Novel type low temperature booster pump gas bottle structure

A booster pump and low-temperature technology, which is applied in the field of cylinder structure of a new type of low-temperature booster pump, can solve problems such as leakage, failure of cantilever support joints, and large stress at welding points, so as to reduce large installation space, reduce failure probability, and improve The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

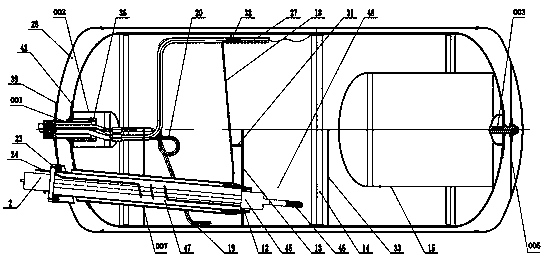

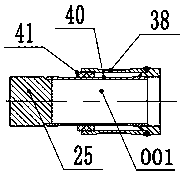

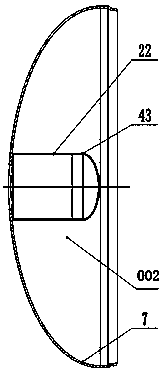

[0037] attached Figure 1-11 It is a specific embodiment of the present invention. The invention is a new type of low-temperature booster pump gas cylinder structure, including an inner container assembly 004, an outer container assembly 006, a reciprocating cryogenic booster pump 2, a pump support assembly 007, and a pipeline assembly. The outer container assembly 006 is equipped with a content Container assembly 004, an insulating interlayer 26 is provided between the outer container assembly 006 and the inner container assembly 004, a front end support assembly 001 is provided at one end between the outer container assembly 006 and the inner container assembly 004, and an inner rear head is provided at the other end Assembly 003, the reciprocating cryogenic booster pump 2 passes through the outer container assembly 006 and the inner container assembly 004, extends into the inner container assembly 004, and is supported by the pump support assembly 007 in the inner container...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com