Hydraulic servo drive system for precision model support device

A technology of support device and hydraulic servo, which is used in the safety of fluid pressure actuation system, components of fluid pressure actuation system, servo motors, etc., can solve the problems of low motion accuracy and poor support rigidity, and achieve high position control accuracy and improved The effect of structural support stiffness and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

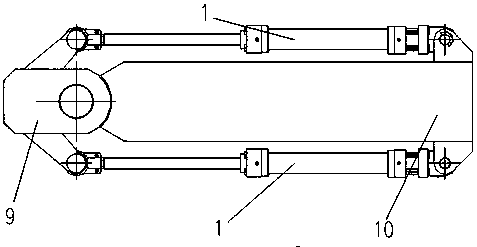

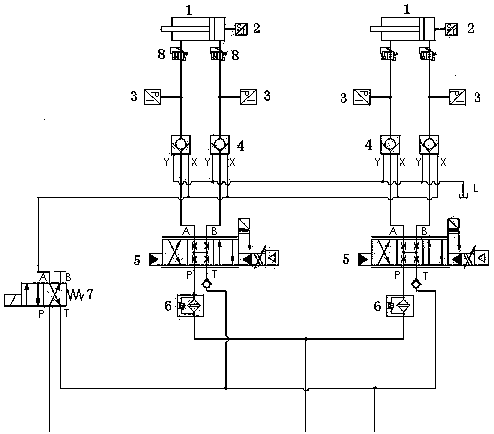

[0012] like figure 1 As shown, the present invention is a hydraulic servo drive system for a precision model support device, including two groups of hydraulic cylinders 1 connected to the swinging member 9 and the fixing member 10, and each group of hydraulic cylinders 1 is correspondingly connected to a servo valve 5 , each group of hydraulic cylinders 1 controls the motion state through its own servo valve, each group of hydraulic cylinders 1 is equipped with a displacement sensor 2 and a pressure sensor 3, and the real-time position feedback is performed through the displacement sensor 2, and the hydraulic cylinder 1 is output through the pressure sensor. Each group of hydraulic cylinders 1 is equipped with an explosion-proof valve 8 at the connection port to prevent abnormal movement of the equipment when the connecting pipeline is damaged. A hydraulic lock 4 is installed between each group of hydraulic cylinders 1 and its corresponding servo valve 5, and Controlled by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com