Internal-combustion engine

An internal combustion engine and fuel technology, applied in mechanical equipment, engine components, engine control, etc., can solve problems such as reducing the adhesion of deposits, and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 Embodiment approach

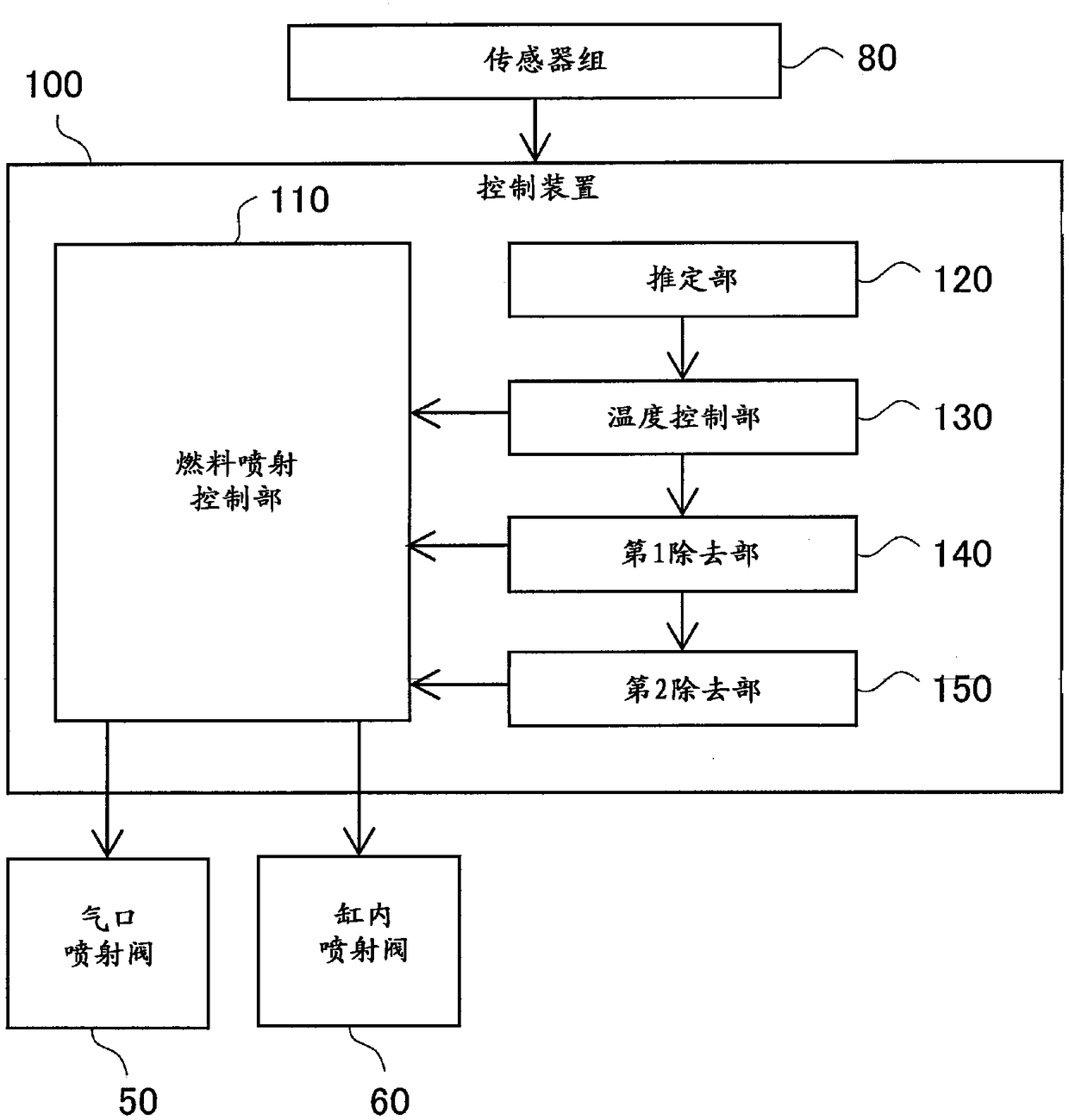

[0148] In the second embodiment of the present invention, the sediment estimation process (step S120 ) is different from that of the first embodiment. Other than that, it is the same as that of the first embodiment. Duplicate descriptions are appropriately omitted.

[0149] In the sediment estimation process of the second embodiment, the control device 100 (estimation unit 120) monitors Figure 6 Feedback corrections as shown are substituted for the count Z. When the feedback correction amount exceeds the allowable value Dth (in Figure 6 In the example shown, it is time ta), and the control device 100 estimates that thermoplastic deposits have been formed in the nozzle holes 61 .

[0150] Furthermore, not only thermoplastic deposits but also thermoset deposits lead to an increase in the amount of feedback correction. This means that it can be said that the estimation accuracy of the second embodiment is lower than that of the first embodiment. However, even if the estima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com