Pre-hinge splitting spacer

A two-split and spacer technology, which is applied to the installation of devices for maintaining the distance between parallel conductors, electrical components, and cables, can solve the problems of wire wear and reduce the service life of two-split spacers, and achieves extended service life and simple structure , the effect of reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

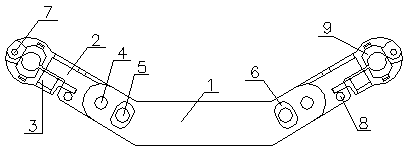

[0013] A pre-hinged two-split spacer, comprising a V-shaped frame 1, two wire clamp arms 2 and two wire clamp pressure plates 3, the middle parts of the two wire clamp arms 2 passing through the shaft 4 and the V-shaped frame 1 respectively. The two arms are rotatably connected, the ends of the two wire clamp arms 2 are provided with stoppers 5, the two arms of the V-shaped frame 1 are provided with limit slots 6 for placing the stoppers 5, and the The upper end is connected with the end of the wire clamp arm 2 through the pin shaft 7, and the other end of the wire clamp pressure plate 3 is clamped by the locking rod 8 installed on the wire clamp arm 2. Damping pads 9 are respectively installed in the semi-circular arc.

[0014] As a further improvement of the above technical solution, the damping pad 9 is a synthetic rubber pad.

[0015] As a further improvement of the above technical solution, the V-shaped frame 1 is a glass fiber reinforced plastic insulating frame.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com