Mold exhaust mechanism

A technology of exhaust mechanism and mold, which is applied in the field of mold exhaust mechanism, can solve the problems of long processing time, difficult assembly, cumbersome processing technology, etc., and achieve the effects of shortening processing time, simplifying processing technology, and simple assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

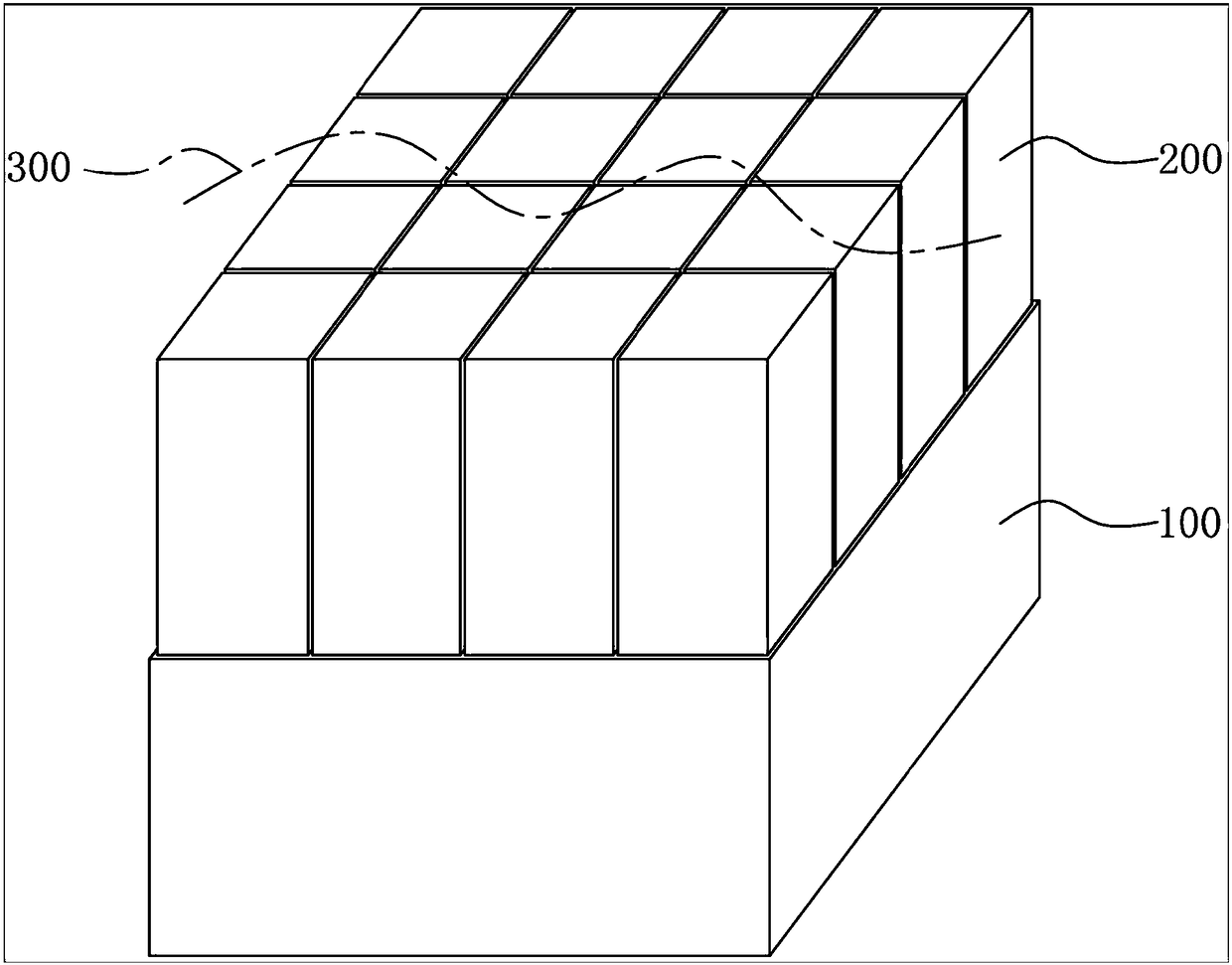

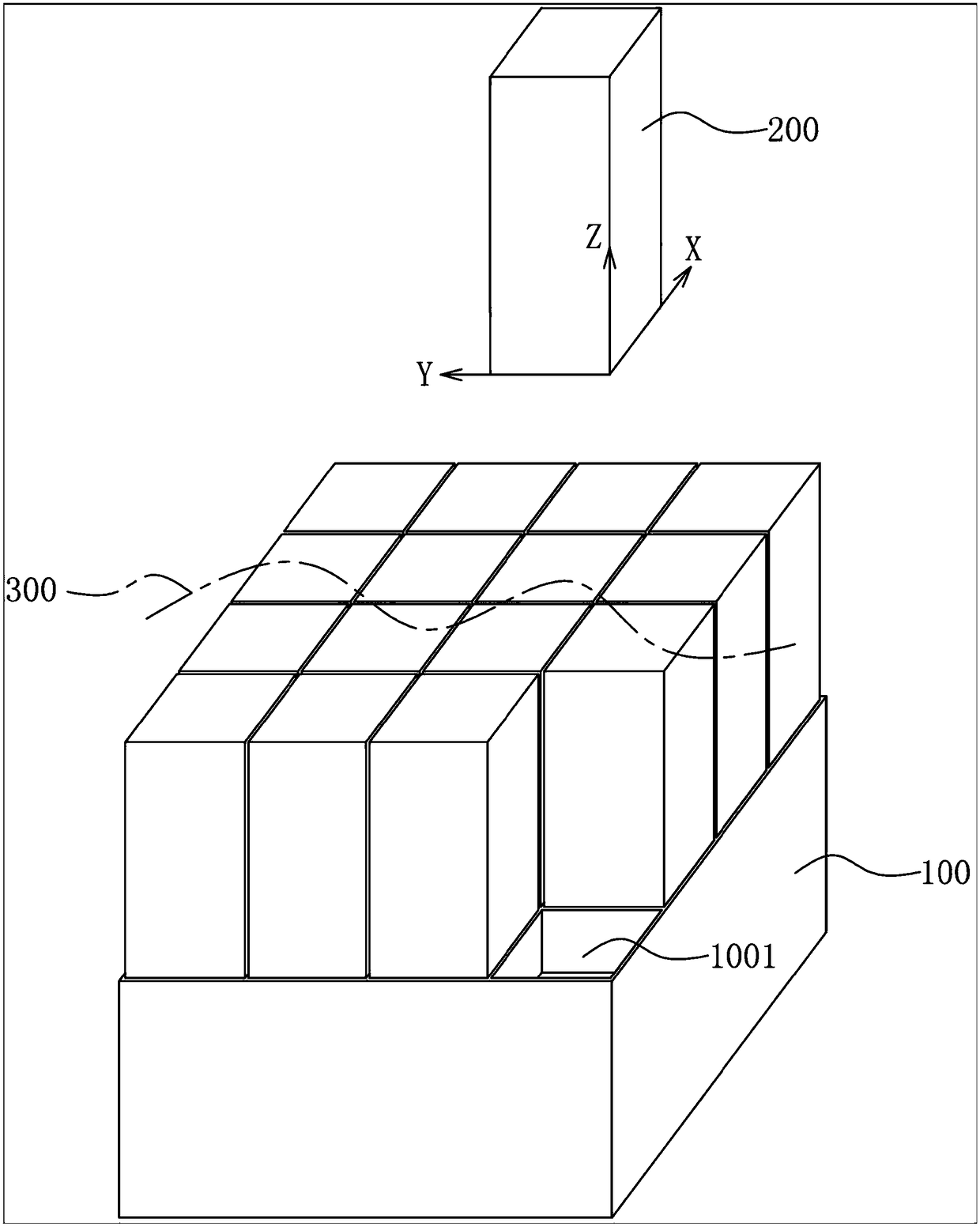

[0019] A mold exhaust mechanism of the present invention is applied in a mold. In this embodiment, the mold exhaust mechanism includes: an exhaust inlet base 100, and the exhaust inlet base 100 is provided with several Exhaust inlet sub-slot 1001, the exhaust inlet sub-slot 1001 is distributed in a grid shape; and a number of exhaust inlet sub-slots 200, the exhaust inlet sub-slot 200 is tightly fitted in the exhaust inlet sub-slot 1001 respectively, In this example, see figure 2 , the exhaust inlet 200 is partially placed in the exhaust inlet slot 1001, and the exhaust inlet 200 is a columnar body.

[0020] In this embodiment, the exhaust inlets 200 are respectively extended and arranged in the exhaust inlet sub slots 1001 in the transverse direction or the longitudinal direction.

[0021] In this embodiment, the distance between two adjace...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com