Aquatic abalone feed processing device

A feed processing and abalone technology, which is applied to feed, raw material extrusion granulation, grain processing and other directions, can solve the problems of low crushing efficiency and unsatisfactory crushing effect, and achieve the effects of convenient operation, reasonable design and structure, and improved quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

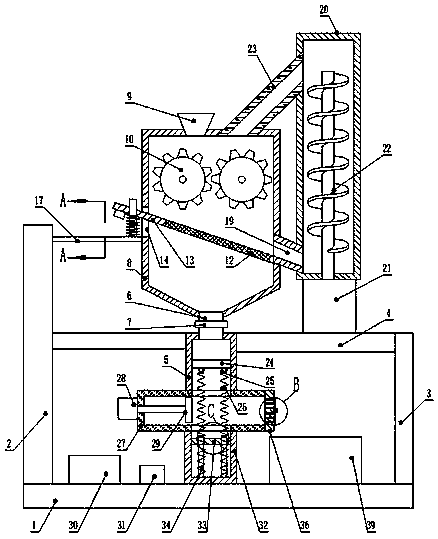

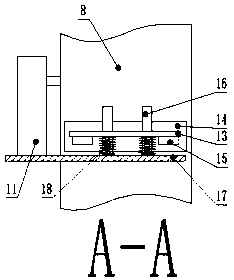

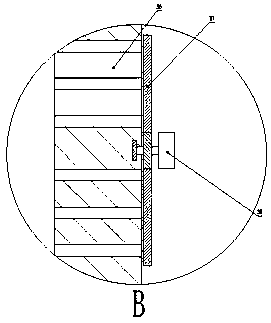

[0020] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0021] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a kind of aquatic abalone feed processing device comprises a base 1, and the top of the base 1 is fixedly provided with a support positioning plate A2 and a support positioning plate B3, and the top of the support positioning plate A2 is fixedly connected with a fixed support plate 17, the The other end of the fixed support plate 17 is fixedly connected with a crushing box 8, the top of the crushing box 8 is fixedly provided with a feed nozzle 9, and the crushing box 8 is provided with two crushing rollers 10, two crushing rollers 10 Pass through the crushing box 8 through the connecting rod and be fixedly connected with the output end of the motor 11. The motor 11 is fixedly arranged on the top of the fixed support plate 17, and a screen 12 is obliquely arranged i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com