Magnetic flux leakage detection probe

A technology of magnetic flux leakage detection and magnetic circuit, applied in the direction of material magnetic variable, etc., can solve the problem that the sensor probe has not been seen, and achieve the effect of strong defect resolution, stable operation and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following will be further described in conjunction with the accompanying drawings, not to limit the scope of the present invention.

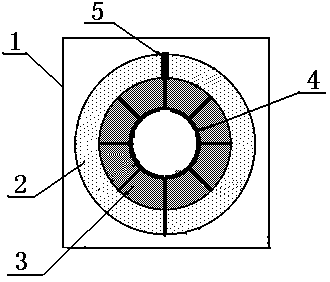

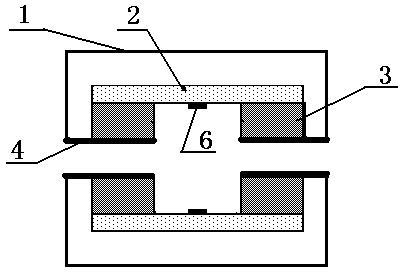

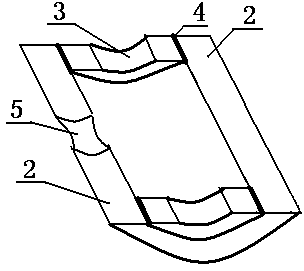

[0022] see Figure 1 to Figure 4 As shown, the present invention includes a housing 1 , a probe and a magnetic circuit structure contained in the housing 1 . The magnetic circuit structure is composed of permanent magnets 3, the permanent magnets 3 are fan-shaped structures, the central angle of the fan-shaped structures is 45°, and the number of the fan-shaped structures is 8 pieces. The magnetic circuit structure is cylindrical, and a cylindrical plastic inner pad 4 is arranged on the inner side of the magnetic circuit structure, and a cylindrical protective layer 2 is arranged on the outer side of the magnetic circuit structure, and the protective layer 2 is made of industrial pure Made of iron. The inner middle part of the protective layer 2 is provided with a circuit board clamping position 6, and a circuit board 7 is fixed on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap