Supply device and supply method for particulate matter in sealed ablation reaction chamber

A technology of particulate matter and reaction chamber, applied in feeding devices, gas generating devices, chemical instruments and methods, etc., can solve the problems of bulkiness, inability to remove molten solidified lumps well, and containers not suitable for space applications, etc. , to avoid overheating problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings, but this is only exemplary and not intended to limit the protection scope of the present invention.

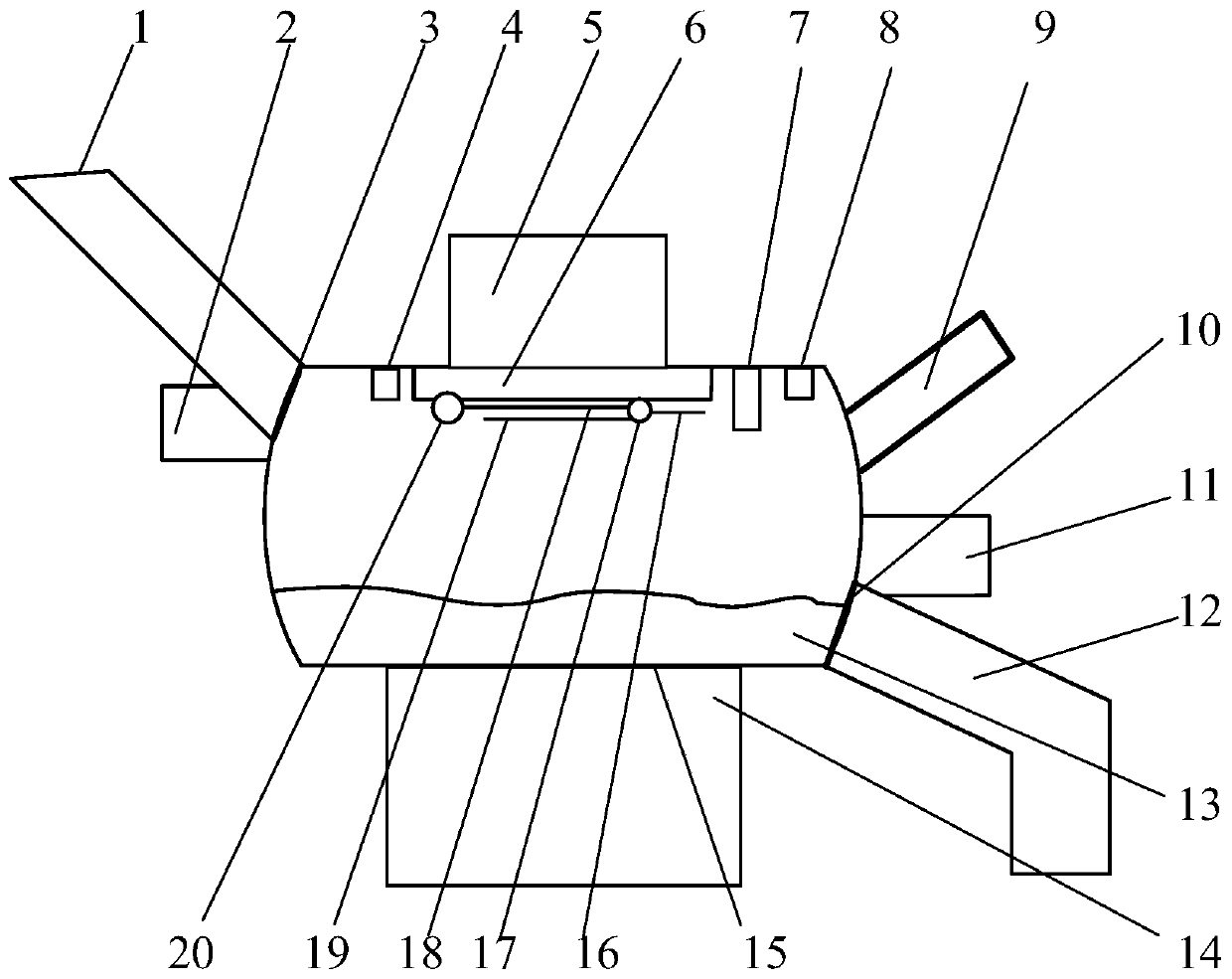

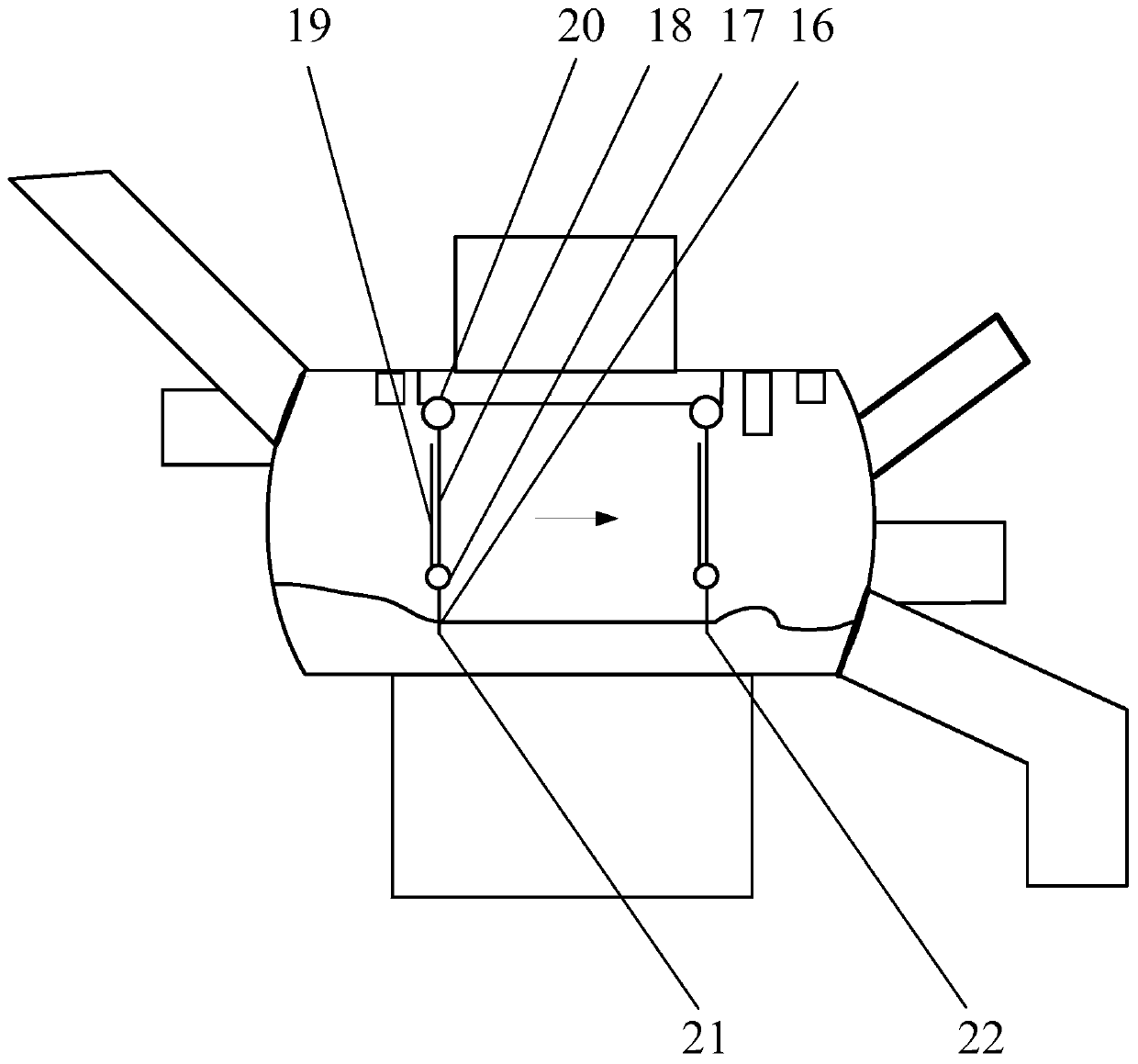

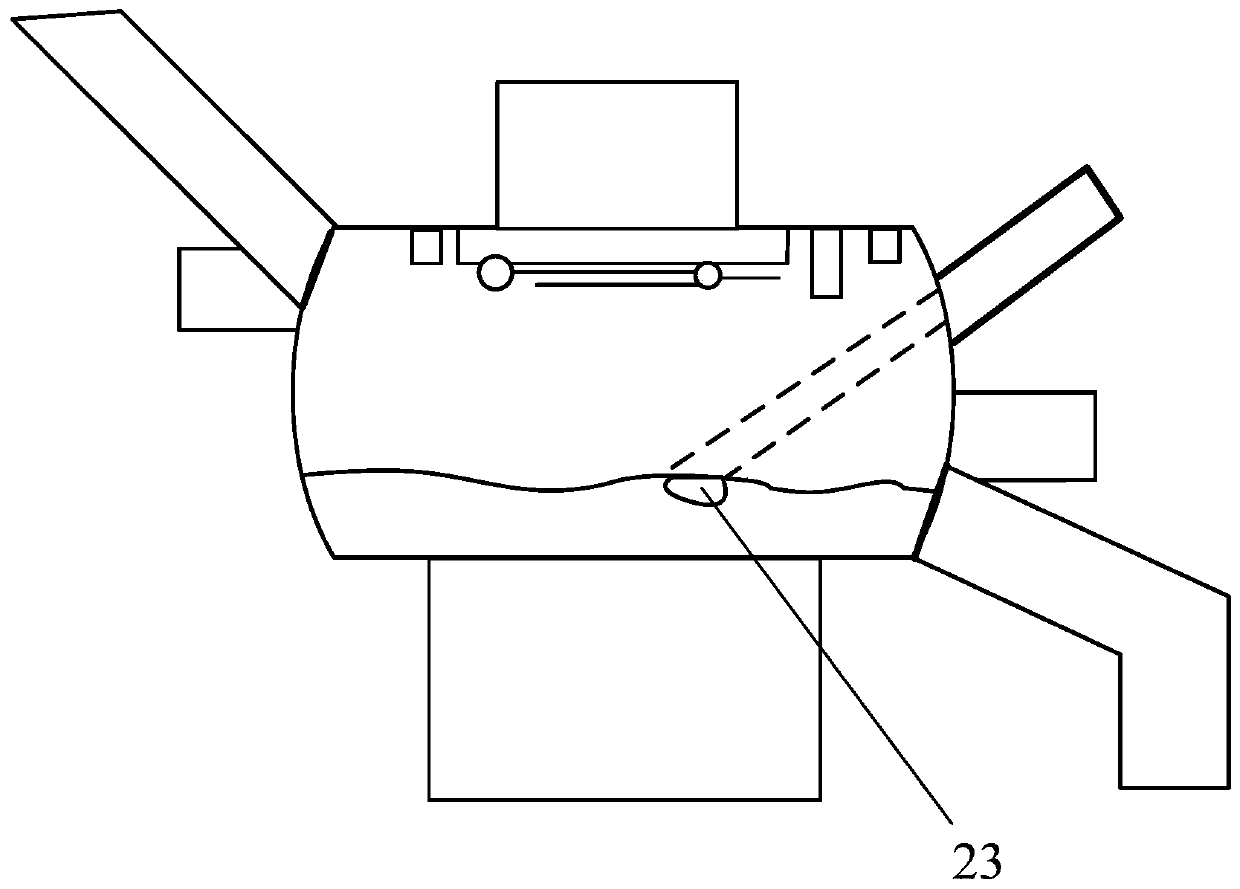

[0032] see Figure 1a-Figure 1d It shows the replenishment device for particulate matter in the sealed ablation reaction chamber, the replenishment device includes a reaction chamber 15, a particle outlet channel 12, a particle inlet channel 1, an air inlet 4, an air outlet 8, a moving mechanism bracket 6, and a monitoring device 7 , the radiating light component 9 and the reaction chamber support 14 for supporting the reaction chamber, the upper part of one side of the reaction chamber 15 is provided with a particle inlet channel 1, and the lower part of the other side of the reaction chamber 15 is provided with a particle outlet channel 12, and the particle inlet channel 1 and The inlet valve 3 and the outlet valve 10 driven by the driving mechanism are respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com