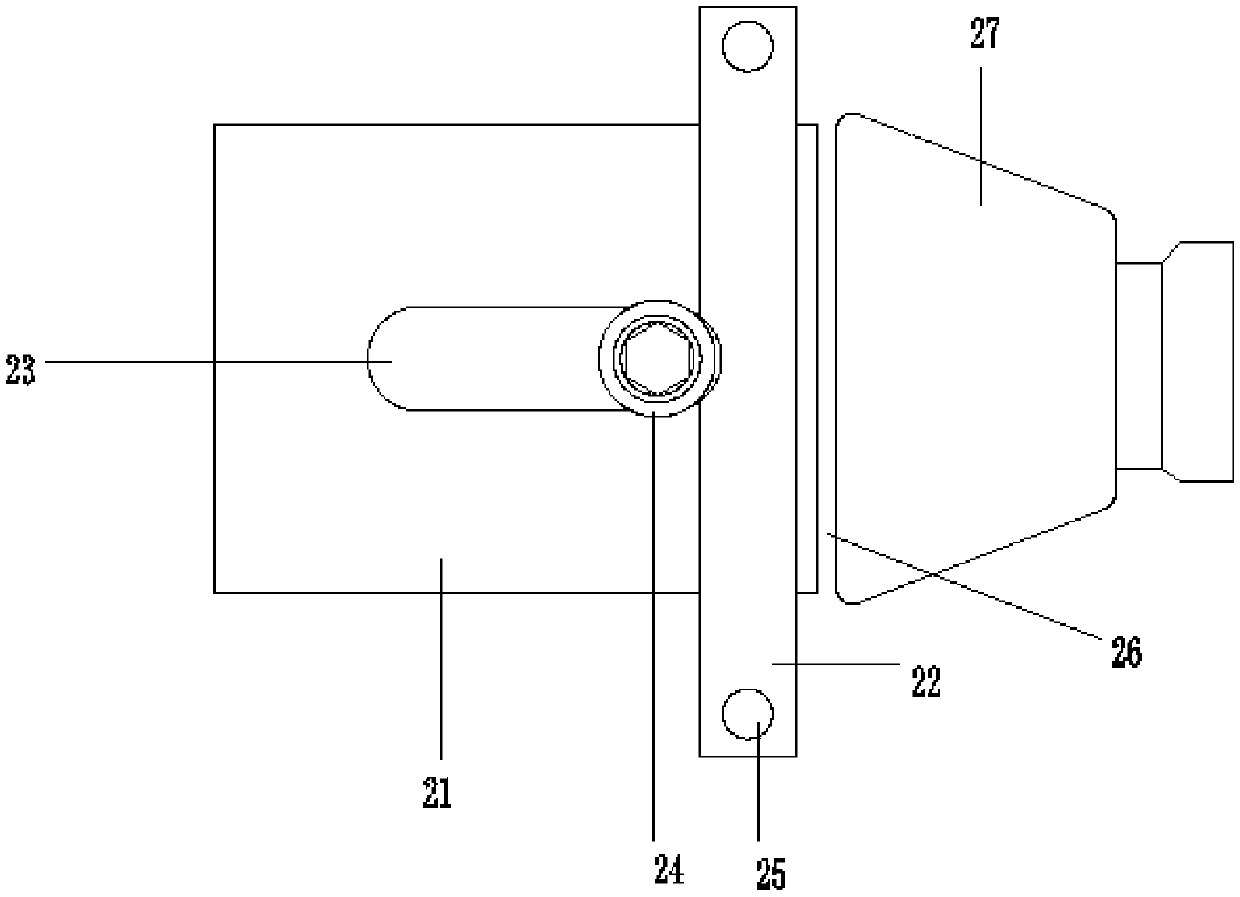

[0019] Such as figure 1 , figure 2 and image 3 As shown, a slot wedge processing device adaptable to different widths in this embodiment includes: a clamping device 1 , a polishing device, a milling device, a conveying device and a width adjusting device 2 .

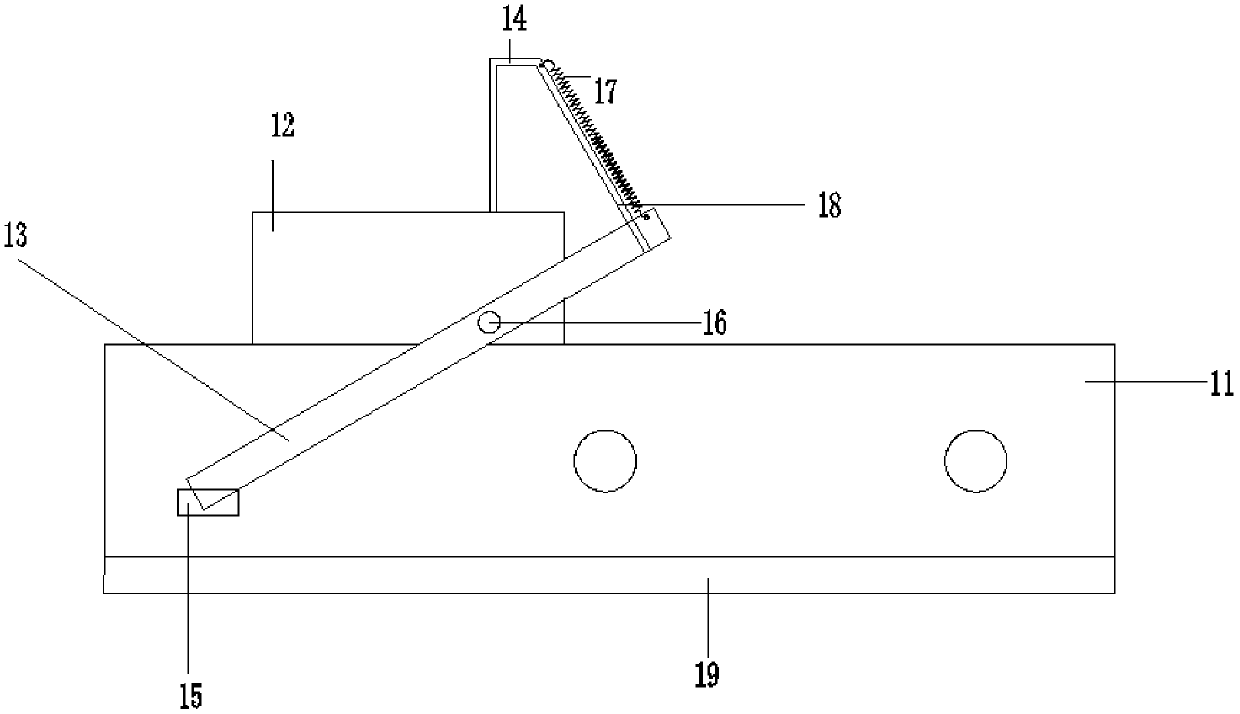

[0020] The clamping device 1 includes: a positioning platform 11, a positioning plate 12, a connecting rod 14 and an adjusting device. The adjusting device is L-shaped, including an adjusting plate 13 and an elastic device. The front end of the adjusting plate 13 is provided with a pressing block 15. A screw 16 is provided, the screw 16 is fixed on the positioning plate 12, one end of the elastic device is fixed on the adjustment plate 13, and the other end is fixed on the connecting rod 14, and the elastic device is guaranteed to be in a stretched state.

[0021] The polishing device includes a first milling cutter 3 and a second milling cutter 4; the first milling cutter 3 is arranged on one side of the entrance ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com