Riveting and pressing integrated tool for air cover pressing

A windshield and riveting technology, which is applied to forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of complex operation steps, low work efficiency, long forming time, etc., to achieve strong flexibility, save labor, and save time and material effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

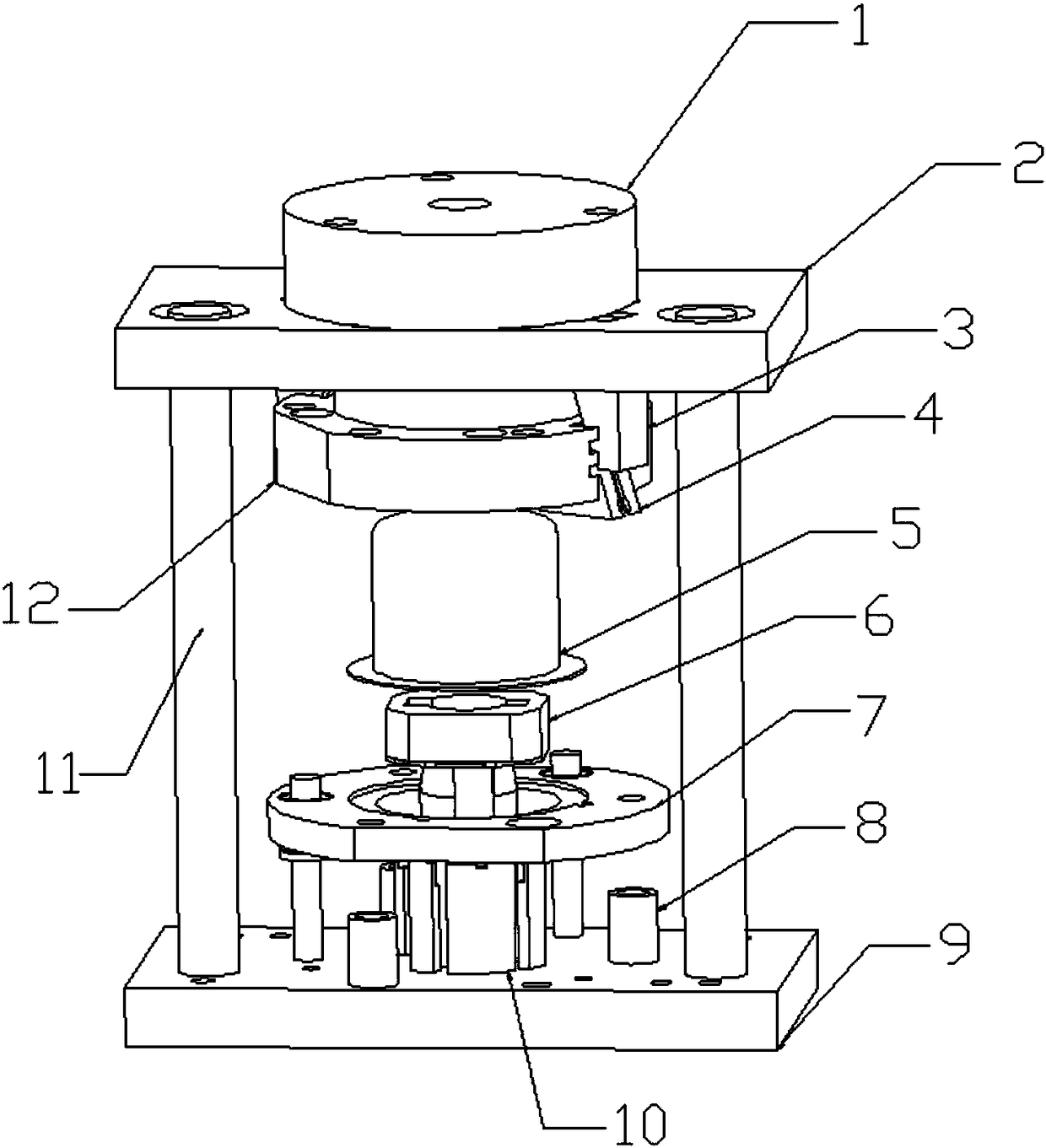

[0015] Example: such as figure 1 As shown, the present invention is a riveting integrated tooling for the air pressure cover, which includes an upper template 2 and a lower template 9 , and a positioning column 10 is provided on the upper part of the lower template 9 for positioning the fixing seat 7 . One side of the positioning column 10 is provided with a limiting column 8, which is used to limit the position of the fixing seat 7 and prevent the fixing seat 7 from continuing to move downward. The top of the positioning column 10 is connected to the fixed seat 7, and the fixed seat 7 is provided with a stator 6, which is used to generate an exciting magnetic field and exert a force on the current-carrying conductor therein. The upper part of the stator 6 is provided with a windshield 5, and the lower formwork 9 is connected with the upper formwork 2 through a connecting column 11, and the upper formwork 2 is provided with a cylinder connection block 1 for connecting with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com