Microwave chained turn-around machine

A rotary machine and chain technology, which is applied in the direction of special dry distillation, biofuels, products, etc., can solve the problems of insufficient pyrolysis, waste, and scattered biomass pellets, so as to achieve uniform material spreading, prevent material splashing, The effect of improving airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

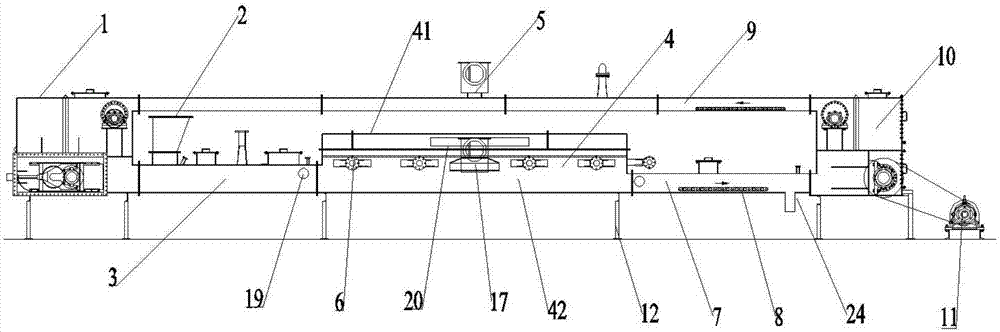

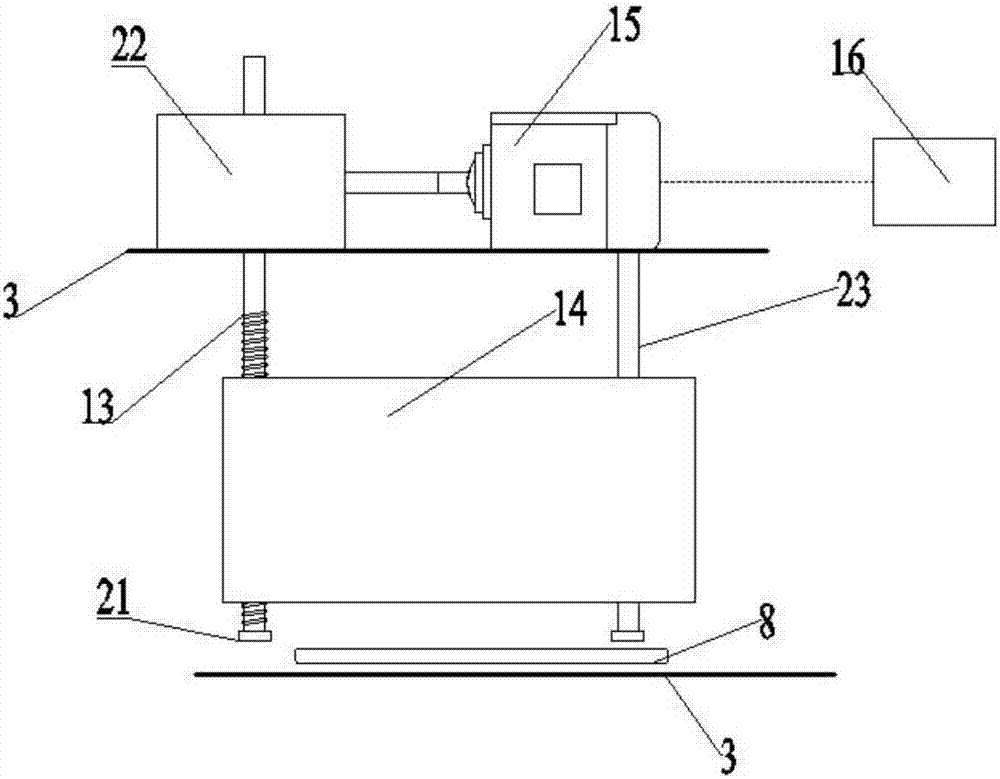

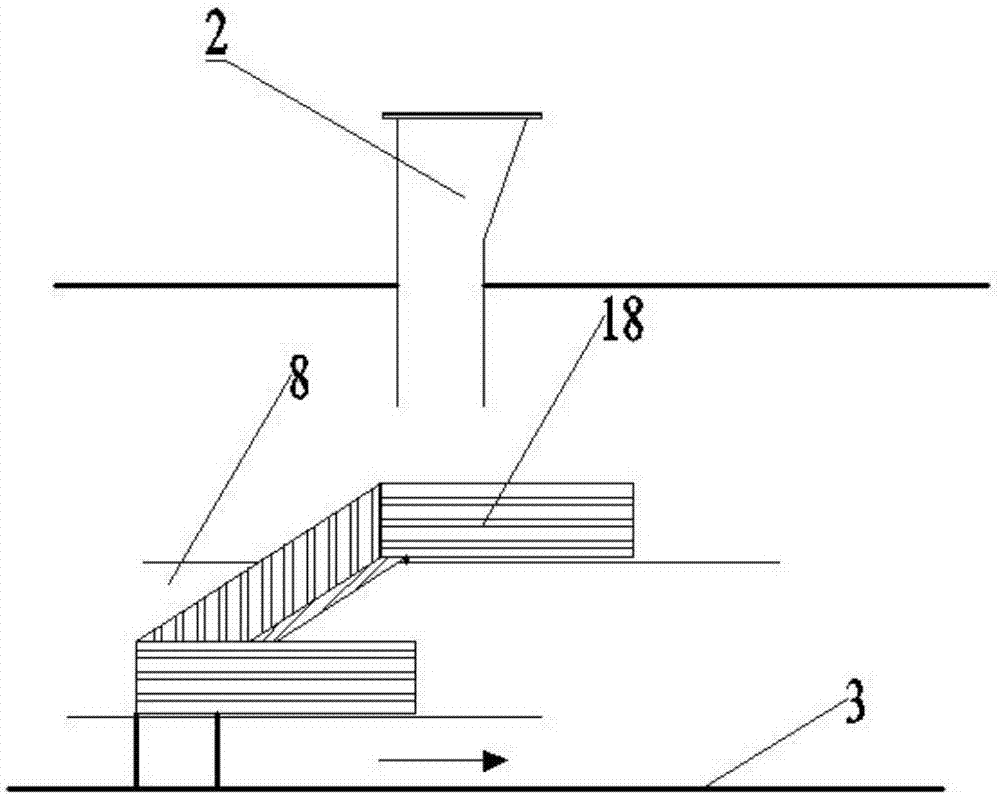

[0019] The concrete content of the present invention is described in detail below in conjunction with accompanying drawing and embodiment: figure 1 As shown, the present invention provides a microwave chain rotary machine, including a body, a frame 12, a driving device 11 and a scraper chain 8, and the body is mainly composed of a tail part 1, a feed suppression section 3, a pyrolysis chamber 4, and a discharge chamber. The suppression section 7, the head section 10 and the return section 9 are sequentially connected to form a rotary closed box, wherein the tail section 1 and the head section 10 are located at both ends of the body, and the return section 9 is located at the feed suppression section 3, pyrolysis chamber 4 and The top of the discharge suppression section 7; the frame 12 is located at the lower end of the body to support the body; the feed suppression section 3 is provided with a feed port 2; the pyrolysis chamber 4 includes an upper casing 41 and a lower cavity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com