Labeling machine pipe taking device with soft start control function

A soft-start, labeling machine technology, applied in labeling machines, labels, packaging and other directions, can solve the problems of irregular hose arrangement, impact sound, affecting work efficiency, etc., to achieve online automation, no impact, reduce Effect of starting current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

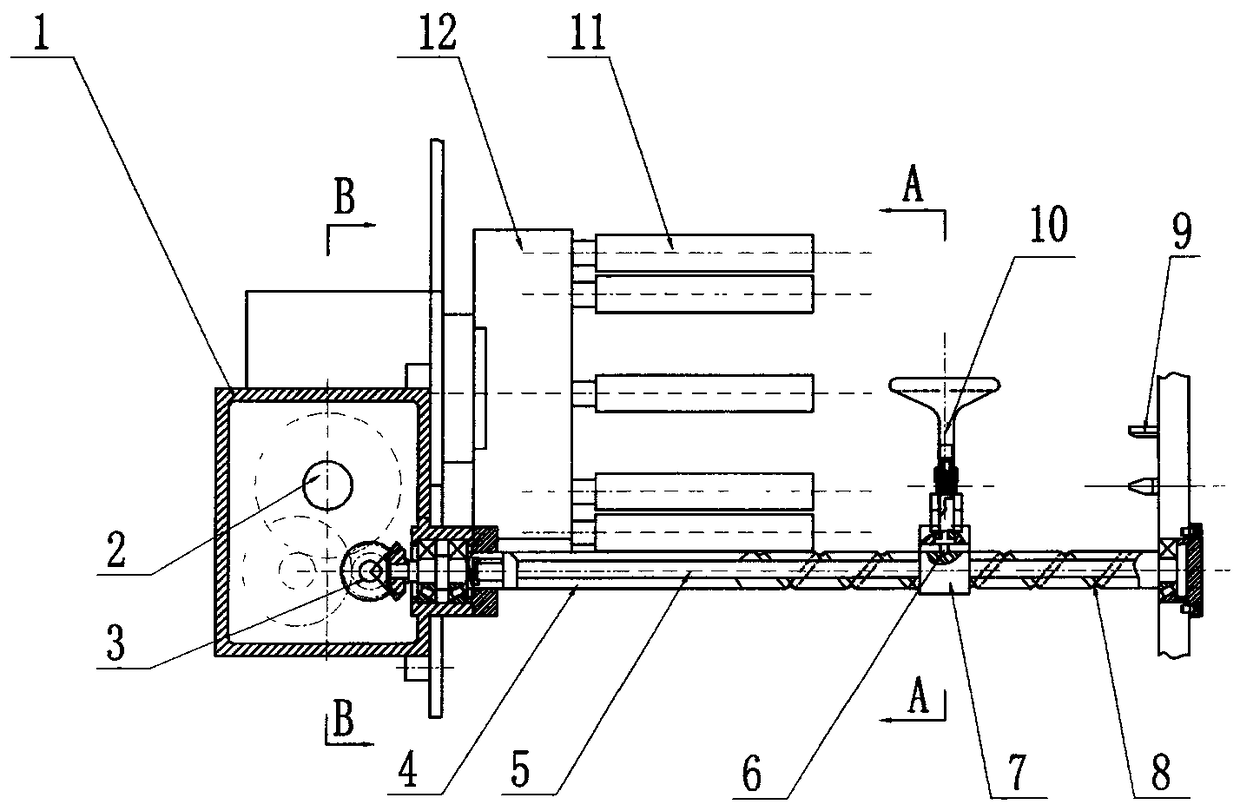

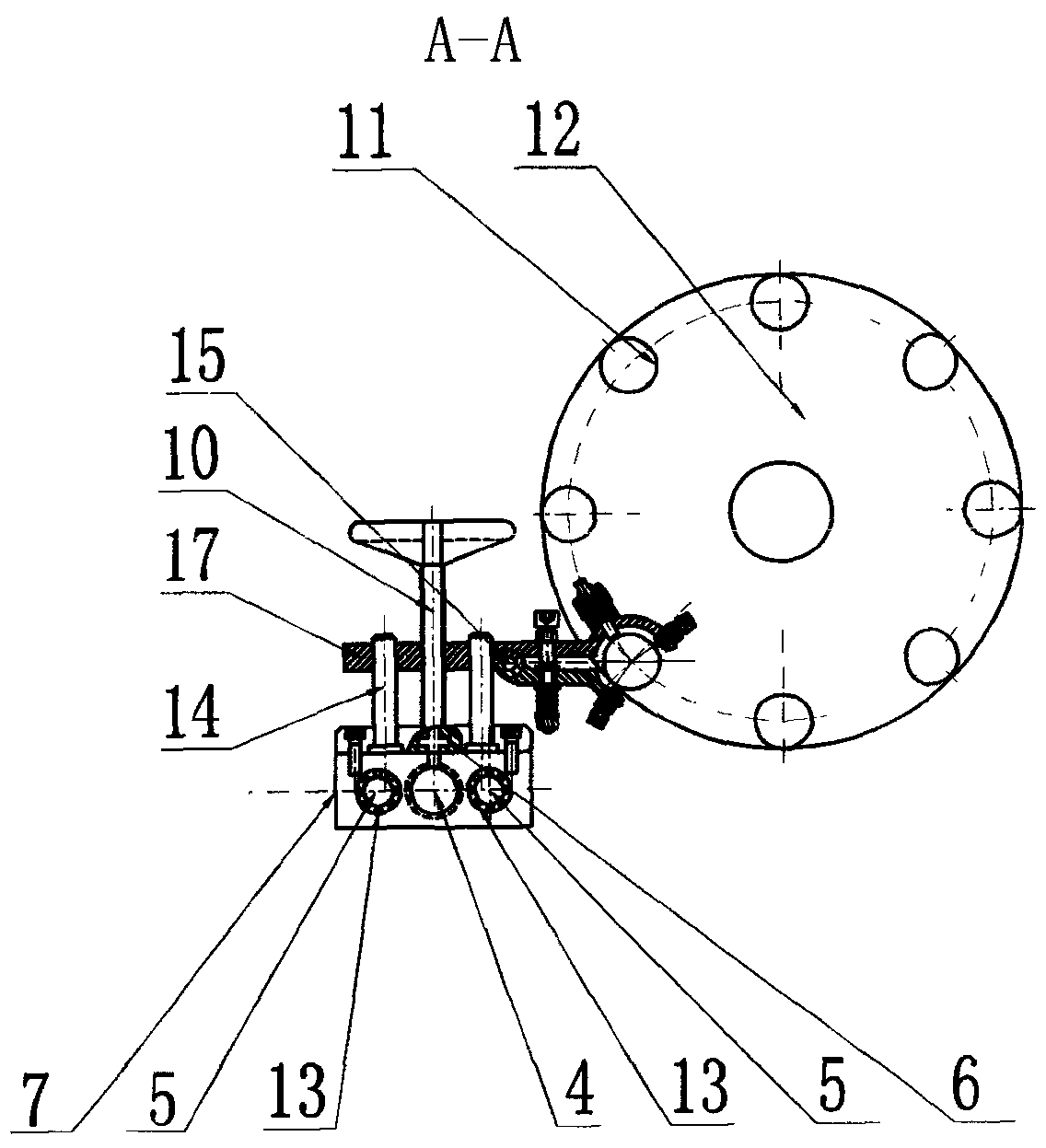

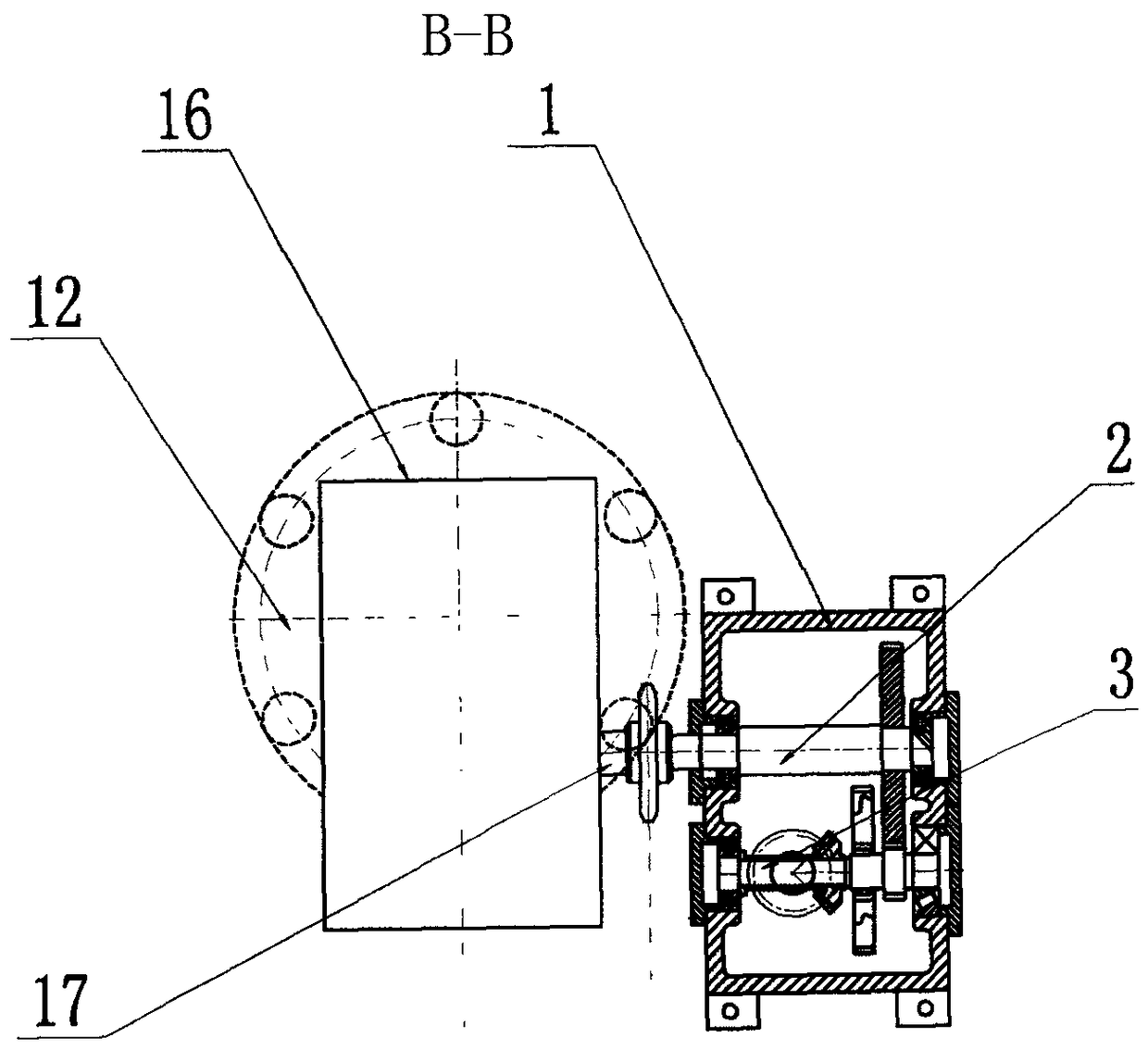

[0016] according to Figure 1~4 The specific structure of the present invention will be described in detail. The tube taking device of the labeling machine with soft start control includes a gearbox 1, a reciprocating rod 4, two guide columns 5, a slide seat 7, and a manipulator 15. The input shaft 2 of the gearbox 1 is connected with the input shaft 17 of the indexer 16, The output shaft 3 of the gearbox 1 is connected with the reciprocating rod 4, so that the rotation of the input shaft 17 of the indexer 16 drives the reciprocating rod 4 to make a circular motion through the gearbox 1, and the two guide posts and guide posts 5 are respectively arranged on both sides of the reciprocating rod 4 , the two sides of the slide seat 7 are respectively provided with linear bearings 13 matched with the two guide posts 5, and the middle part of the slide seat 7 is provided with a through hole matched with the reciprocating rod 4, so that the slide seat 7 can move along the two guide p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com