Painting device for mainframe box plates

A painting device and main box technology, which is applied in the direction of spraying device, spray booth, etc., can solve the problems of poor painting effect, easy flow of paint, uneven paint on the surface of main box board, etc., so as to improve processing efficiency and reduce labor Operation, guarantee the effect of painting processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below by means of specific embodiments:

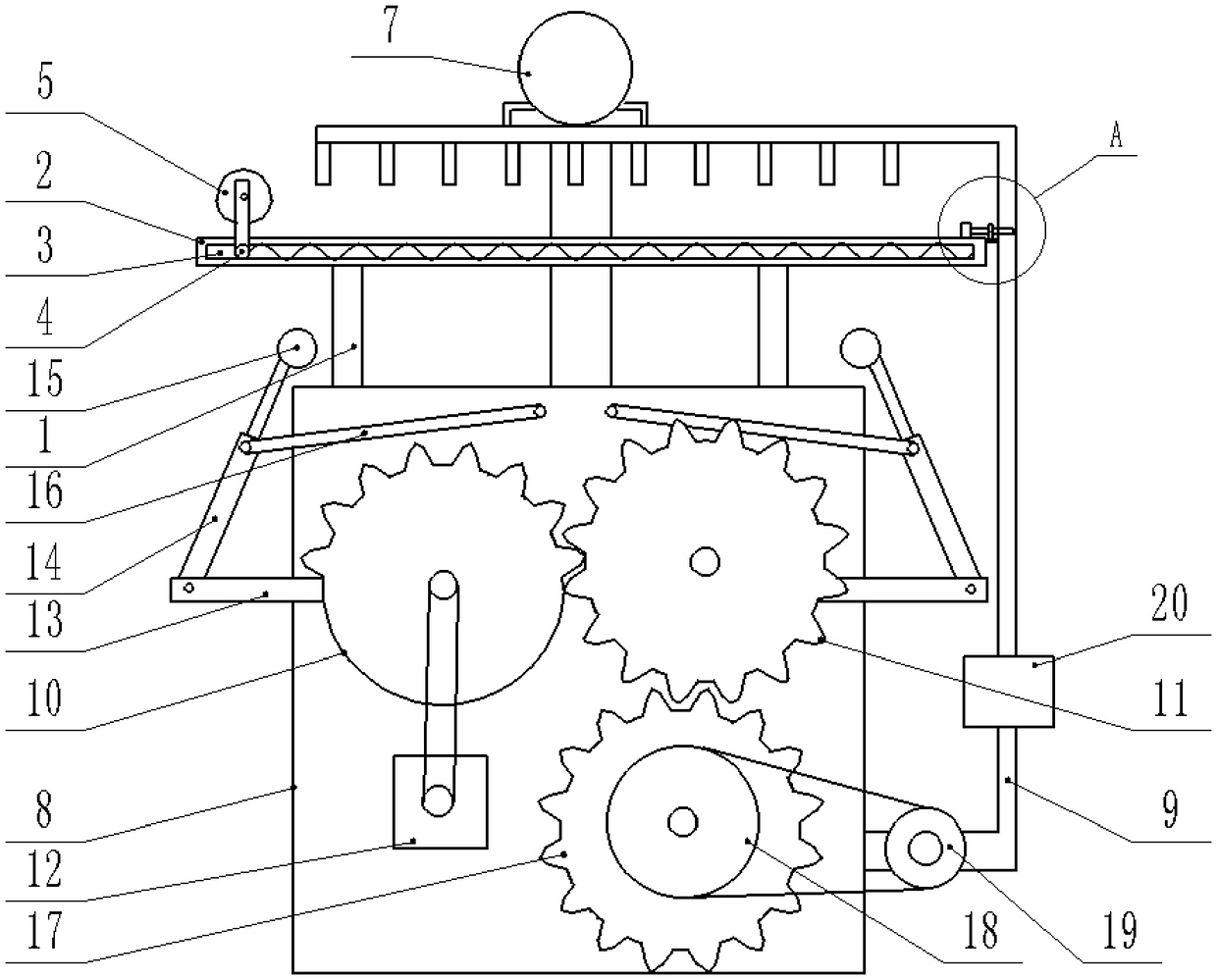

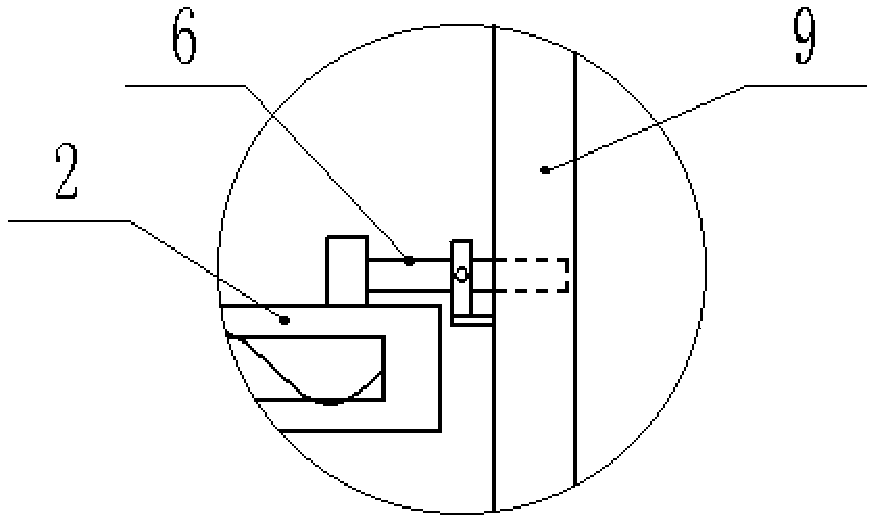

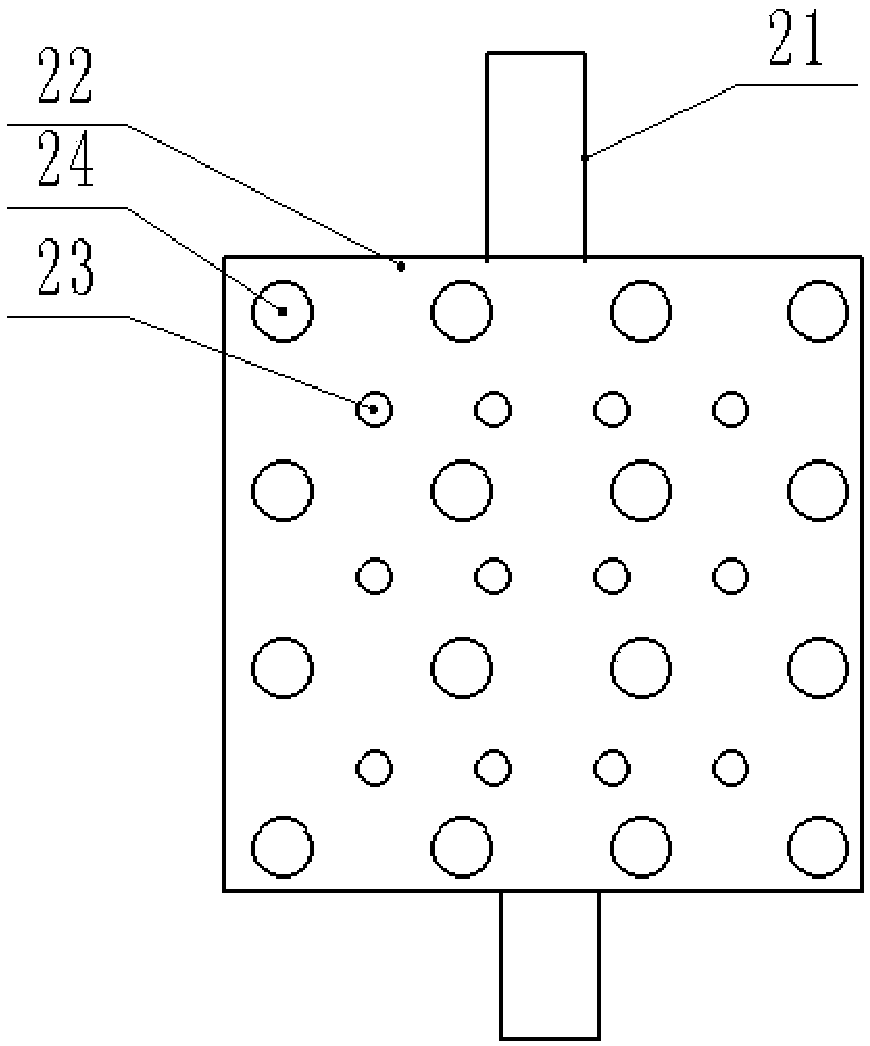

[0020] The reference signs in the drawings of the description include: processing table 1, platen 2, slide rail 3, slide shaft 4, application roller 5, pressing plate 6, air bag 7, paint box 8, paint spraying tube 9, first gear 10, the first Second gear 11, motor 12, support arm 13, push rod 14, ball 15, support rod 16, third gear 17, belt pulley 18, valve 19, liquid pump 20, main shaft 21, stirring plate 22, sieve hole 23, convex from 24.

[0021] The embodiment is basically as figure 1 Shown: a painting device for the main box board, including a paint box 8, the paint spray pipe 9 is fixedly connected to the bottom of the right side of the paint box 8, and the top of the paint box 8 is welded with a processing table 1. The outer wall of the paint box 8 is rotatably connected with a meshing first gear 10 and a second gear 11 through bearings, the first gear 10 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com