Manufacturing device and preparation method of a plug-free light-transmitting concrete slab

A light-transmitting concrete and device-making technology, which is applied in the field of building materials, can solve the problems of manual insertion of optical fibers, low efficiency of optical fiber arrangement, and heavy workload, and achieve the effects of simple overall device, simple and quick demoulding of the device, and saving concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with embodiment.

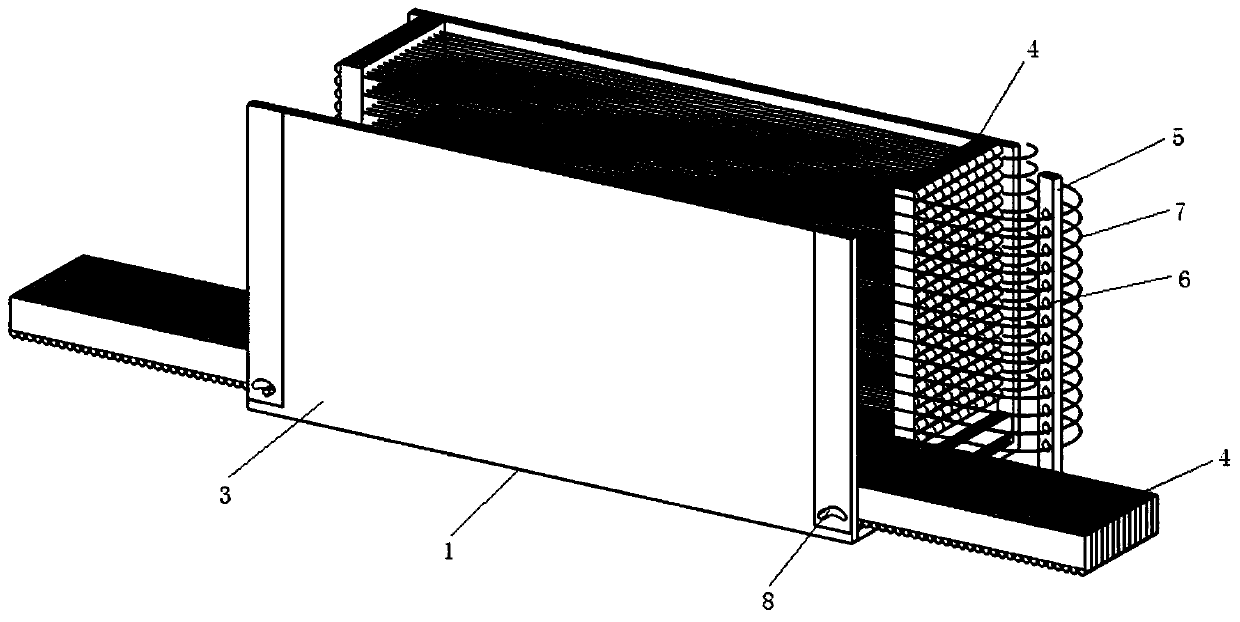

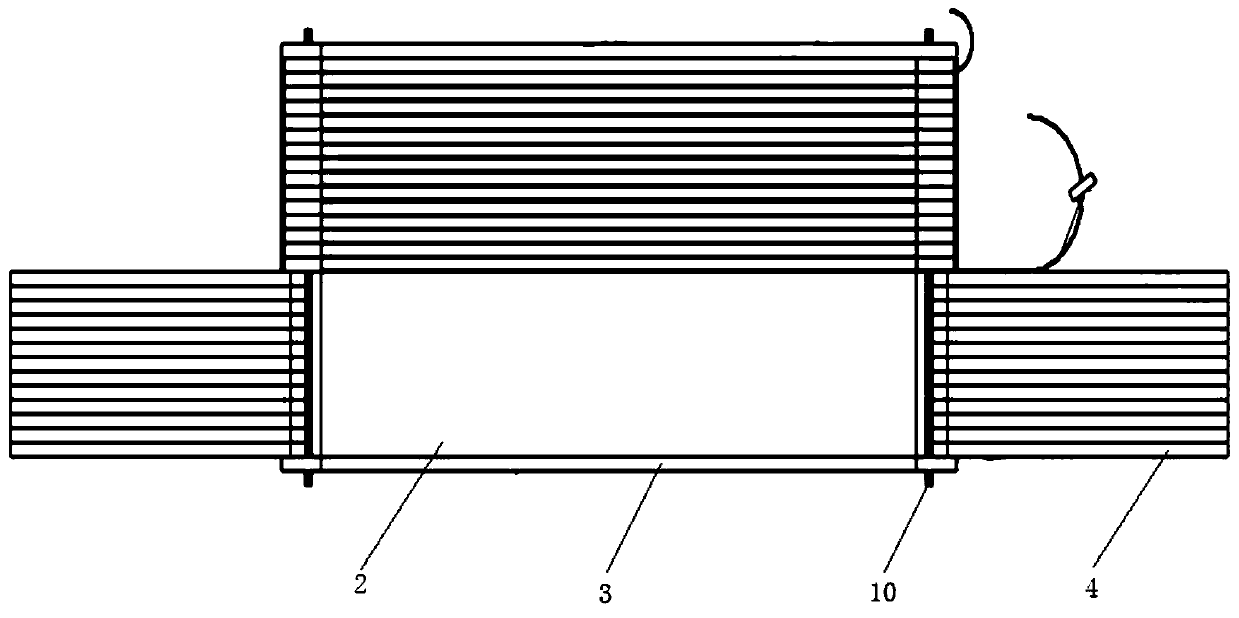

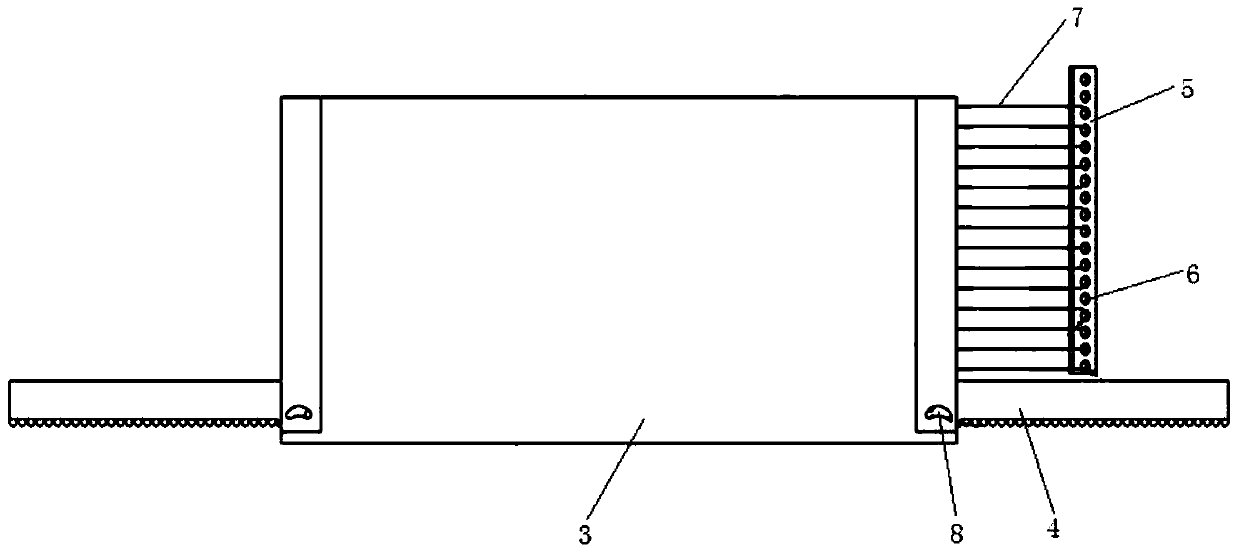

[0037] according to Figure 1 to Figure 4 As shown, the present invention provides a manufacturing device for a plug-free light-transmitting concrete slab, comprising: a U-shaped support box 1 placed vertically, and the U-shaped support box 1 includes a bottom plate 2 and two side plates 3 , the cross-sections of the bottom plate 2 and the side plate 3 are rectangular, and the two side plates 3 are arranged in parallel and opposite to each other, and are vertically connected with the bottom plate 2 respectively, and the ends of the two side plates 3 form two open ends in the transverse direction, A plurality of splints 4 are arranged at the open end, and a plurality of splints 4 are arranged longitudinally at the open end to close the open end, and the splint 4 can rotate relative to the bottom plate 2, so that the The open end is closed or open. When the open end is close...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com