Force sensor for surgical device to prevent ingress of fluids

A force sensor and reservoir technology, applied in the field of force sensors of electric surgical devices, can solve problems such as damage to the sensing element, damage to the integrity of the protective coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

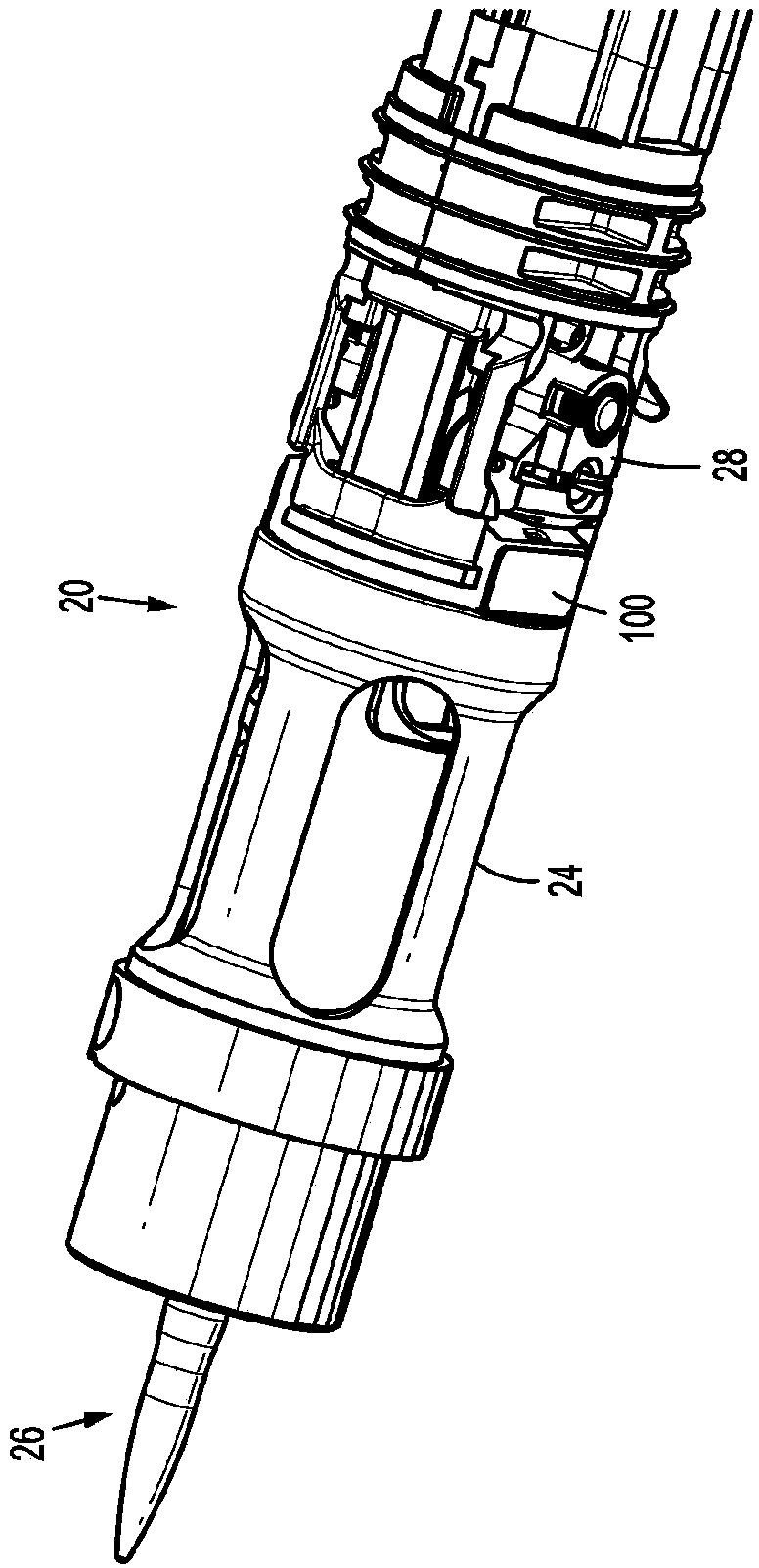

[0036] The force sensors of the present disclosure include sensing elements such as surgical devices that are protected from harsh environments such as automatic irrigation and / or autoclaving. A force sensor consists of a substrate having mounted thereon a sensing element, such as a strain gauge and its supporting electronics, covered by a seal and / or plate to form a leak-proof barrier to protect the sensing element. element.

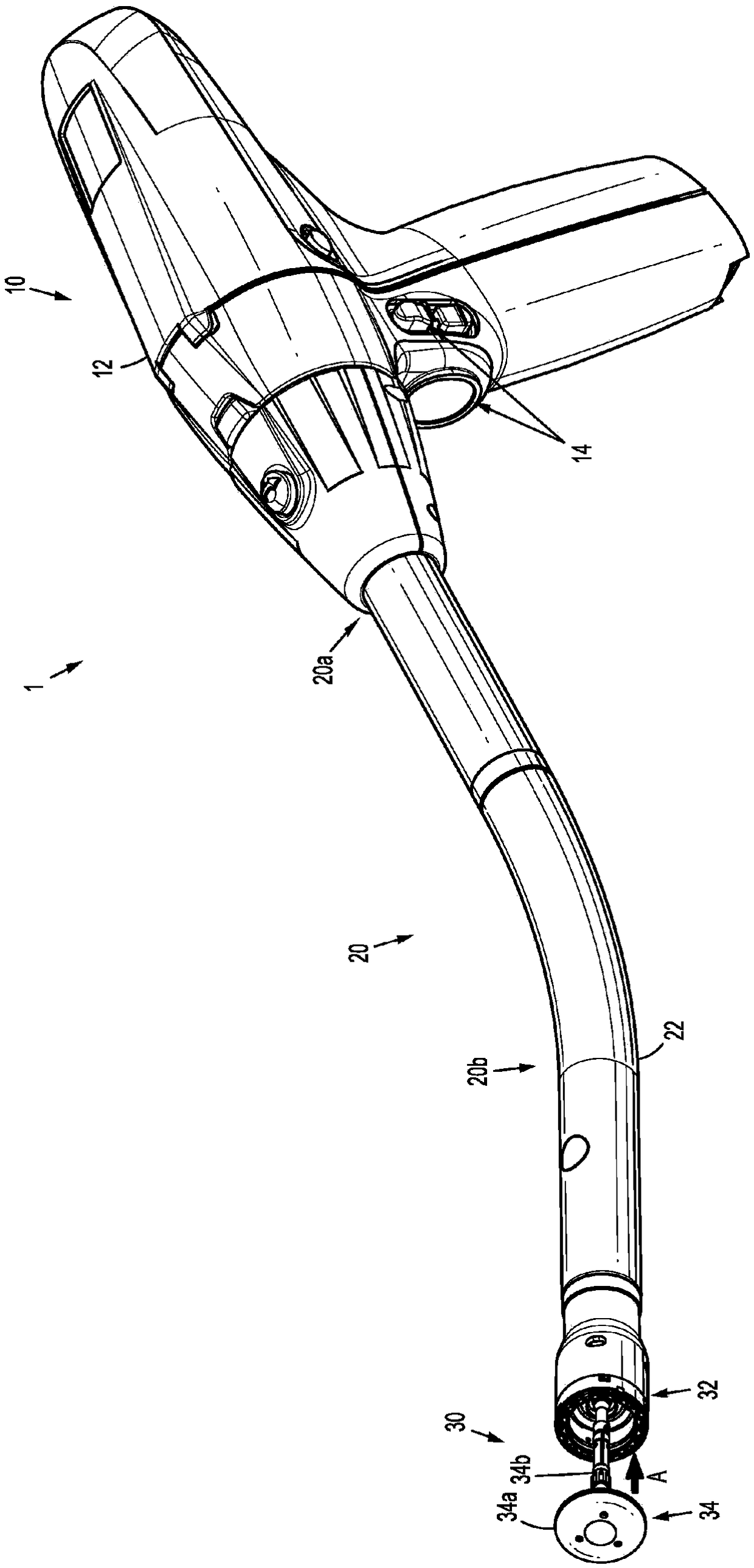

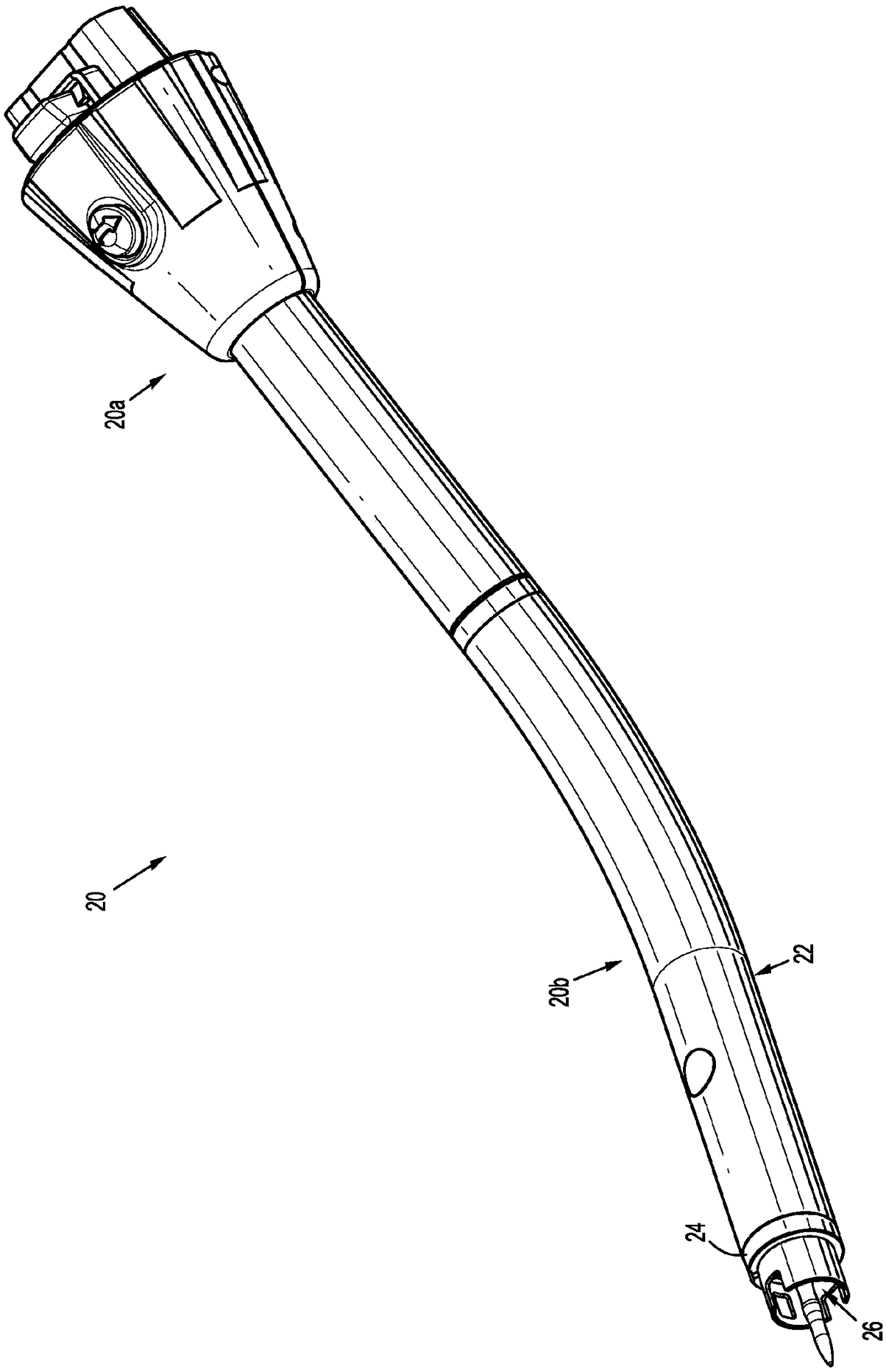

[0037] Embodiments of the present disclosure are now described in detail with reference to the drawings, wherein like reference numerals designate like or corresponding elements in each of the several views. Throughout this specification, the term "proximal" refers to the portion of the device or components thereof that is closer to the user's hand, and the term "distal" refers to the portion of the device or components thereof that is further from the user's hand. Directional reference terms such as "top", "bottom", "upper", "lower" and the like are i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com