Collaborative robot joint position stopper

A technology of robot joints and stoppers, applied in the direction of manipulators, manufacturing tools, etc., can solve the problems of large installation space, inability to comply with the development trend of integrated collaborative robots, and complex structure, so as to reduce installation space, compact structure, and improve reliability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

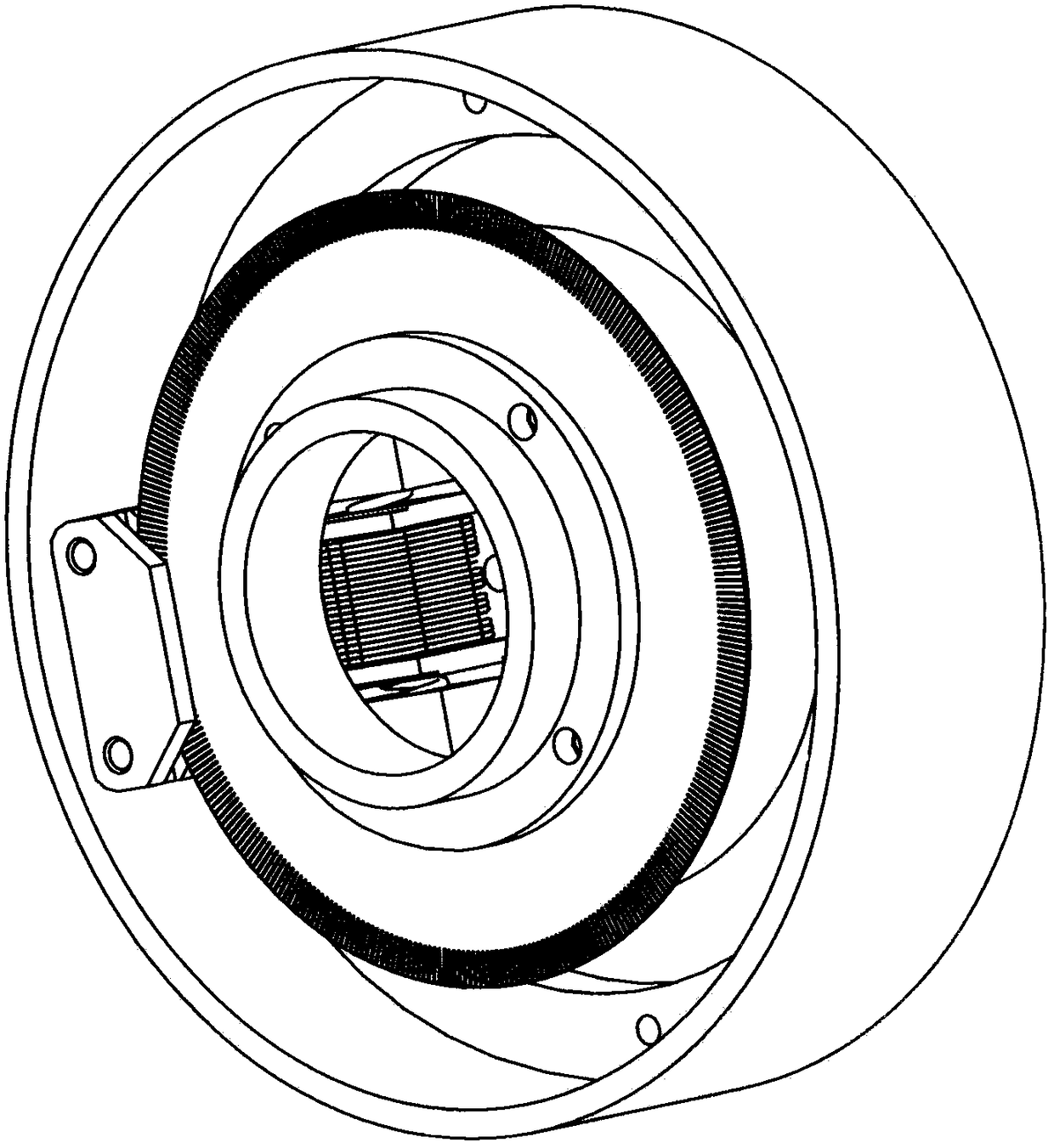

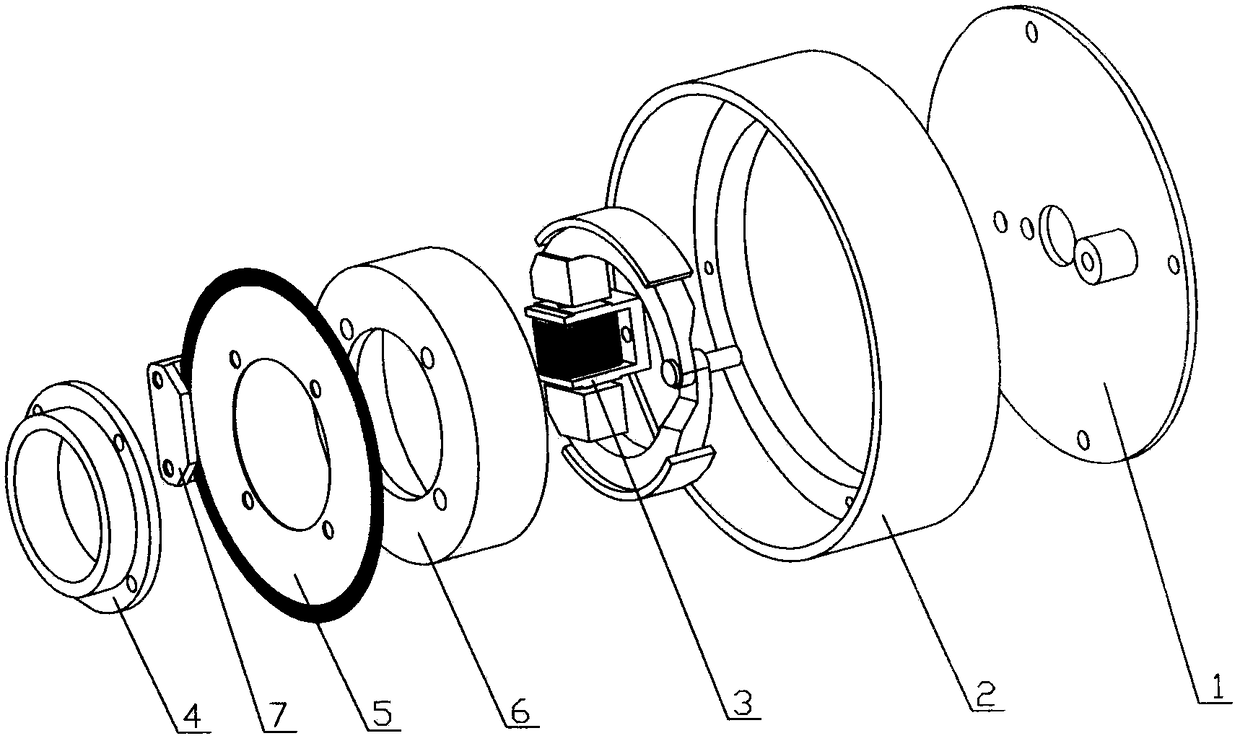

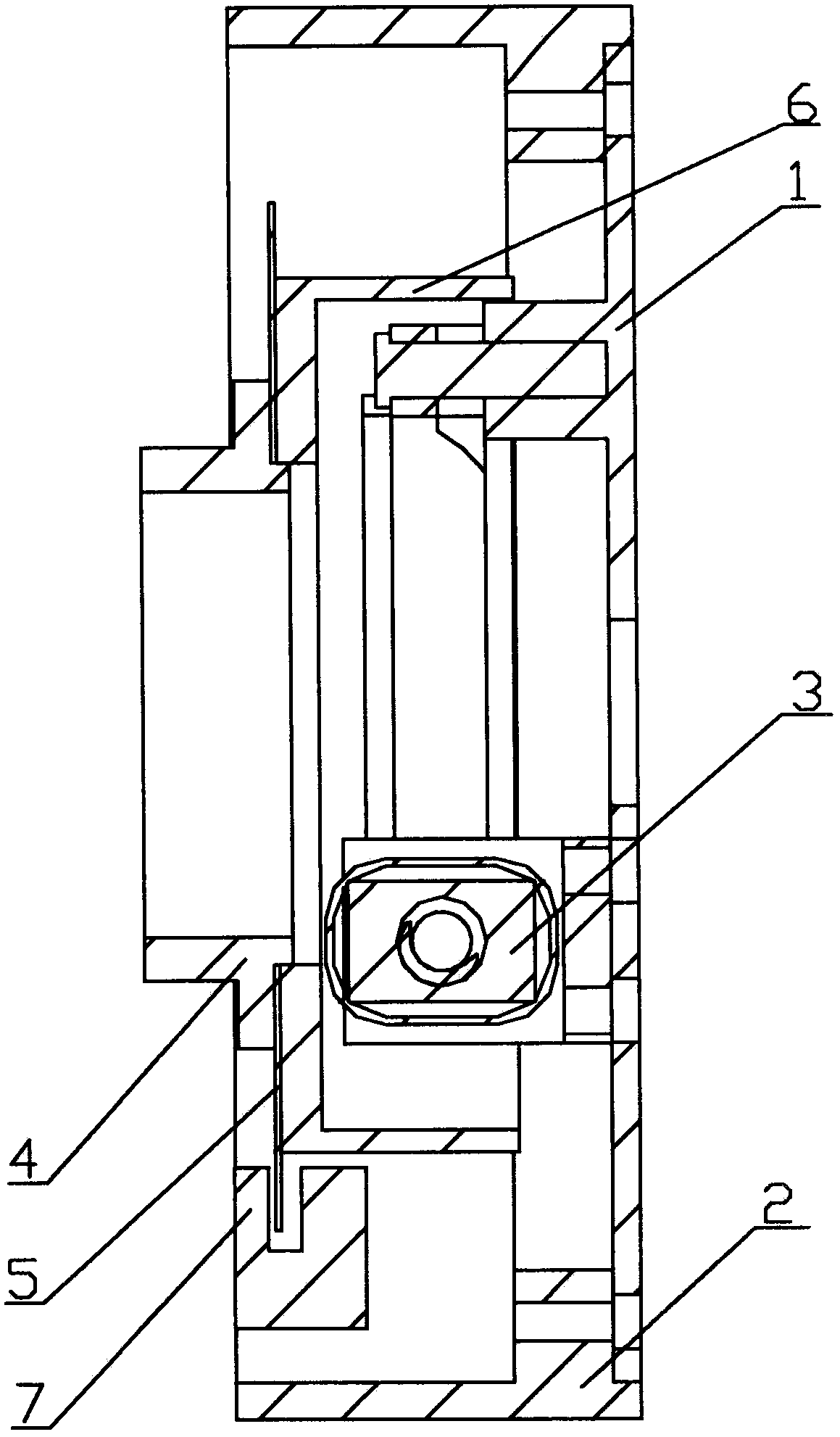

[0014] Such as Figure 1-Figure 4 As shown, this specific embodiment adopts the following technical solutions: it includes a base plate 1, a housing 2, an electromagnetic expansion brake device 3, a rotor shaft 4, a circular grating 5, a brake disc 6 and a grating read head 7, and the base plate 1 It is fixedly connected with the housing 2, and the inner side of the bottom plate 1 is fixedly installed with an electromagnetic expansion brake device 3. The rotor shaft 4, the circular grating 5 and the brake disc 6 are fixedly connected, and the circular grating 5 is installed on the rotor shaft 4 and the brake disc 6. In the middle of the brake disc 6, a grating reading head 7 is installed on one side of the circular grating 5, and the grating reading head 7 can be fixedly installed on the robot joint housing, wherein the electromagnetic expansion brake device 3 includes a spring 301, an electromagnet 302, armature 303, expansion brake body 304, brake pad 305 and pin shaft 306, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com