A wind tunnel experimental device for simulating snowfall for low mobility particles

A wind tunnel experiment, low fluidity technology, applied in measurement devices, aerodynamic tests, testing of machine/structural components, etc., can solve problems such as high cost, achieve high simulation fidelity, simple device structure, and stacking height maintain an even effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

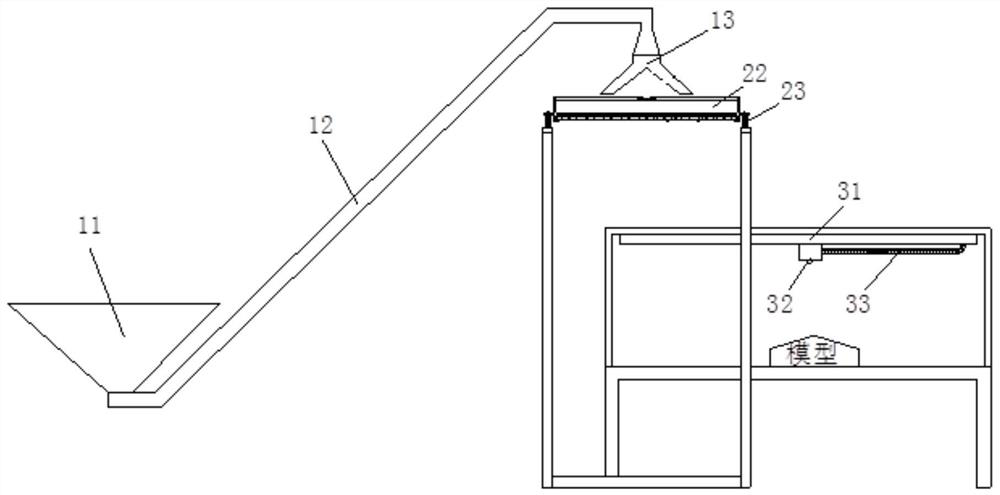

[0024] A wind tunnel experimental device suitable for simulating snowfall with low fluidity particles, its structure can be found in figure 1 shown, including:

[0025] Feeding mechanism: used to transport the particles of simulated snowfall to the powder falling mechanism; the feeding mechanism includes a collection bucket 11, a feed pipe 12 and a distribution pipe 13, wherein the two ends of the feed pipe 12 are respectively connected to the collection bucket 11 and the distribution pipe 13. The material pipe 13 and the material distribution pipe 13 are placed above the powder falling pan 22 and are used to send the particles into the powder falling pan 22 .

[0026] Powder falling mechanism: It is composed of a bracket and a powder falling component arranged on the bracket. The powder falling component includes a powder falling frame, a metal gauze 46 and a soft brush assembly arranged on the powder falling frame, the metal gauze 46 and the powder falling frame It is relat...

Embodiment 2

[0030] On the basis of embodiment 1, this embodiment is further set to:

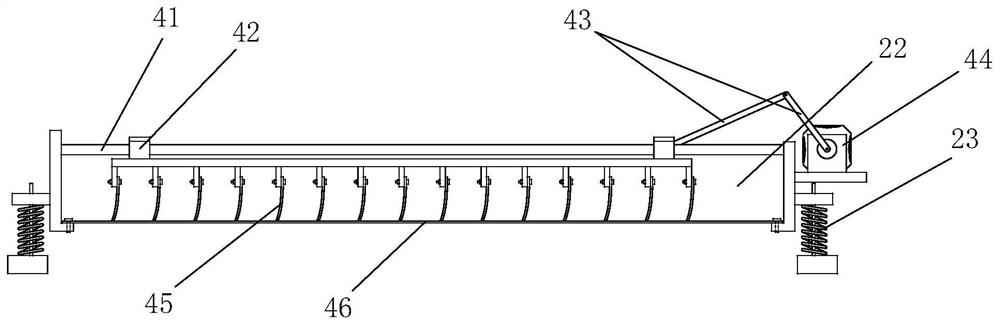

[0031] Such as figure 2 As shown, spring 23 is also installed between the powder falling frame and the support. In this way, the powder dropping mechanism can also generate a certain degree of overall vibration on the spring 23 when the soft brush assembly is tossing, which can help the particles to fall from the gap.

Embodiment 3

[0033] On the basis of embodiment 1, this embodiment is further set to:

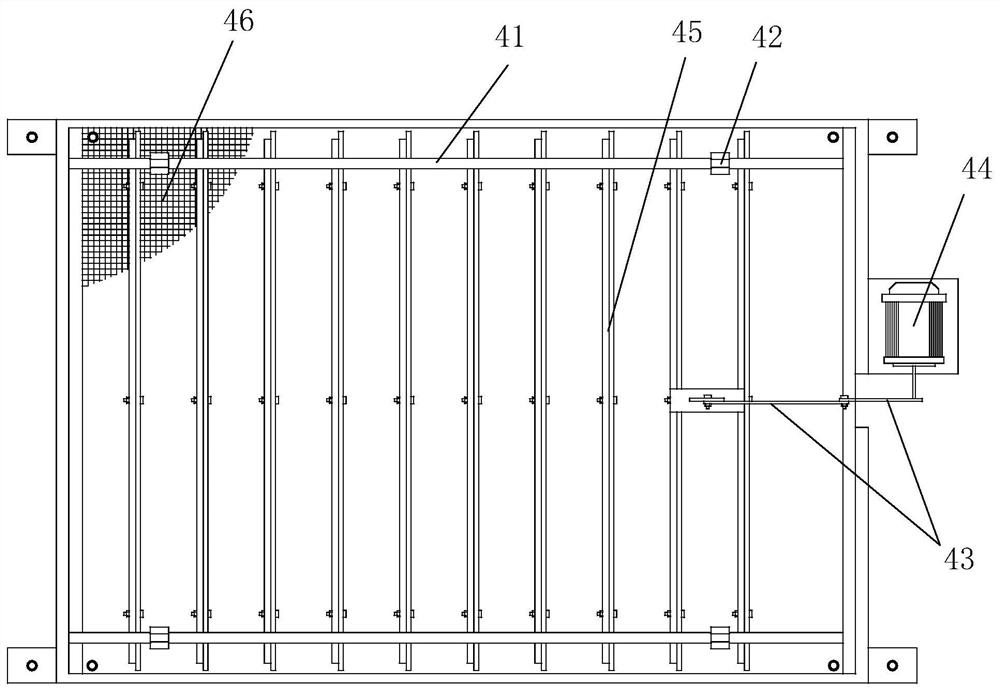

[0034] Such as figure 2 with image 3 As shown, the powder falling frame is also provided with a plastic soft brush that assists the particles to fall. Brush 45 has many groups of bristle parts that are close to metal gauze 46, and guide rail 41 is fixedly arranged on the powder falling frame, and slide block 42 that moves along it is also installed on guide rail 41, and this slide block 42 and plastic soft brush 45 The top is fixedly connected, and the plastic soft brush 45 is driven by the drive motor 55 through the eccentric transmission part 43, and reciprocates on the guide rail 41 by the slider 42, and the bristle part of the plastic soft brush 42 lower surface is attached to the metal gauze 46 upper surface. This situation is mainly suitable for particles with less fluidity. The process of the particles being sent from the feeding mechanism to the powder falling tray 22 and starting to fall is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com