Method and system for measuring three-dimensional shape

A three-dimensional topography, measured object technology, applied in measuring devices, instruments, optical devices, etc., can solve problems such as coarse matching errors, and achieve the effect of improving uniqueness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

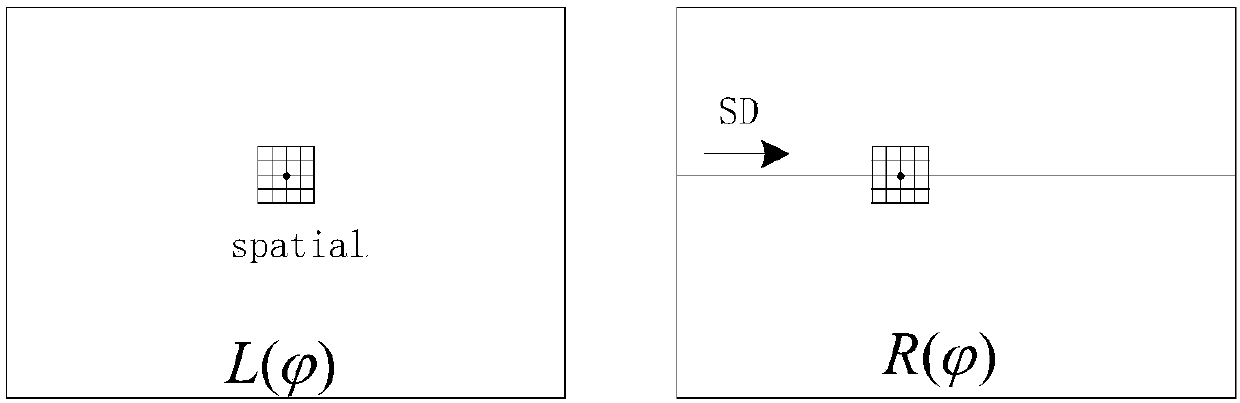

[0054]As mentioned above, when the object of 3D topography measurement is the measured object with illumination and / or appearance changes on the surface, since the stereoscopic image collected for it contains not only spatial axis information but also time axis information, therefore , if the two-dimensional matching window in the traditional stereo vision matching method is still used to complete the matching of pixel pairs, then the matching accuracy will inevitably be reduced.

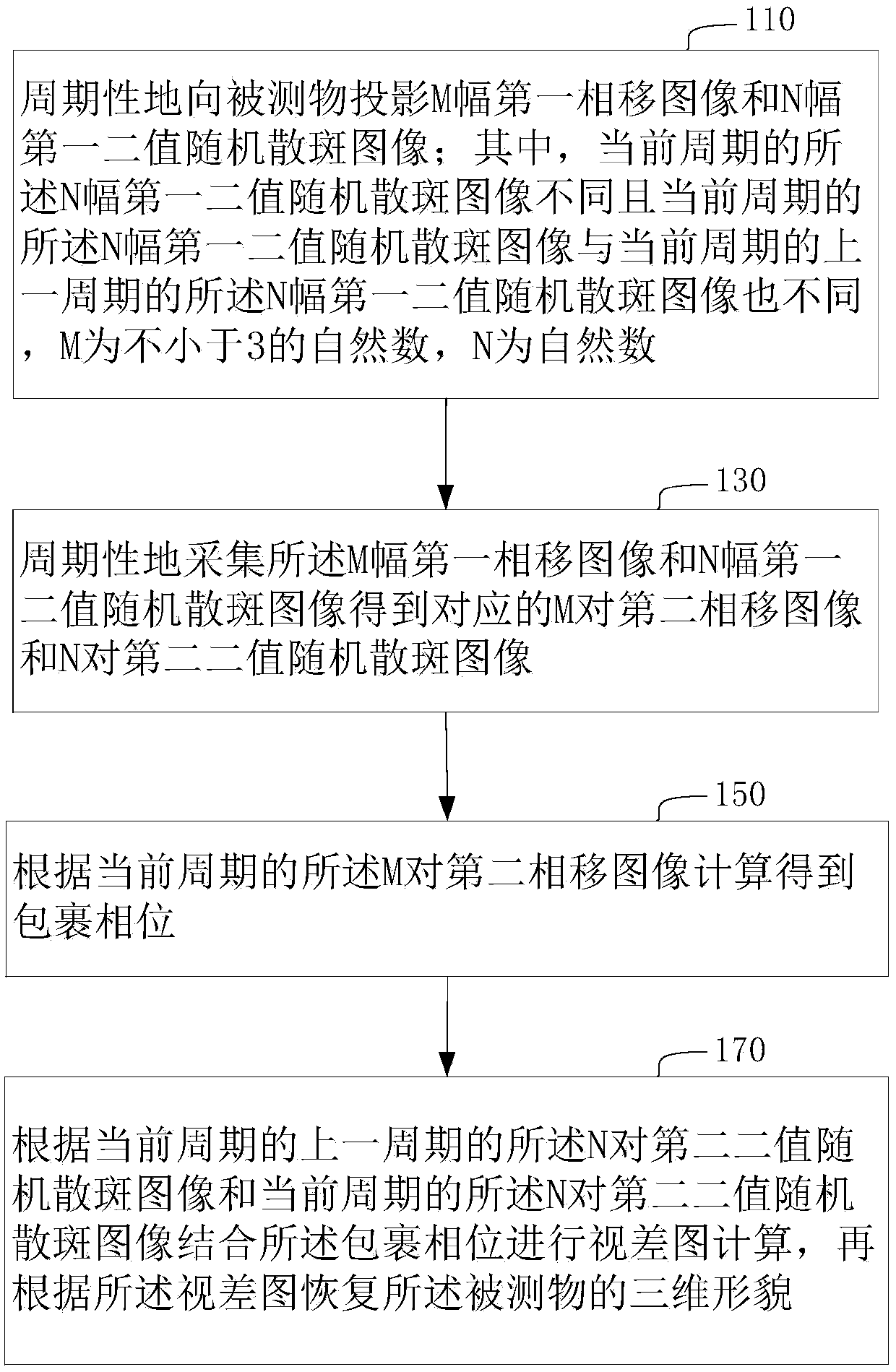

[0055] In view of this, a method for three-dimensional shape measurement is proposed, see figure 1 It is a flow chart of a method for three-dimensional shape measurement in an embodiment, and the method includes:

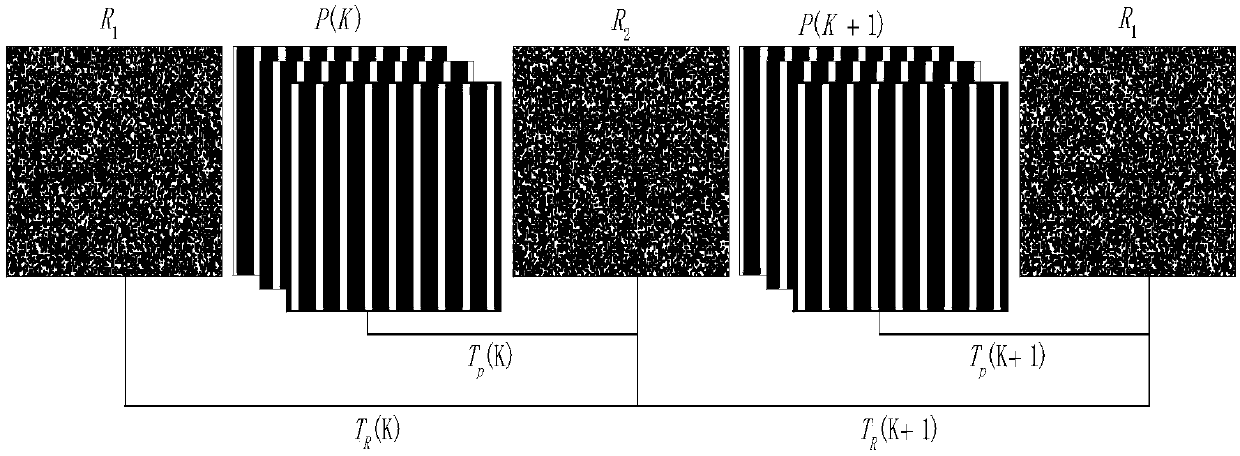

[0056] S110. Periodically project M pieces of first phase shift images and N pieces of first binary random speckle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com