Seeded nanoparticles, their preparation and use

一种纳米棒、纳米结构的技术,应用在纳米颗粒领域,能够解决有限等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0107] Example 1 - CdSe / Cd x Zn 1-x S nanorods

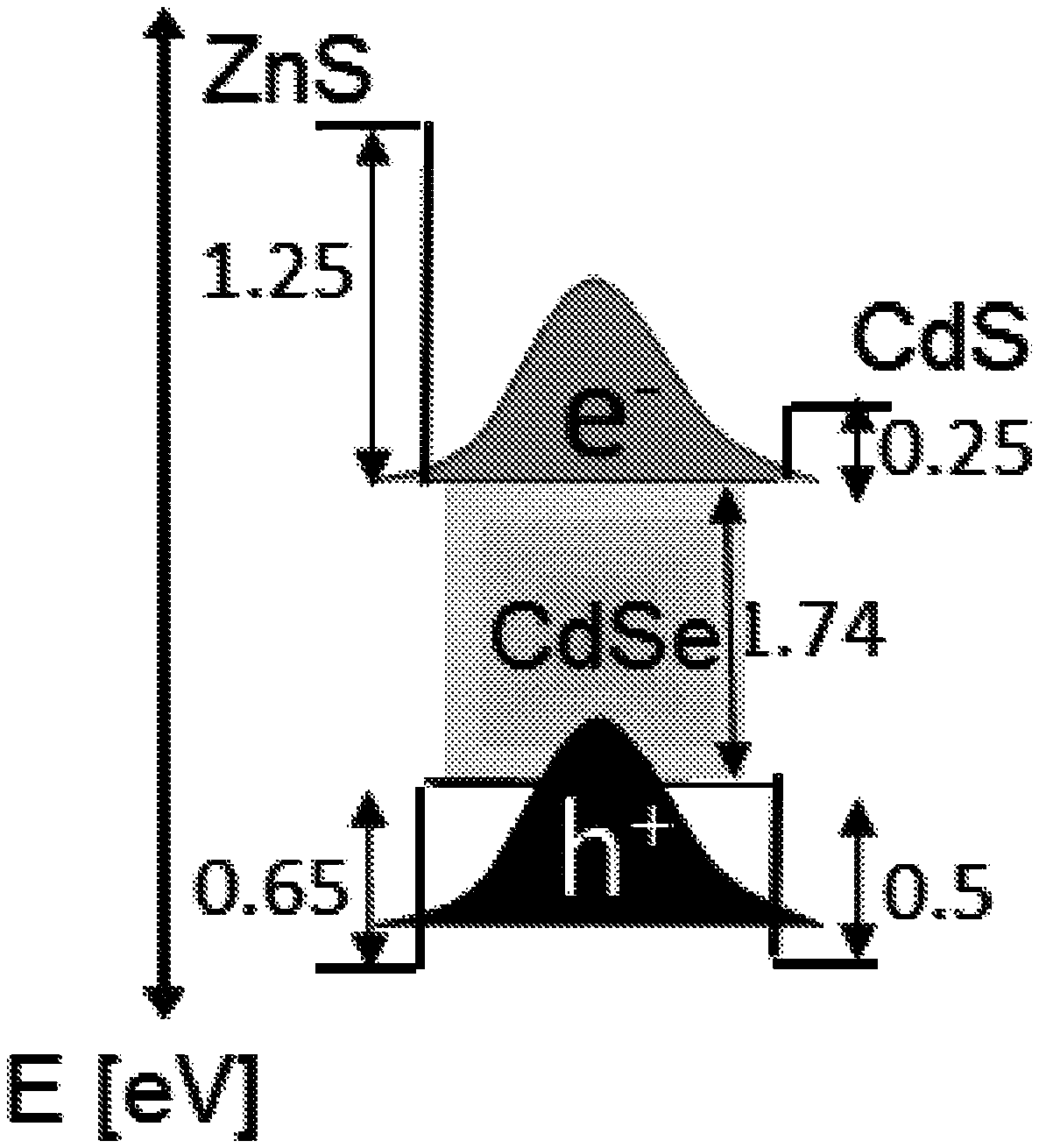

[0108] CdSe seeds and S-precursor (S-TOP) were injected into the flask containing Cd precursor, phosphonic acid and TOP / TOPO. In the initial stage of growth, the reactive Zn precursor was slowly added to the synthesis. exist figure 1 The relative band alignments of CdSe, ZnS, and CdS semiconductors depicted in , demonstrating a more pronounced type I configuration in CdSe / ZnS compared to CdSe / CdS nanorods. Considering the lattice mismatch between these materials, it is expected that in CdSe / Cd x Zn 1-x There is an increased quantum yield in the S nanorod structure. The structure is obtained via an initial reaction of the seed with a suitable precursor of CdS, followed by (and in some cases simultaneously with) a slow rate addition of the zinc precursor to form the alloy shell, using suitable synthetic additives and temperature control.

Embodiment 1A

[0109] Example 1A - CdSe / Cd with small seeds (2nm) x Zn 1-x S nanorods

[0110] 6.1x10 in a 2.5:1 ratio with CdO -4 Molar amounts of CdO, hexylphosphonic acid (HPA) and octadecylphosphonic acid (ODPA) were added to a three-neck flask containing trioctylphosphine oxide (TOPO) and evacuated at 150°C. The flask was heated to 300°C under an argon atmosphere. Subsequently, trioctylphosphine (TOP) was added to the flask. Afterwards, the temperature in the flask was raised to 380° C., where a solution of small CdSe seeds (about 2 nm) in sulfur-TOP was rapidly injected into the flask. 6 ml of zinc oleate was added to the flask during the first 10 minutes of the synthesis. The reaction was stopped after 1 hour, cooled to room temperature and its contents were stored under argon atmosphere.

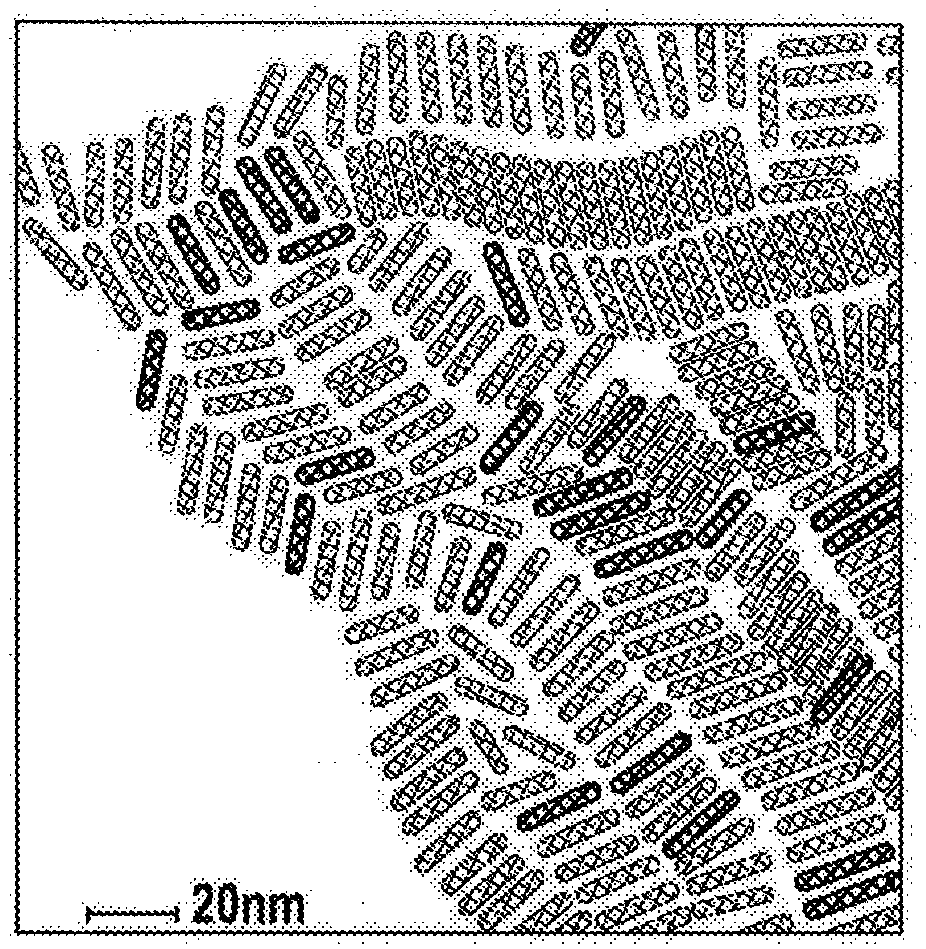

[0111] In this synthesis, small CdSe seeds - approximately 2nm - were implanted, resulting in green-emitting NRs. When compared with NR synthesized without Zn addition ( Figure 2A ), the r...

Embodiment 1B

[0129] Example 1B - CdSe / Cd with large seeds (3.5nm) x Zn 1-x S nanorods

[0130] 1.9x10 in a 4:1 ratio with CdO -3 Molar amounts of CdO, hexylphosphonic acid (HPA) and octadecylphosphonic acid (ODPA) were added to a three-necked flask containing trioctylphosphine oxide (TOPO) and evacuated at 150°C for 1.5 hours. The flask was heated to 300°C under an argon atmosphere and maintained at this temperature until the solution was clear. Subsequently, trioctylphosphine (TOP) was added dropwise into the flask. After that, the temperature in the flask was raised to 360°C, where a solution of CdSe cores in sulfur-TOP was rapidly injected into the flask. 20 ml of zinc oleate was added to the flask during the first 10 minutes of the synthesis. The reaction was stopped after 1 hour, cooled to room temperature and its contents were stored under argon atmosphere.

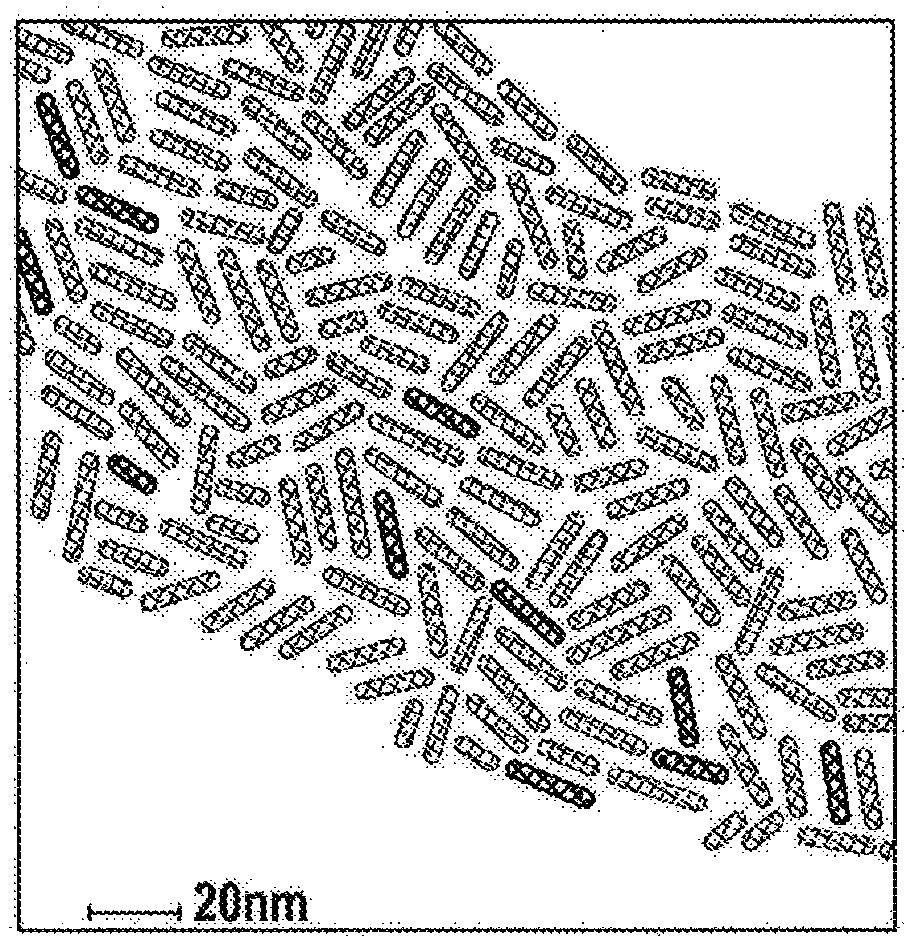

[0131] This example is similar to Example 1A, but larger CdSe seeds, approximately 3.5 nm in diameter, were injected int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com