AR image plate alignment machine

An image pairing and plate machine technology, applied in plate preparation, printing and other directions, can solve the problems of high work intensity, requiring staff to lean over the workbench, and expensive plotters, so as to reduce work intensity and production. Costs, effectiveness in improving productivity and quality of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

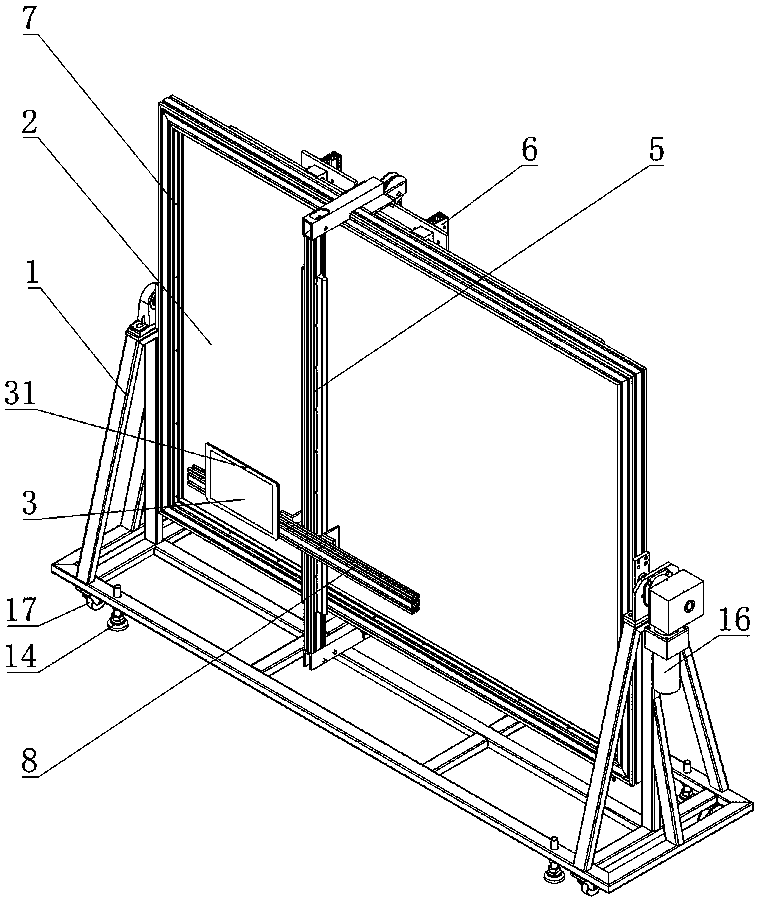

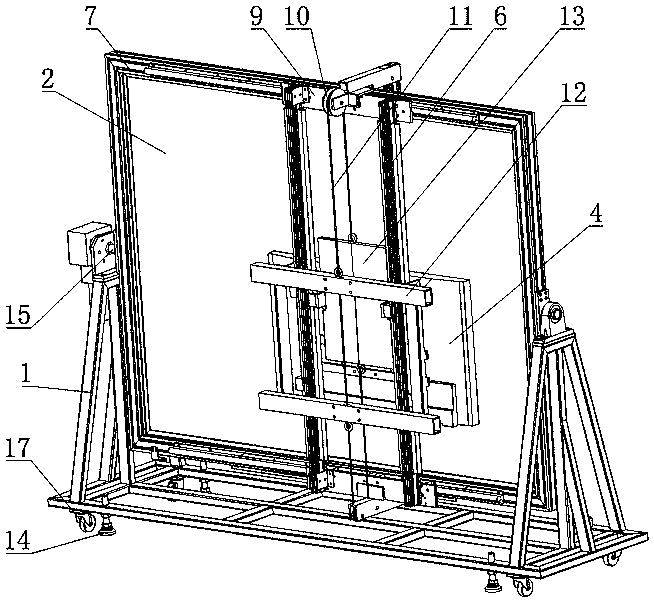

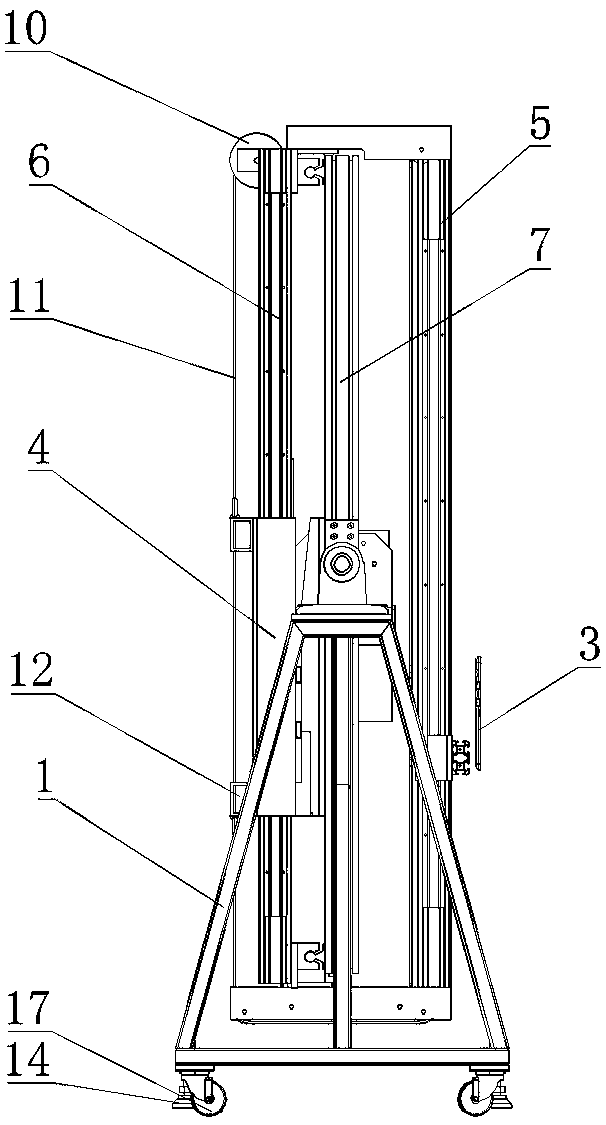

[0017] As shown in the figure, the AR image registering machine, the so-called AR image registering machine, refers to the light intensity virtual reality image registering machine, which has a frame 1, and a reversible flip frame 7 is installed on the frame 1, so A transparent plate 2 is installed in the flipping frame 7, a movable tablet computer 3 is arranged on one opposite surface of the transparent plate 2, and a movable display screen 4 is arranged on the other opposite surface, wherein the tablet computer 3 has Aim at the camera 31 of the display screen 4, and there are patterns to be aligned, and the patterns in the tablet computer 3 can be displayed on the display screen 4. The tablet computer 3 has a camera 31, and the camera has a cross alignment center for alignment Pre-paste the rubber sheet. The tablet computer 3 and the display screen 4 are respectively parallel to the transparent plate 2, and can move separately or synchronously. The synchronous movement can r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com