A method for shortening the factory parameter setting time of electric energy meter

A technology for electric energy meters and parameters, which is applied in the field of electric energy meters, can solve problems such as complex protocols, time-consuming, and reduced production efficiency of electric energy meters, and achieve the effects of saving storage space, reducing error probability, and improving the efficiency of factory parameter settings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

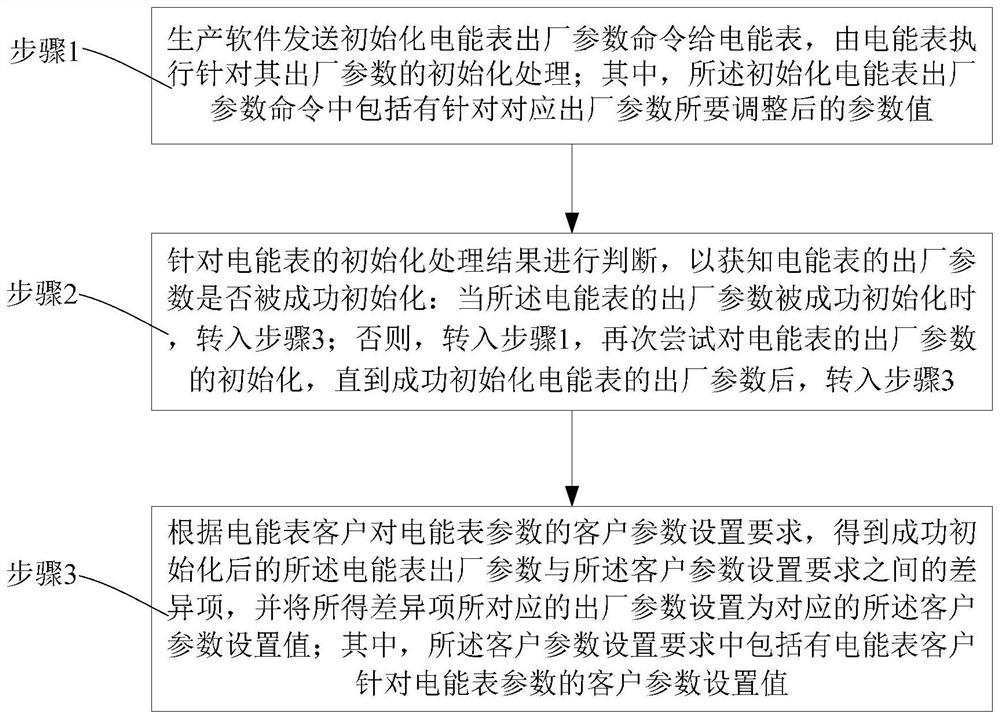

[0037] Such as figure 1 As shown, the method for shortening the factory parameter setting time of the electric energy meter in this embodiment includes the following steps 1 to 3:

[0038] Step 1, the production software sends a command to initialize the factory parameters of the electric energy meter to the electric energy meter, and the electric energy meter performs initialization processing for its factory parameters; wherein, the command for initializing the factory parameter of the electric energy meter includes the parameter values to be adjusted for the corresponding factory parameters; In this embodiment, the command to initialize the factory parameter of the electric energy meter is compatible with supporting the 645 protocol and the 698 protocol command;

[0039] For example, in this embodiment, the factory parameters of the elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com