Oil supply device

A technology of oil supply device and oil tank, which is applied in the direction of bearing components, engine components, engine lubrication, etc., can solve the problems of lubricating oil waste and intermittent oil supply, etc., achieve a firm structure, prevent continuous oil dripping, and ensure uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following is further described in detail through specific implementation methods:

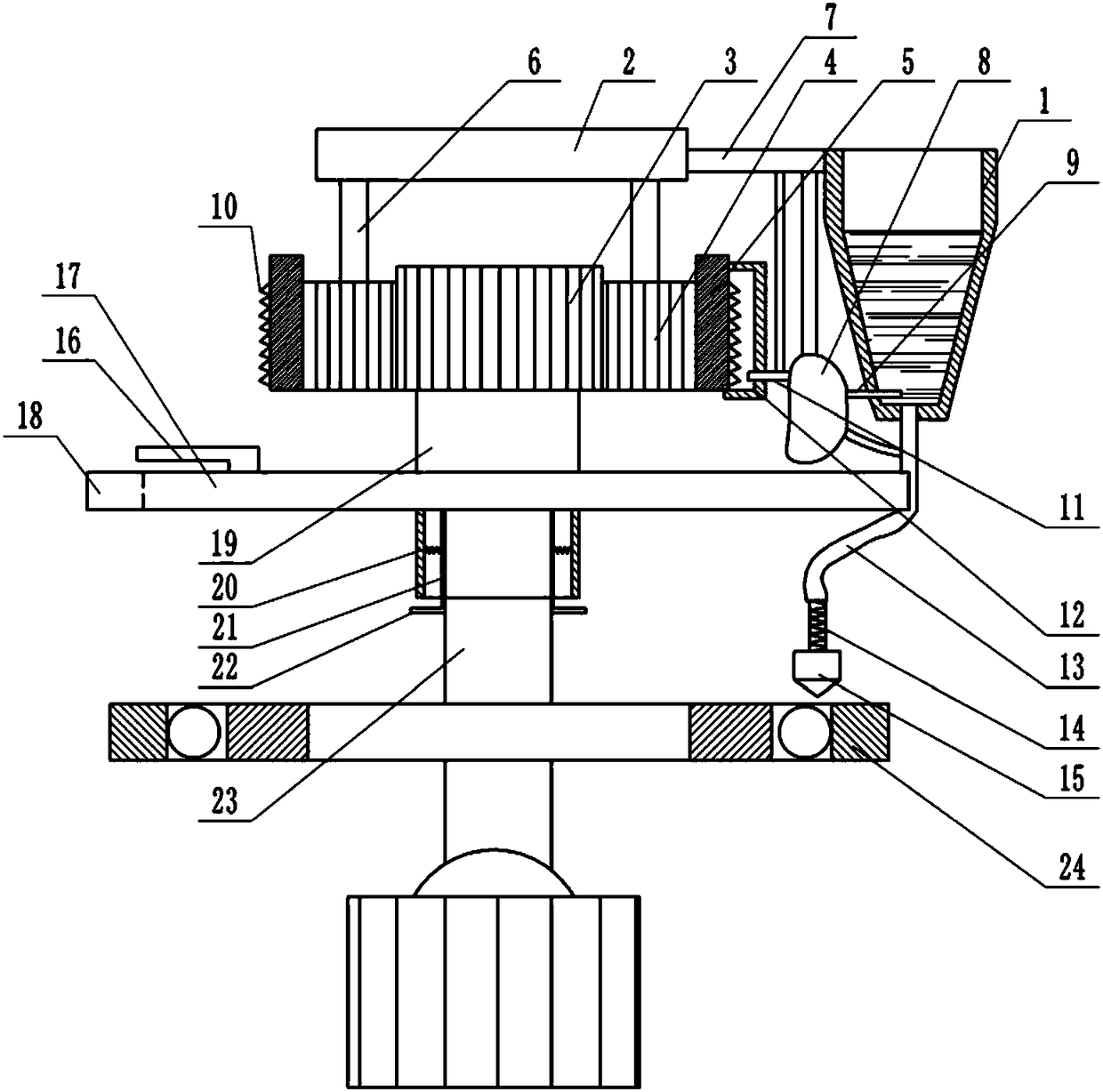

[0015] The reference signs in the drawings of the description include: fuel tank 1, fixed plate 2, main gear 3, external gear 4, internal gear 5, rotating shaft 6, connecting plate 7, air bag 8, oil control plate 9, locking teeth 10, ejector rod 11 , rotating block 12, hose 13, telescopic tube 14, oil cup 15, squeeze plate 16, squeeze plate 17, oil drain groove 18, clamping shaft 19, spring 20, clamping plate 21, button 22, drive shaft 23 , Bearing 24.

[0016] The embodiment is basically as attached figure 1 Shown: an oil supply device, including a fuel tank 1 and a clamping mechanism, the fuel tank 1 is filled with lubricating oil, the clamping mechanism includes a clamping shaft 19, the bottom of the clamping shaft 19 is provided with a clamping groove, and the clamping groove is provided with There are two clamping plates 21, a spring 20 is connected between the groove wall of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com