Wheel using three-dimensional quasi photonic crystals to reduce vibration and noise

A phononic crystal, vibration reduction and noise reduction technology, applied in the direction of wheels, wheels characterized by rail running parts, vehicle parts, etc., can solve the problems of complex manufacturing process and insufficient safety, and achieve simple manufacturing process and high safety performance, the effect of suppressing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

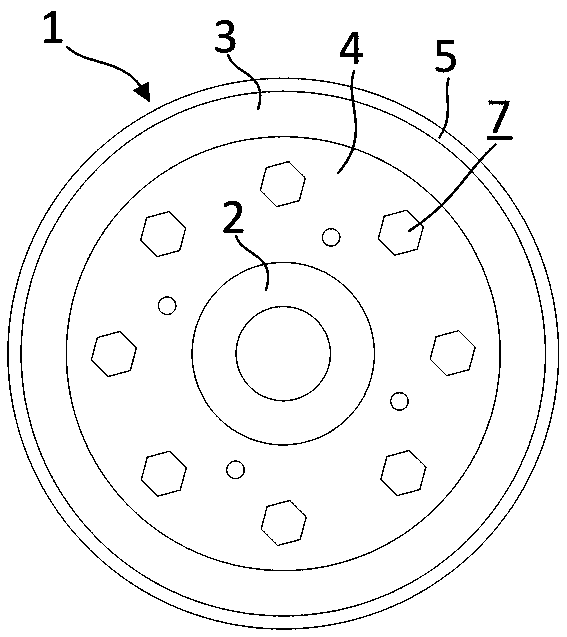

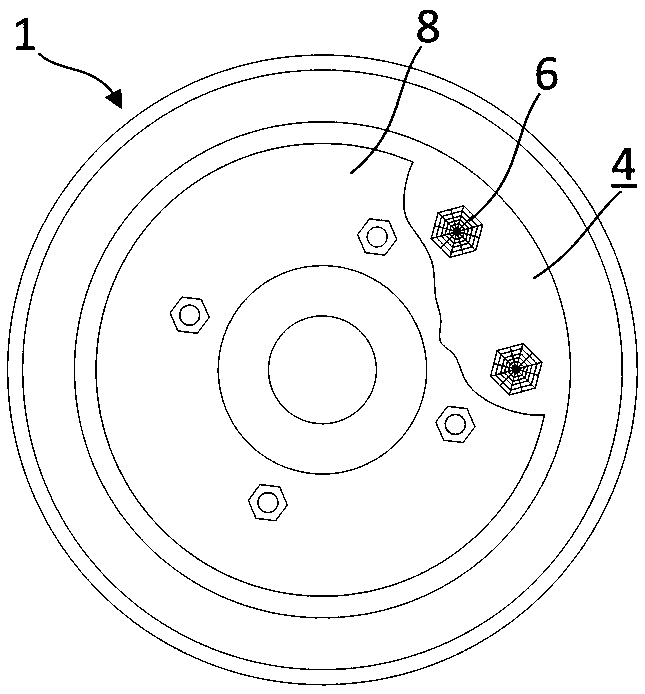

[0022] Embodiment 1: as figure 1 , 2 As shown, this embodiment specifically relates to a wheel that utilizes a three-dimensional quasi-phonon crystal for vibration and noise reduction. The wheel 1 includes a hub 2, a rim 3, and a web 4; between; the outer edge of the rim 3 is a tread, and the edge of the tread is provided with a raised rim 5; and eight three-dimensional quasi-phononic crystals 6 are arranged on the outer surface of the web 4.

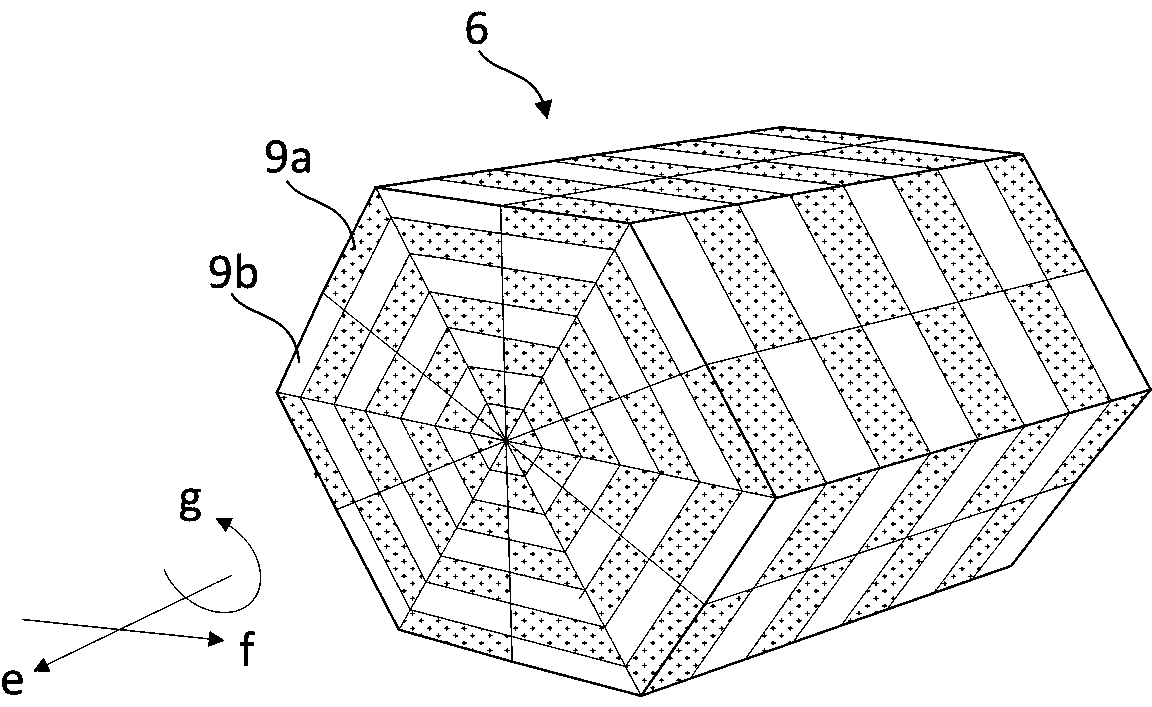

[0023] Such as figure 1 , 2 As shown, the three-dimensional quasi-phononic crystal 6 is in the shape of a hexagonal prism, and eight holes 7 matching the three-dimensional quasi-phononic crystal 6 are provided on the outer surface of the web 4; the holes 7 do not pass through the web 4, and each A three-dimensional quasi-phononic crystal 6 is inserted in a hole 7; a cover plate 8 is also provided on the outer surface of the web 4, and the cover plate 8 is fixedly connected with the web 4 by bolts; one end of the three-dimensional qua...

Embodiment 2

[0028] Embodiment 2: as Figures 1 to 3 As shown, in this embodiment, the arrangement of the first phononic crystal unit 9 a and the second phononic crystal unit 9 b is the same as that in Embodiment 1; the difference between the two lies in the structure of the phononic crystal unit 9 .

[0029] In this embodiment, the first phononic crystal unit 9a includes a piezoelectric ceramic core material and a metal film disposed on the surface of the piezoelectric ceramic core material; the metal film is a pure copper film, and the metal film is prepared on the piezoelectric ceramics The surface of the core material; when the elastic wave propagates to the first phononic crystal unit 9a, the piezoelectric ceramic core material will vibrate under the action of the elastic wave, and convert part of the vibration energy into electrical energy, which is arranged on the surface of the piezoelectric ceramic core material The metal film on the surface of the piezoelectric ceramic can immedi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com