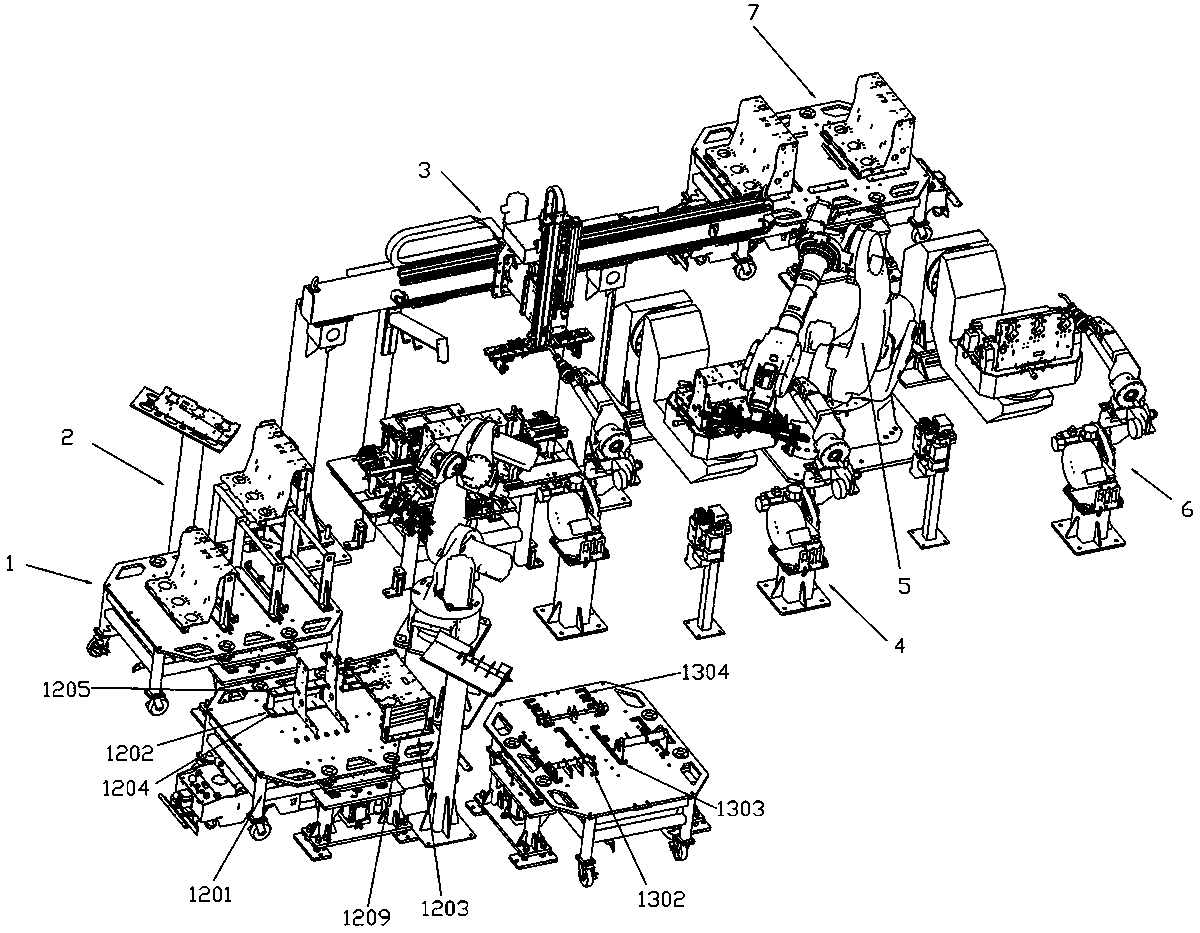

Assembly and welding automatic production line for circuit breaker robot

An automatic production line, assembly welding technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of low efficiency of circuit breaker assembly and welding, reduce manual participation, reduce labor intensity, and improve efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

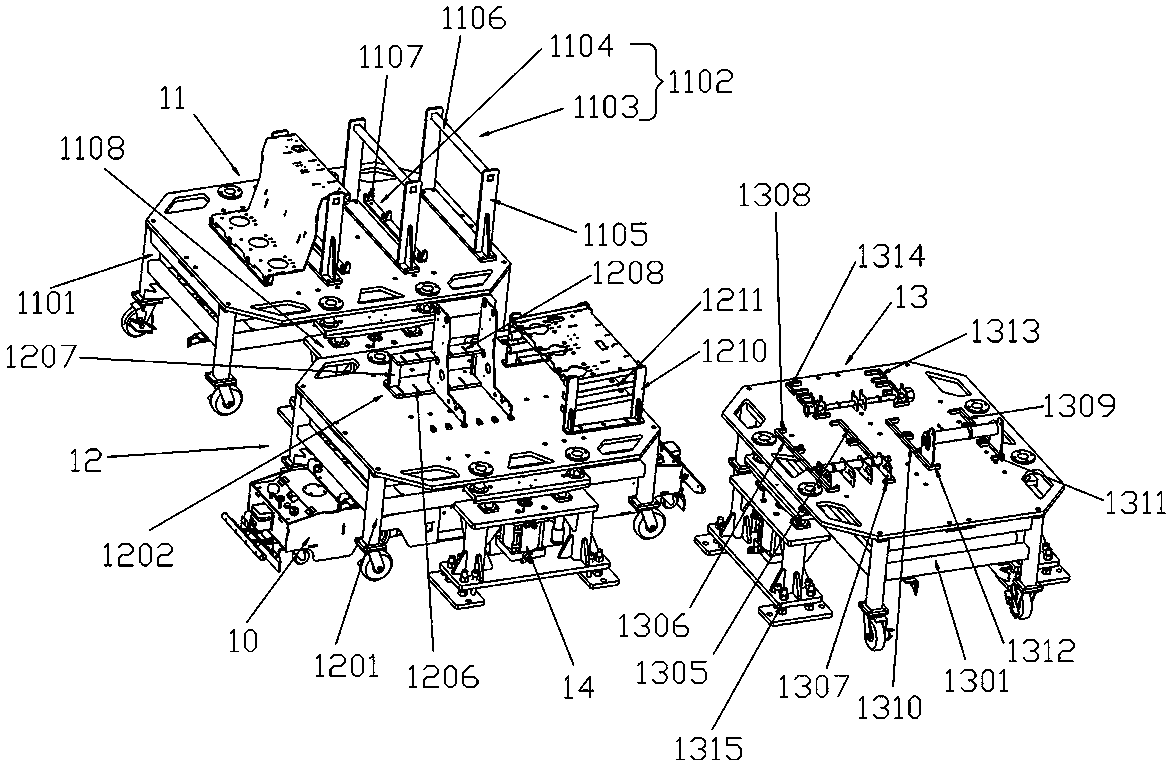

Method used

Image

Examples

Embodiment 2

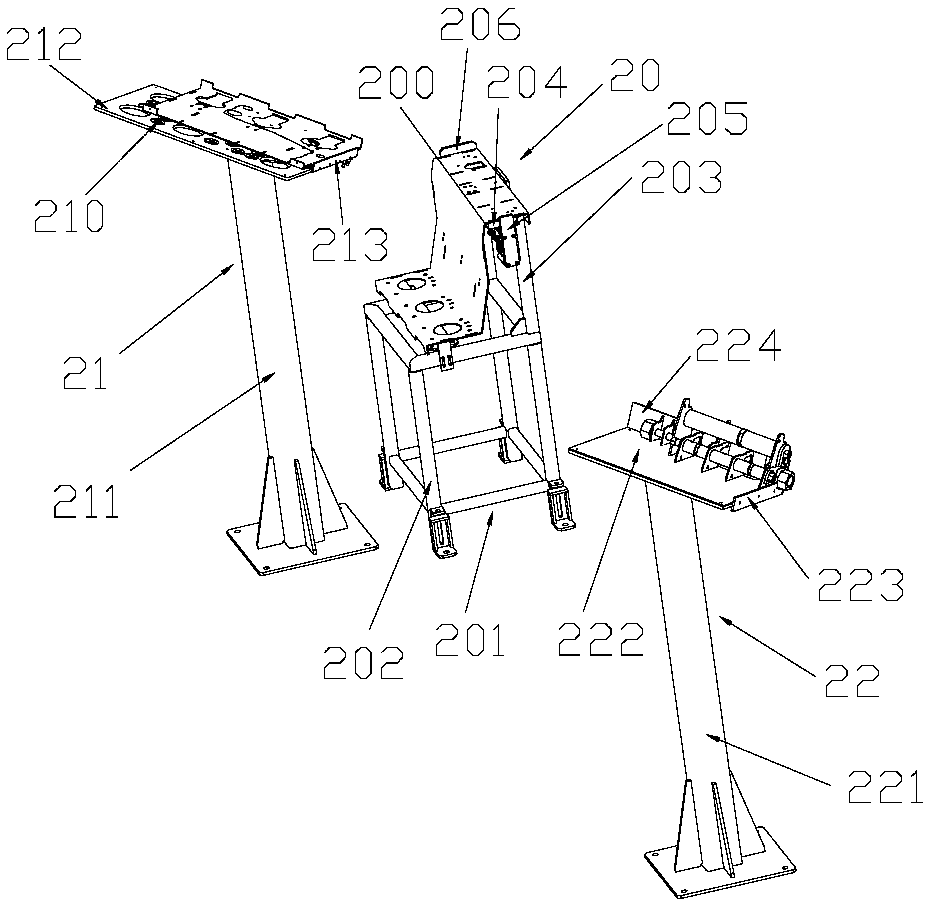

[0048] This embodiment is a further improvement on the basis of the first embodiment. Compared with the first embodiment, the robot assembly spot welding device 3 described in this embodiment further includes a 3D vision system 34, and the 3D vision system 34 includes A 3D vision support column 340 and a connecting rod 341 arranged on the 3D vision support column 340, and a monitoring probe 342 is arranged on the connecting rod 341. The rest of the mechanism of this application is the same as the first embodiment. For details, please refer to the first embodiment, which will not be repeated in this embodiment. In this embodiment, when the rear bending plate is installed, the 3D vision system 34 detects whether the rear bending plate is installed in place. If it is not correctly assembled, the assembly station alarms, the device enters the safe mode, and manual intervention in the assembly work until the assembly work is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com