Computerized flat knitting machine lateral thread stand

A computerized flat knitting machine and edge frame technology, which is used in textile and papermaking, weft knitting, knitting and other directions, can solve the problems of reduced machine stability, reduced cloth quality, easy to break yarns, etc., and achieves long machine life and finished products. The effect of high rate and not easy to break yarn

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

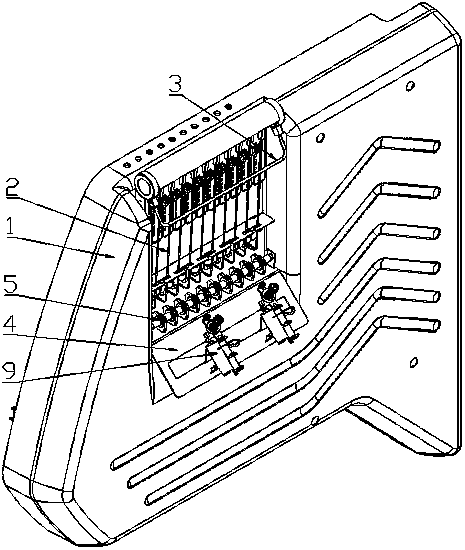

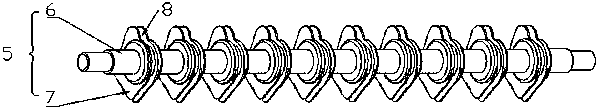

[0020] In this embodiment, preferably 10 rollers 7 and 10 jumpers 2 are preferred.

[0021] When the yarn passes through the thread groove 8 of the roller 7, because the roller 7 is rolling and connected to the axle 6, the flexible rotation of the roller 7 significantly reduces the yarn resistance, which can greatly reduce yarn breakage and uneven cloth.

[0022] The yarn is placed on the ground, and the yarn enters the flat knitting machine through the yarn breaker 9 and the guide wheel 5. The threading structure of the side frame greatly reduces the yarn resistance and effectively improves the quality of the knitted fabric.

[0023] The device can not only reduce the resistance when the yarn passes through the side frame, but also reduce the wear of the machine head, reduce the damage of the knitting needle, extend the service life of the machine, and reduce the operating cost of the enterprise.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com