Pneumatic tire with improved durability

A technology for pneumatic tires and tires, which is applied to the reinforcement layer of pneumatic tires, tire parts, tire edges, etc., which can solve the problems of poor control of the width and thickness of the film, poor adhesion performance and unstable durability of the film, and achieve Effects of improving durability, saving costs, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

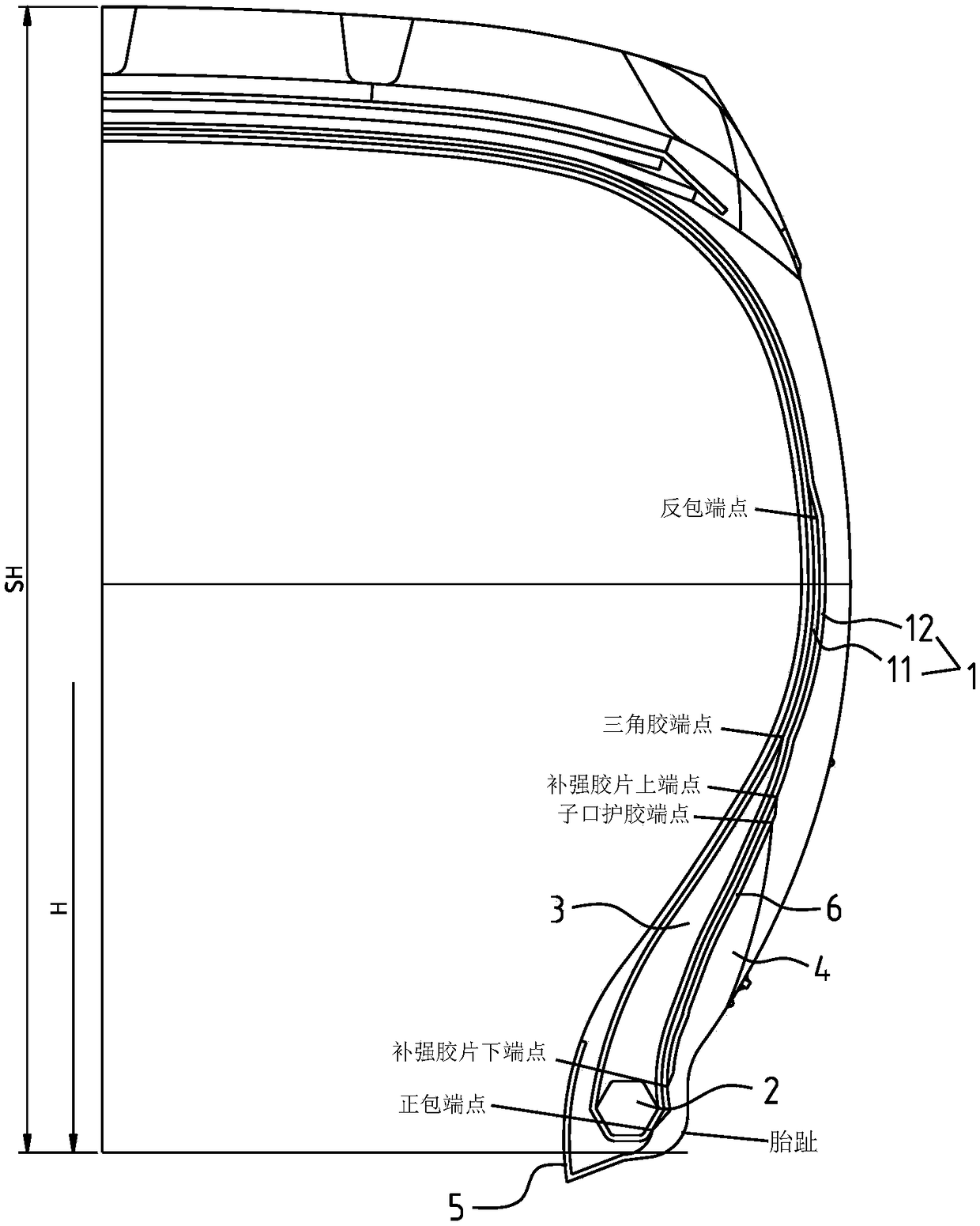

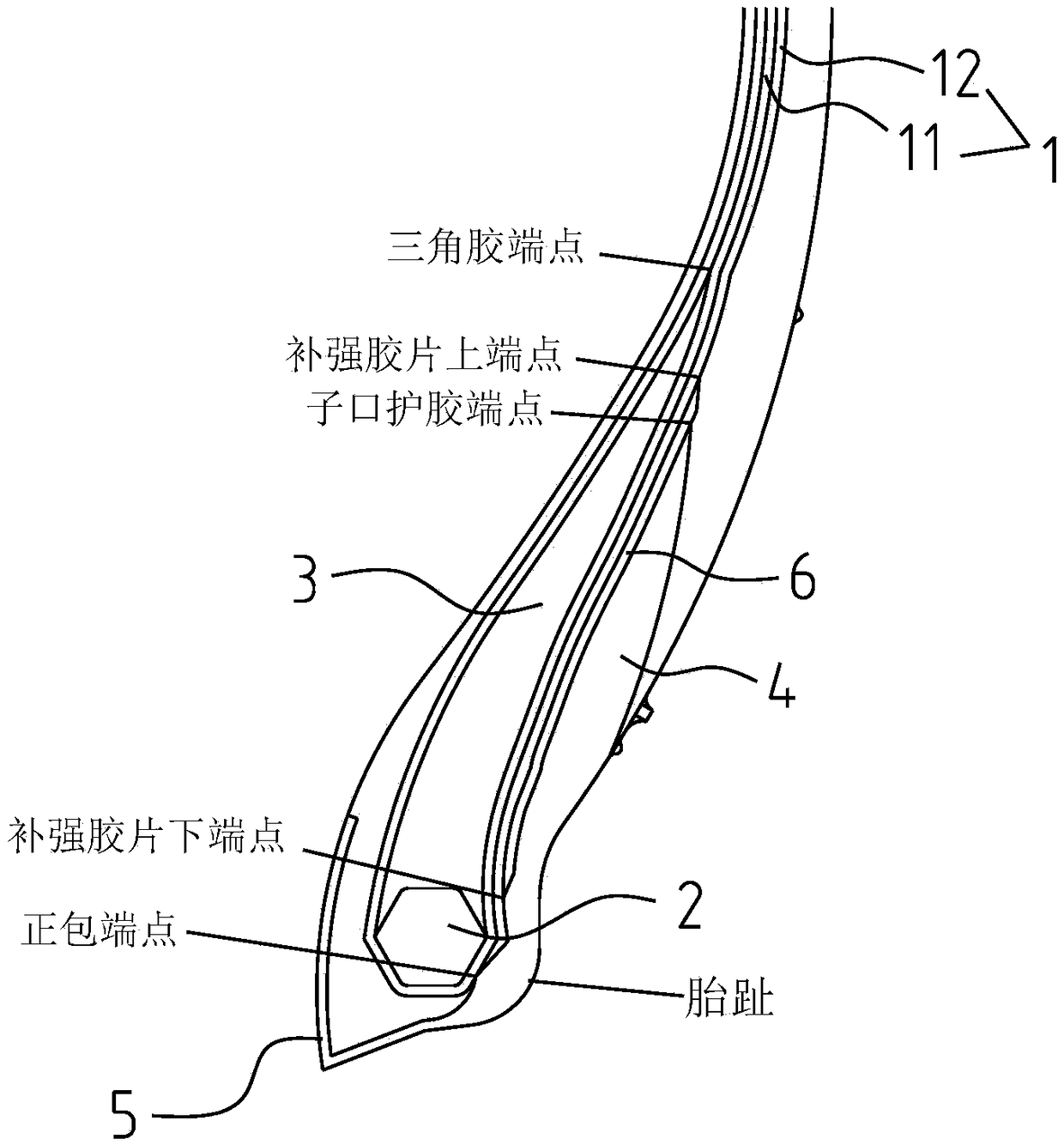

[0022] The pneumatic tire includes a carcass 1, a bead core 2, an apex rubber 3, a slit protective rubber 4 and an anti-friction layer 5 for wrapping the bottom of the slit, and the carcass includes a first carcass ply 11 and The second carcass ply 12 .

[0023] The first carcass ply 11 is turned up around the bead core and the apex from the inner side in the tire axial direction toward the outer side in the tire axial direction, and the second carcass ply 12 is turned up along the bead The core and the apex extend downward from the outer side in the tire axial direction. The height of the turnup endpoint of the first carcass ply 11 is (0.45-0.55) SH, and the turnup endpoint of the second carcass ply 12 is located within 3 mm above and below the bead toe position.

[0024] A reinforcing film 6 extending radially along the tire is arranged between the second carcass ply 12 and the rim protection rubber 4, and the vertical height from the lower end point of the reinforcing film...

Embodiment 2

[0026] The difference from Embodiment 1 is that the outer end point of the anti-friction layer 5 in the tire axial direction is located at the front end point of the second carcass ply.

Embodiment 3

[0028] The difference from Example 1 is that the heights of the apex 3 and the rim protector 4 are different. If H≤143.5mm, the height of the apex is 45mm, and the height of the rim protector is 40mm; if H>143.5mm, the triangle The height of the glue is 55mm, and the height of the mouth protection glue is 40mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com