Heat pump type dish washing machine

A dishwasher and heat pump type technology, applied in the field of kitchen equipment, can solve the problems of disadvantage, high manufacturing cost and processing technology requirements, low heat transfer efficiency of washing water, etc., achieve simple processing and installation process, improve washing water Effect, easy removal and installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

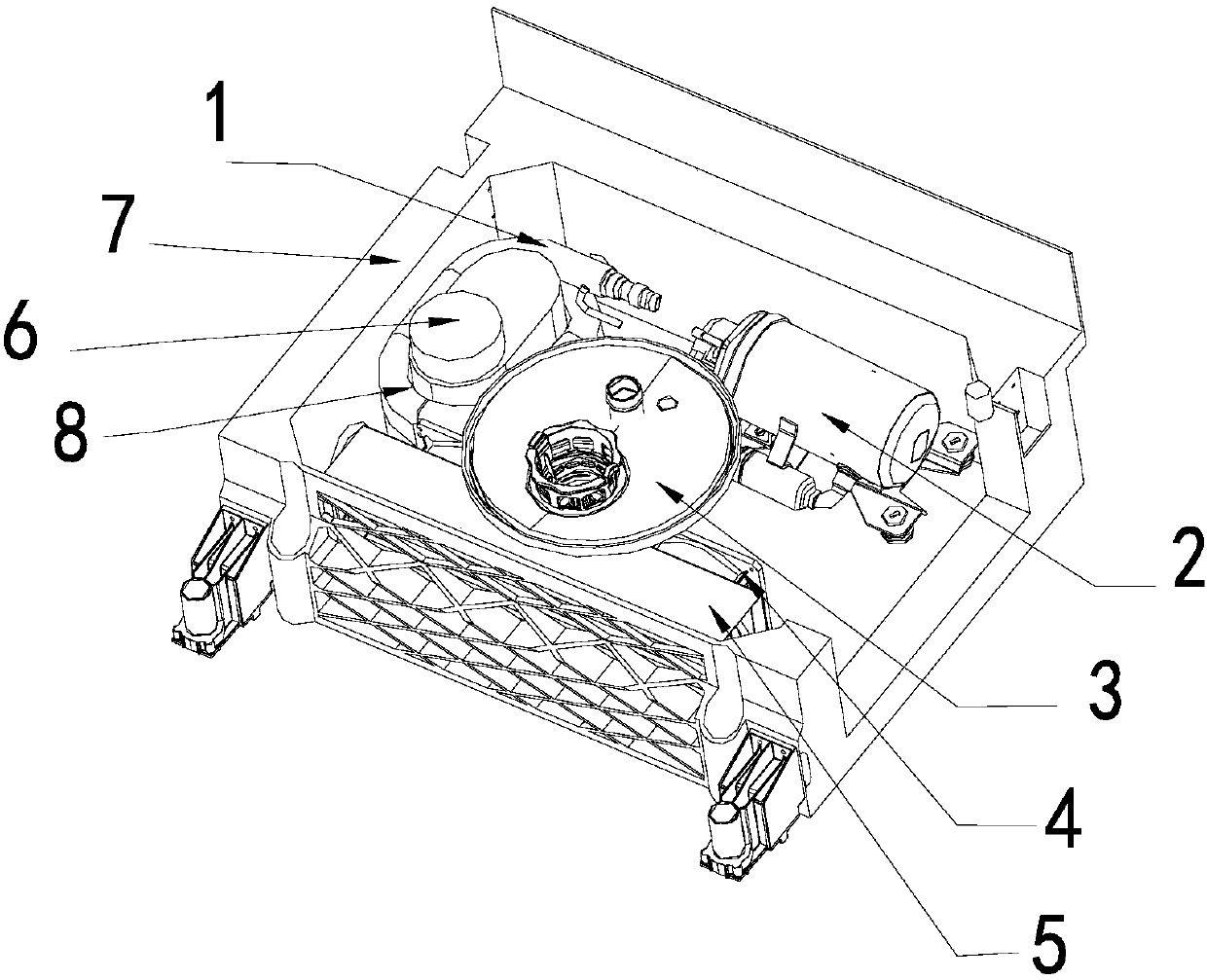

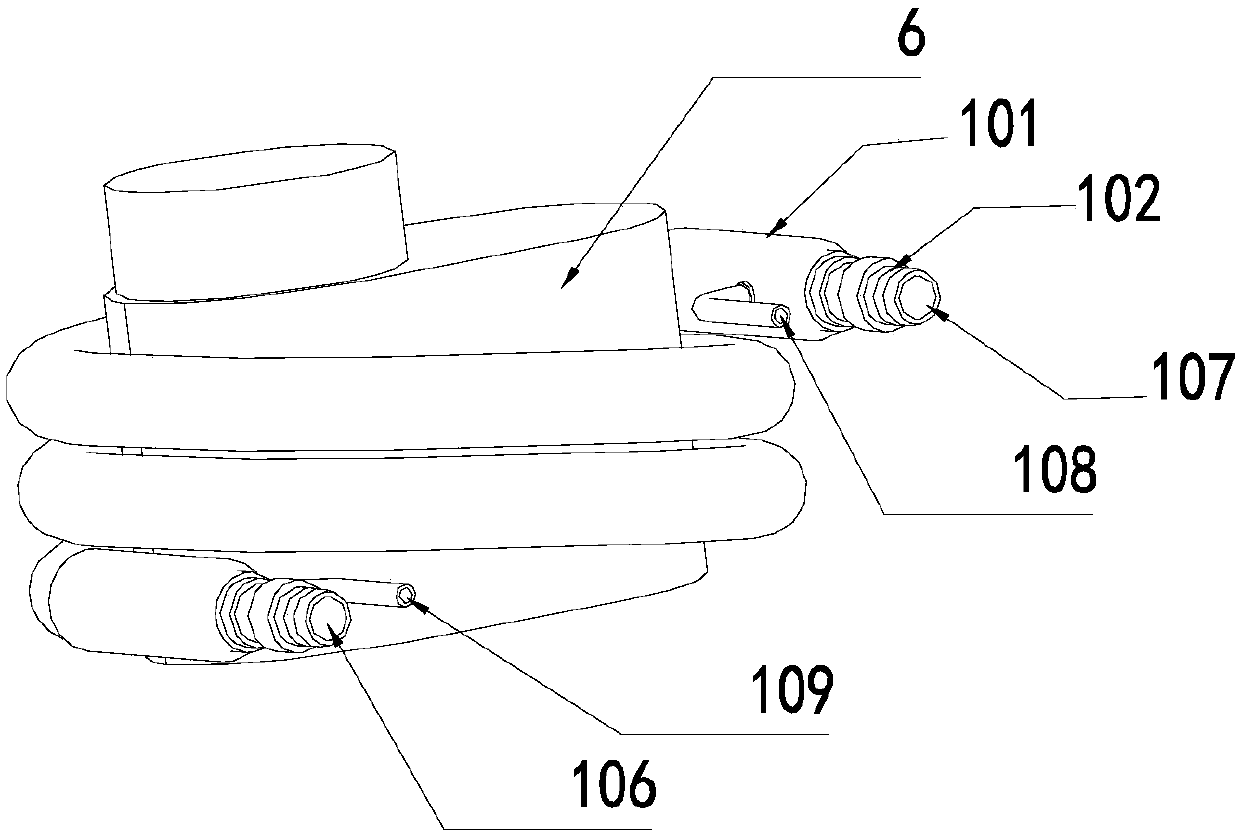

[0050] Such as Figure 1 to Figure 3 As shown, a heat pump dishwasher is disclosed in this embodiment. The dishwasher includes a treatment chamber not shown in the figure; the treatment chamber is provided with a spray port, and the spray port sprays the washing water provided by the washing water channel to clean the tableware located in the treatment chamber. The washing water circuit is connected with a water inlet valve, a respirator, a drainage pump, a circulating pump and a spray port. The washing water enters the washing water channel through the water inlet valve, flows into the treatment chamber equipped with tableware, circulates the washing water in the washing water channel through the circulation pump, and sprays the tableware on the tableware through the spray port. After cleaning, the dirty water is discharged through the drain pump, and the respirator is used to prevent siphoning of the washing water channel.

[0051] Such as figure 1 As shown, the softening...

Embodiment 2

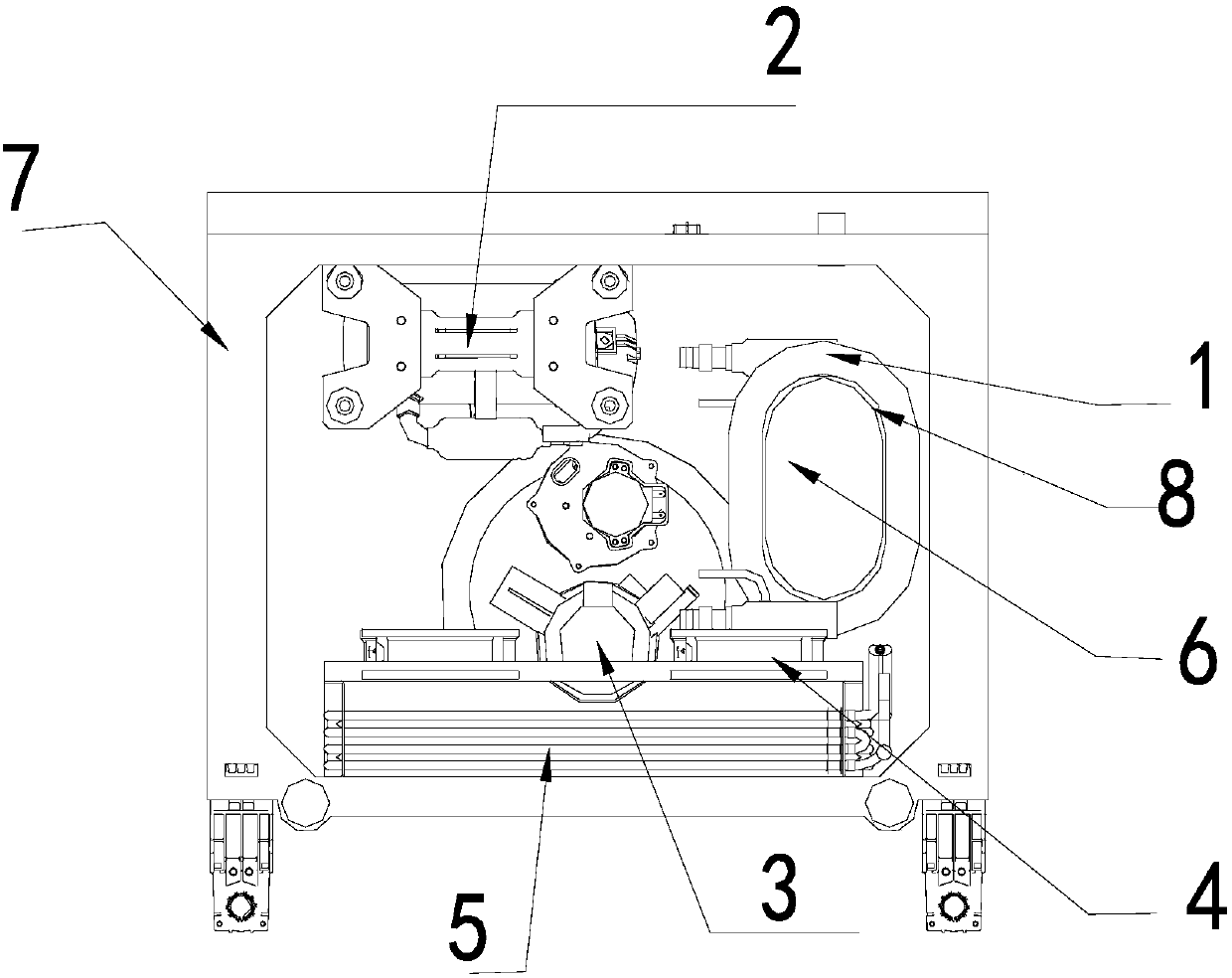

[0062] Such as Figure 4 As shown, a heat pump dishwasher is disclosed in this embodiment. The dishwasher includes a processing chamber not shown in the figure; the processing chamber is provided with a spray port, and the spray port is provided with washing water through a washing water channel to spray and clean the tableware located in the processing chamber. The washing water circuit is connected with a water inlet valve, a respirator, a drainage pump, a circulating pump and a spray port. The washing water enters the washing water channel through the water inlet valve, flows into the treatment chamber equipped with tableware, circulates the washing water in the washing water channel through the circulation pump, and sprays the tableware on the tableware through the spray port. After cleaning, the dirty water is discharged through the drain pump, and the respirator is used to prevent siphoning of the washing water channel.

[0063] In order to improve the cleaning effect ...

Embodiment 3

[0075] Such as Figure 4 to Figure 7 As shown, the exterior of the evaporator in this embodiment is provided with a plurality of fans 4 for accelerating the air flow on the surface of the evaporator 6, wherein at least two adjacent fans 4 are arranged at intervals. In this embodiment, the number of fans is two, and the size and / or power and / or model of the fans are the same.

[0076] Such as Figure 4 As shown, two fans 4 arranged at intervals are arranged side by side on the same side of the heat exchange surface of the evaporator 5 to accelerate the air flow velocity on the heat exchange surface of the evaporator 5 near the fans 4 . The side-by-side arrangement of the fans ensures the area of the accelerated air flow, thereby ensuring the working efficiency of the evaporator. At the same time, fan gaps 14 are formed between the fans arranged at intervals.

[0077] The dishwasher of the present invention comprises a treatment chamber for washing dishes, said treatment ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending angle | aaaaa | aaaaa |

| Bending angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com