Steel structure roof framework

A steel structure and frame technology, applied in building construction, theaters, buildings, etc., can solve the problems of inability to perform secondary adjustment, inconvenient use, and high difficulty, and achieve the effect of reasonable structure, convenient production, and reduced difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Obviously, the described embodiments It is a part of embodiments of the present invention, but not all embodiments.

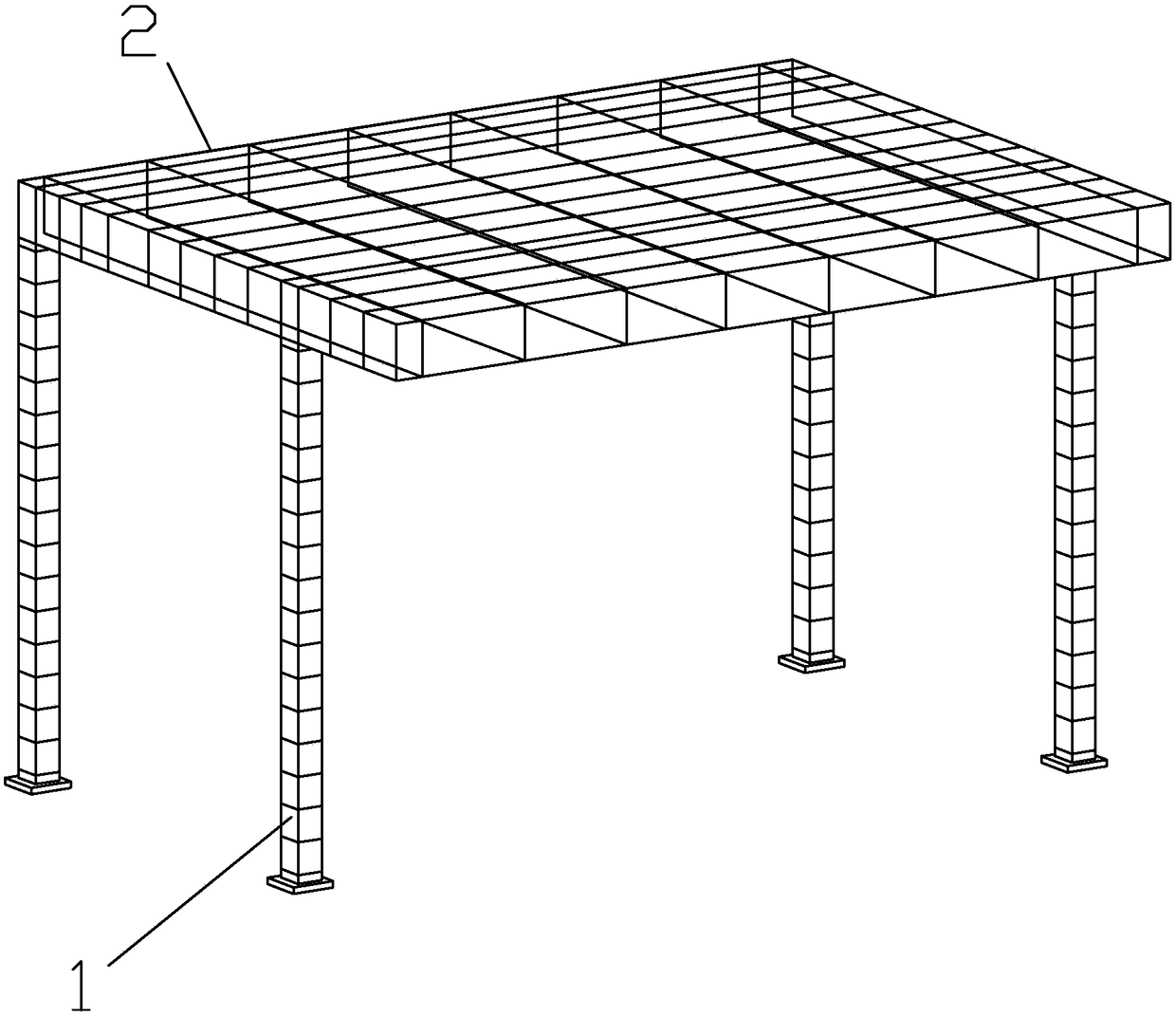

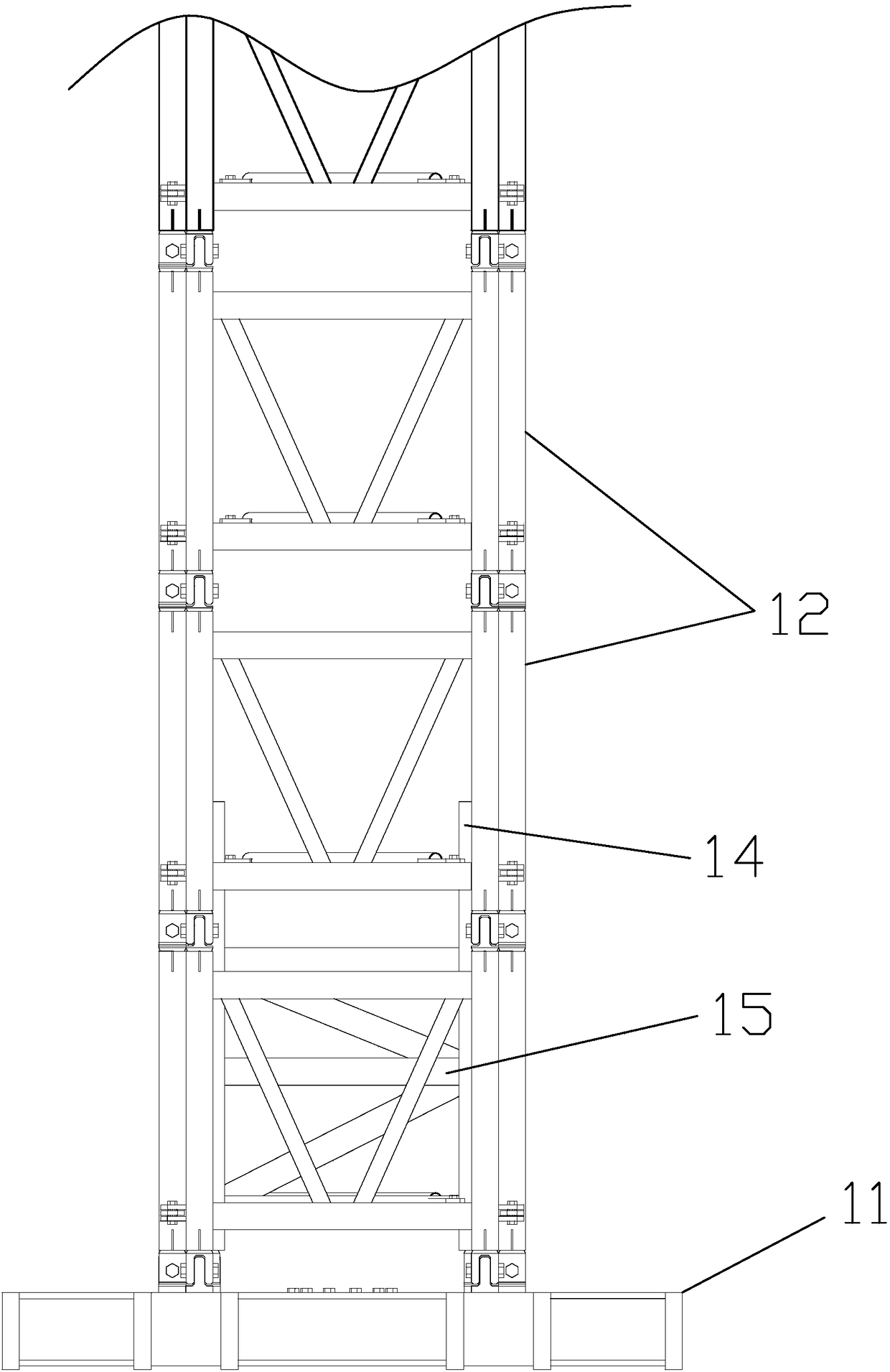

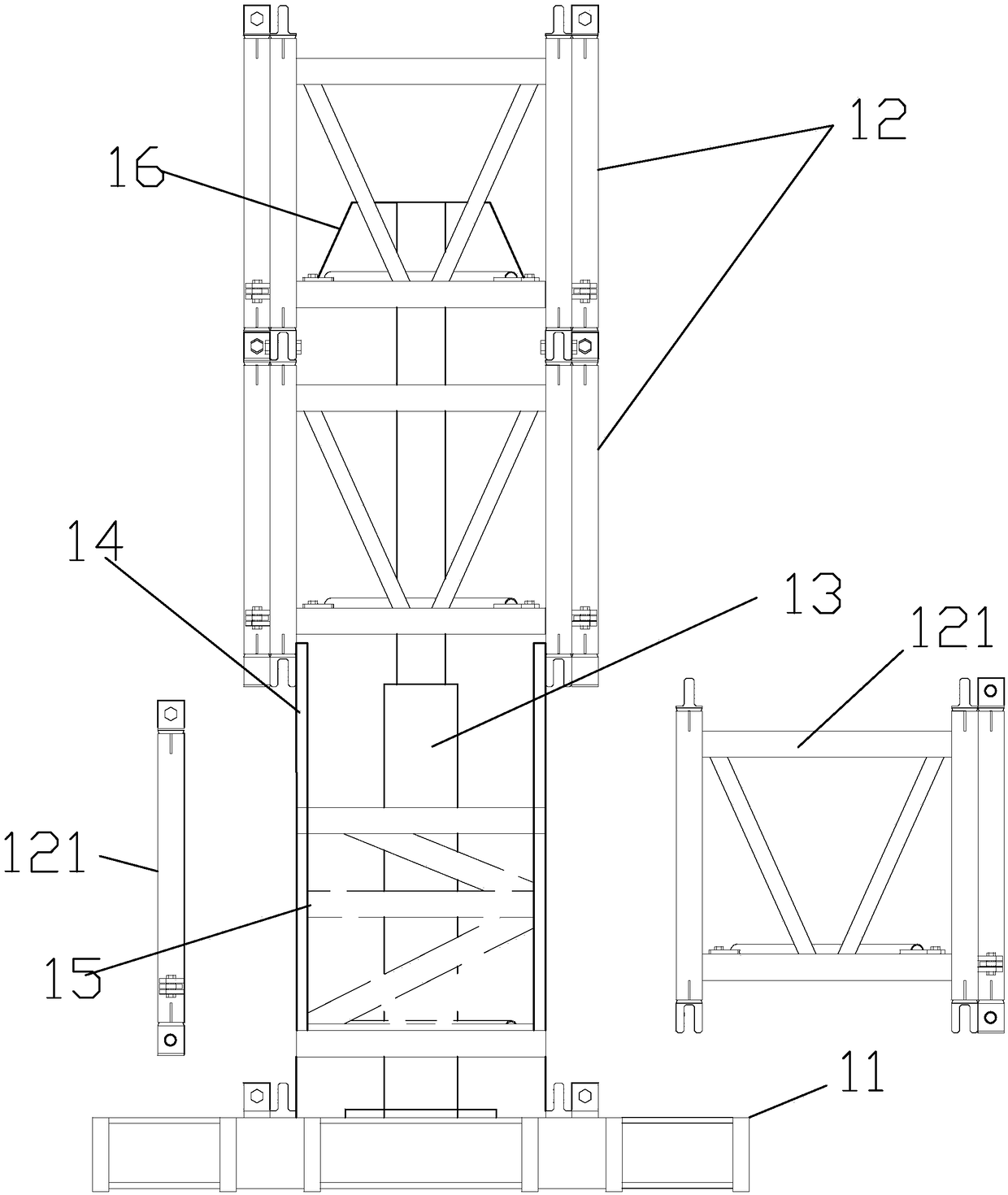

[0022] refer to Figure 1 to Figure 7 , the present embodiment discloses a roof frame of a steel structure, including four stand 1 standing on the ground and a ceiling 2 arranged on the top of the stand 1, the stand 1 includes a base 11, a plurality of sets On the support frame 12 on the base 11, a plurality of support frames 12 are stacked from bottom to top to the top, the number of support frames 12 increases or decreases according to the height requirements, and the bottom of the previous support frame 12 passes through the top of the next suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com