Pump body component and compressor with it

A technology of components and pump bodies, applied in the field of compressors, can solve the problems of detachment of the inner wall of the sliding vane cylinder and the reduction of the working performance of the pump body components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

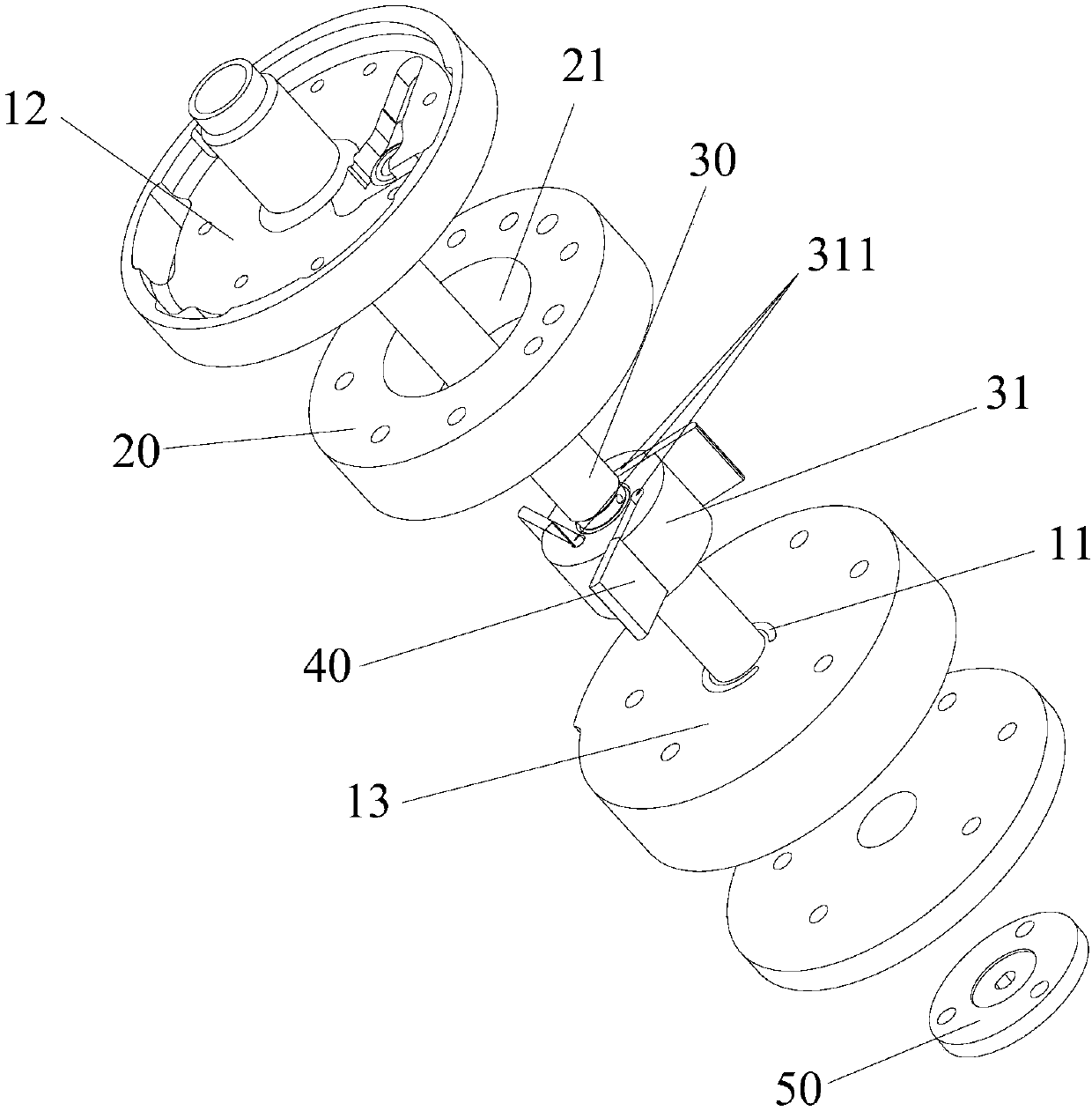

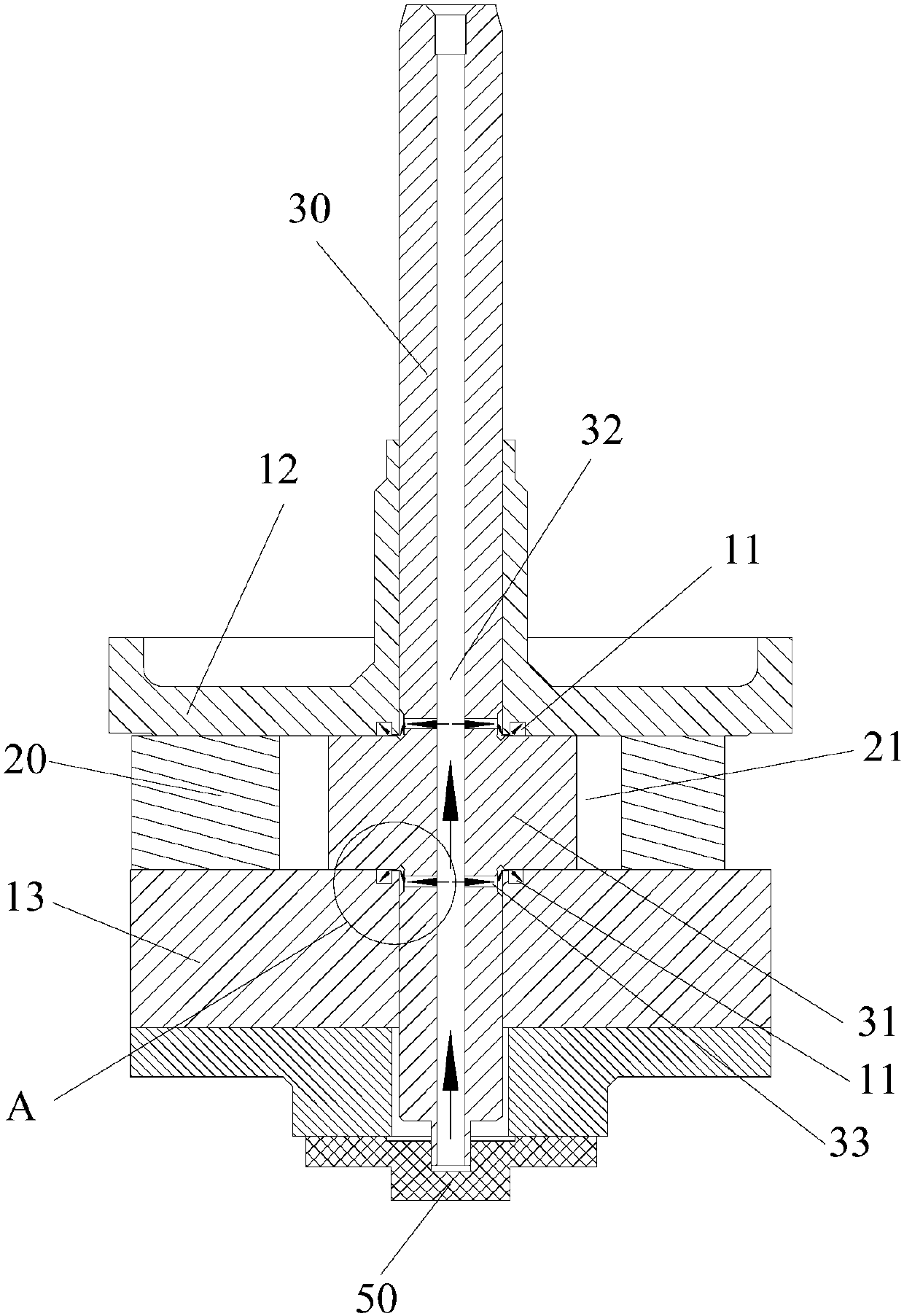

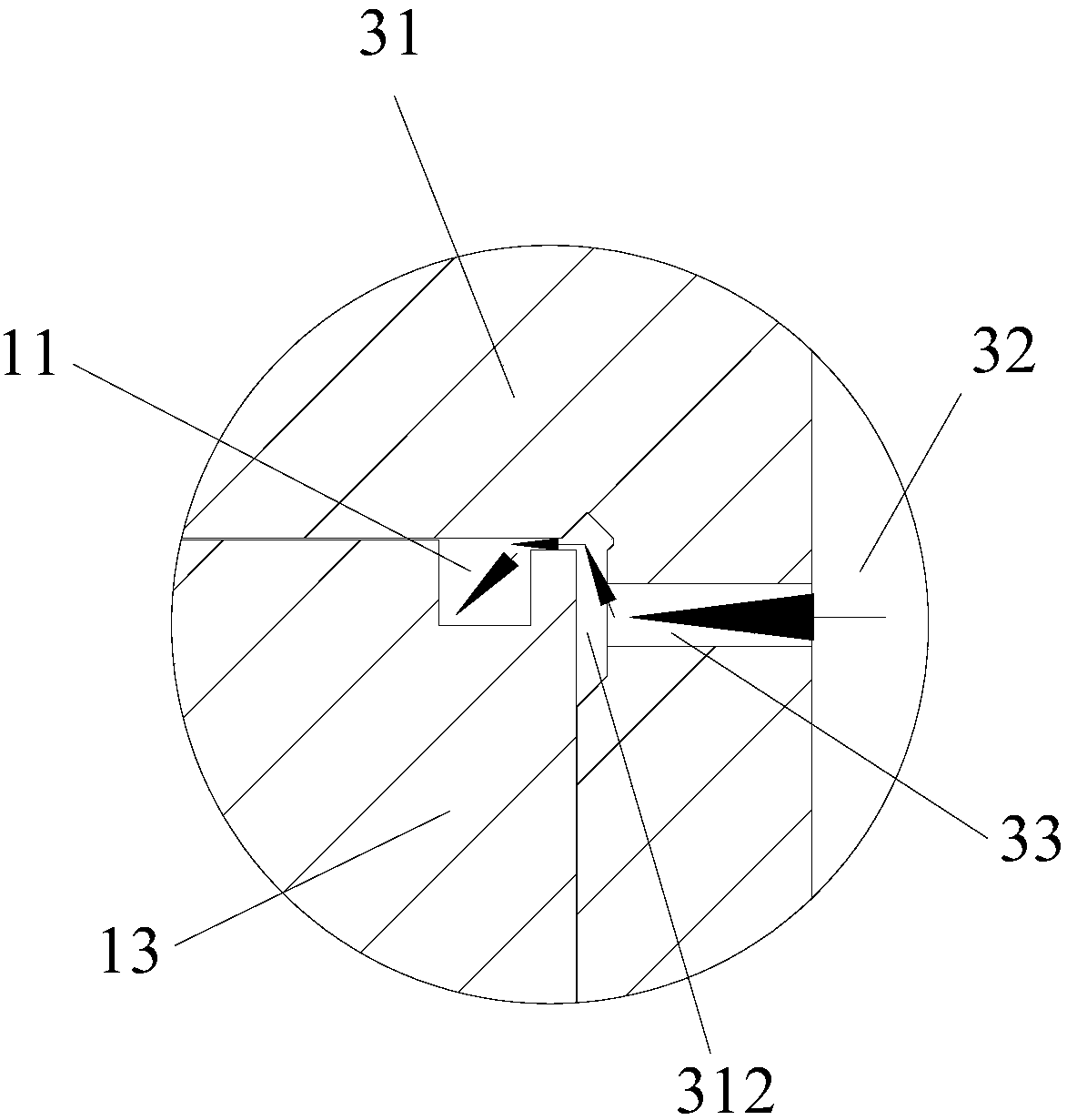

[0051] Such as Figure 1 to Figure 6 As shown, the pump body assembly includes a structural member, a cylinder 20 , a rotating shaft 30 and a plurality of sliding vanes 40 . Among them, there are two structural parts, at least one structural part has a back pressure oil structure, the back pressure oil structure is a back pressure arc groove 11, and the arc number φ1 of the back pressure arc groove 11 is greater than or equal to 220°. The cylinder 20 is arranged between the two structural members. The rotating shaft 30 passes through the two structural components and the cylinder 20 , and the rotor portion 31 of the rotating shaft 30 has a plurality of slide slots 311 . A plurality of sliding vanes 40 are slidably arranged in a plurality of sliding vane grooves 311, part or all of the back pressure arc grooves 11 communicate with the sliding vane grooves 311, and lubricating medium can enter into the back pressure arc grooves 11 to adjust the sliding vane grooves The pressur...

Embodiment 2

[0071] The difference between the pump body assembly of the second embodiment and the first embodiment is that the structure of the back pressure arc groove 11 is different.

[0072] Such as Figure 12 to Figure 14 As shown, the back pressure arc grooves 11 are connected end to end to form an annular groove. In this way, the lubricating medium can enter into the annular groove, circulate in the annular groove and take away the heat in the cylinder 20, thereby reducing the temperature inside the cylinder 20, cooling and cooling the cylinder 20, and improving the working efficiency of the pump body components. performance. At the same time, the above-mentioned structure is simple in structure, easy to process and realize, and further reduces the processing cost of the pump body assembly.

[0073] Such as Figure 12 to Figure 14As shown, the annular groove includes a first arc groove section 111 and a second arc groove section 112 that communicate with each other, and the sum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com