Method and apparatus for the start-up operation of multi-axis system

A control device and coordinate system technology, applied in general control systems, TV system components, control/adjustment systems, etc., can solve problems such as difficult identification of multi-axis systems and error-prone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

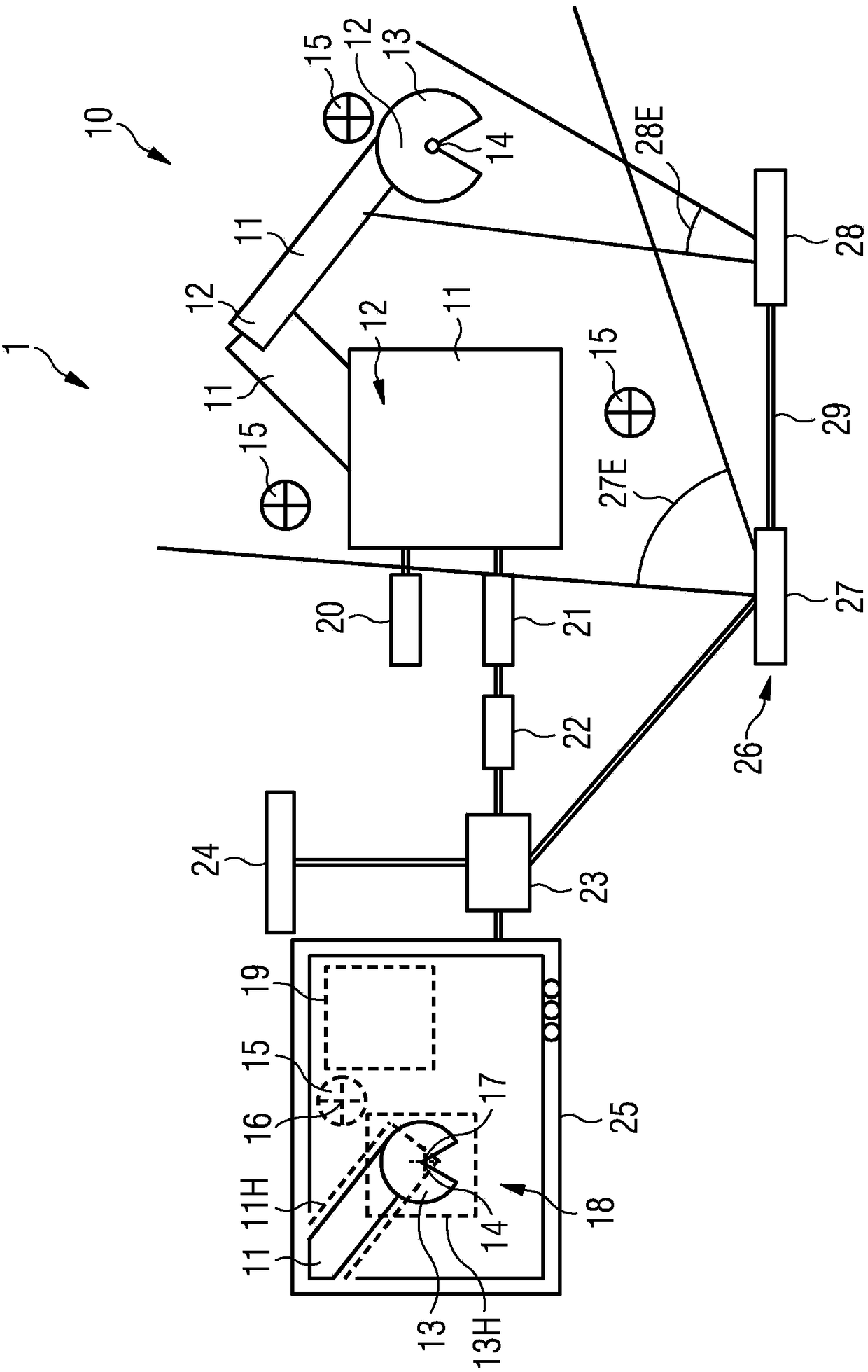

[0029] figure 1 The device 1 according to the invention for starting a multi-axis system 10 is shown schematically. The multi-axis system 10 can be, for example, an industrial robot, a production or packaging machine tool, a CNC milling machine, a shipping crane or the like. However, a multi-axis system can also be understood as a production cell with a number of machines of this type.

[0030] exist figure 1 In the schematic diagram of , the multi-axis system 10 includes a plurality of segments 11 which are connected to each other in pairs via hinges 12 . For example, a tool 13 with a TCP (Tool Center Point) 14 is arranged at the free end of the last section 11 . The tool position of the multi-axis system 10 is described using TCP. The TCP is a reference point located at a suitable location on the tool 13 .

[0031] The movement of the multi-axis system 10 is controlled by a control device 20 . Control means, such as a programmable logic controller (SPS), may be provide...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap