Forming tool and method for annular composite part with section in pi shape

A technology of forming tooling and forming method, which is applied in the field of forming tooling of π-shaped cross-section annular composite parts, which can solve problems such as glue accumulation, part deformation, and part precision tolerance, and achieve the effect of ensuring inspection accuracy and improving inspection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below.

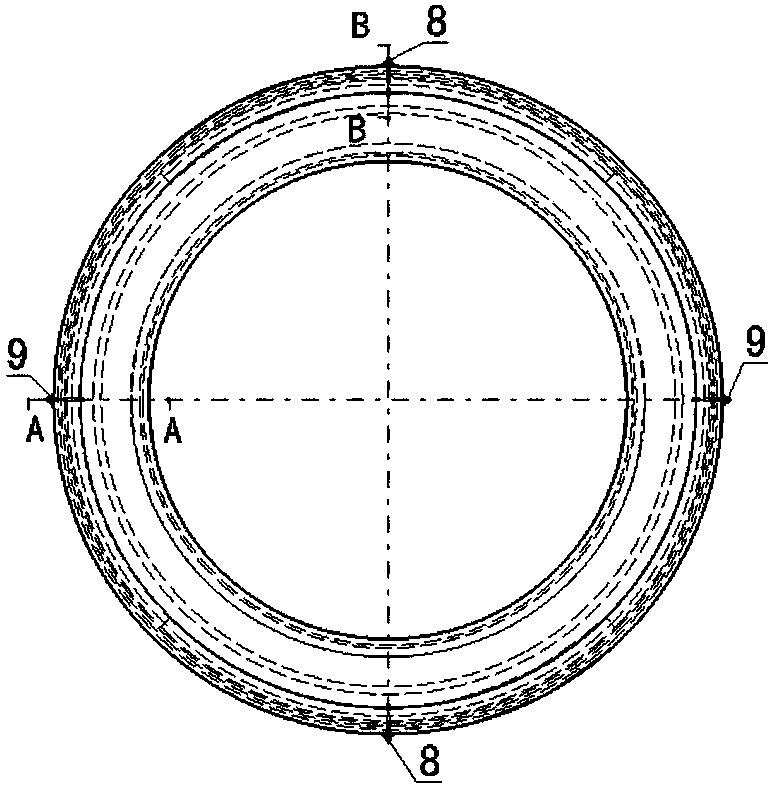

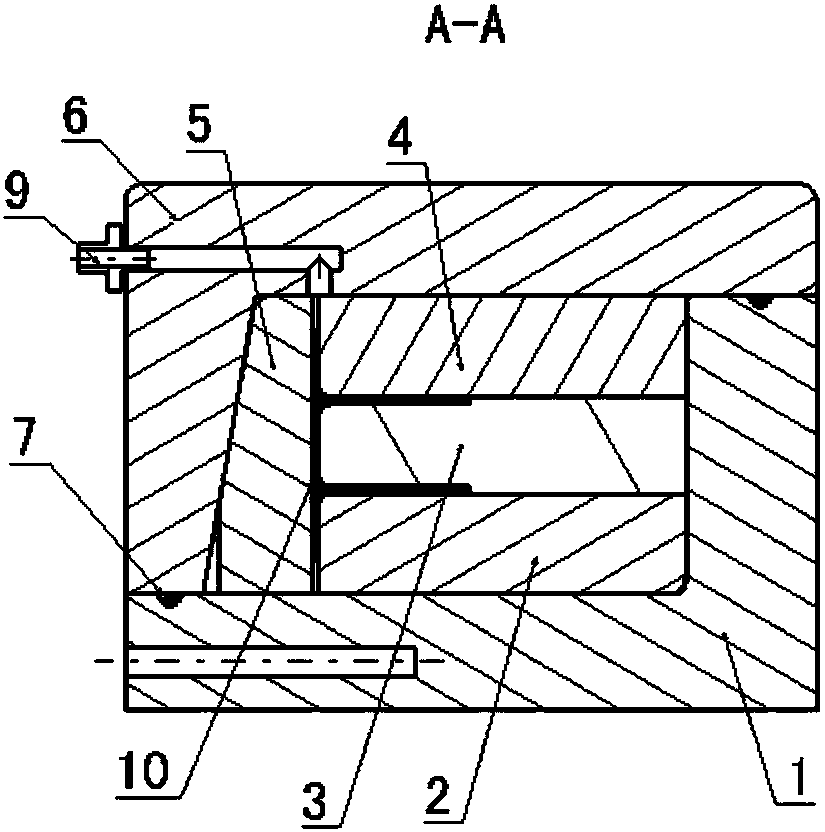

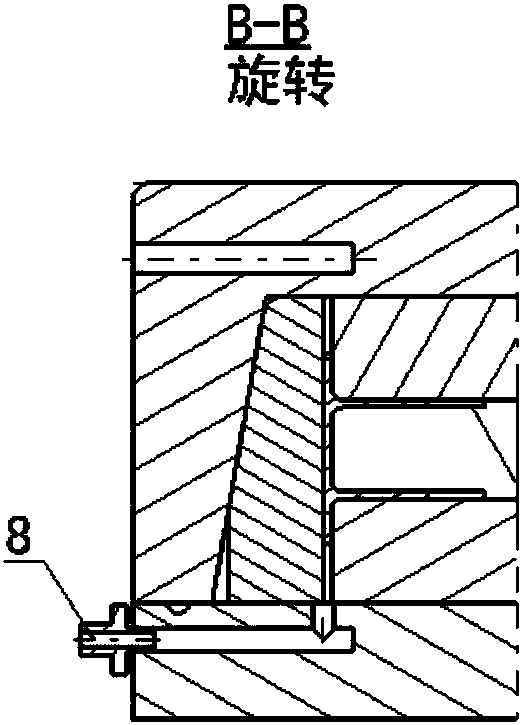

[0031] A molding tool for π-shaped cross-section annular composite parts, the molding tool includes an outer base 1 and a cover plate 6, and an inner lower module 2, middle module 3, upper module 4 and outer module 5, wherein the outer The module 5 is a segmented annular structure, and the other parts are an integral annular structure. The combination of the internal modules forms an annular π-shaped cavity; the butt joint surface of the base 1 and the cover plate 6 is equipped with a rubber strip 7 , and extrude the internal modules through the inner surface of the cavity formed after the butt joint, a glue injection nozzle 8 is provided on the base 1 circumference, a vacuum nozzle 9 is provided on the cover plate 6 circumference, and respectively pass through The corresponding pipeline communicates with the π-shaped cavity.

[0032] The cross section of the base 1 and the cover plate 6 is “L” shape, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com