Material taking device and pile material taking method

A technology of reclaiming device and stockpile, which is applied in the direction of packaging, loading/unloading, transportation and packaging, etc., which can solve the problems of wasting manpower, large rake size, and inability to completely fill the stockyard, so as to reduce production capacity Fluctuation and operating vibrations, improved carding effect, good loosening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. In addition, those skilled in the art can make corresponding combinations of features in the embodiments in this document and in different embodiments according to the descriptions in this document.

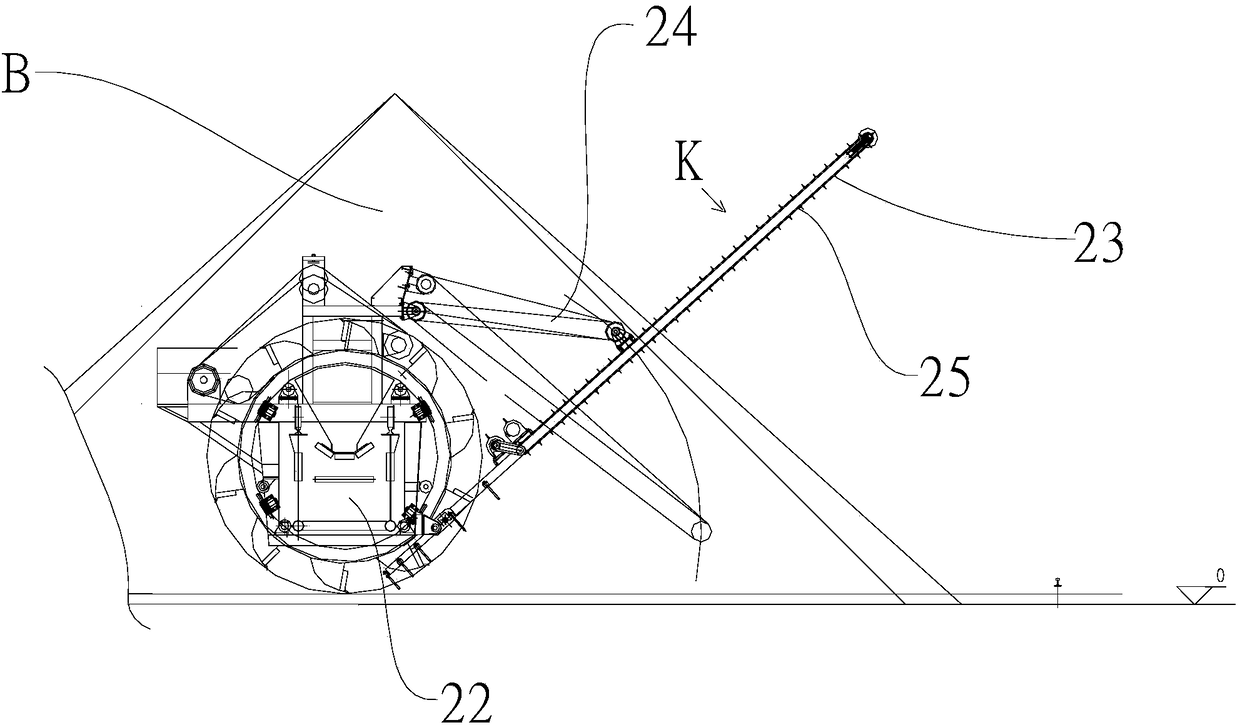

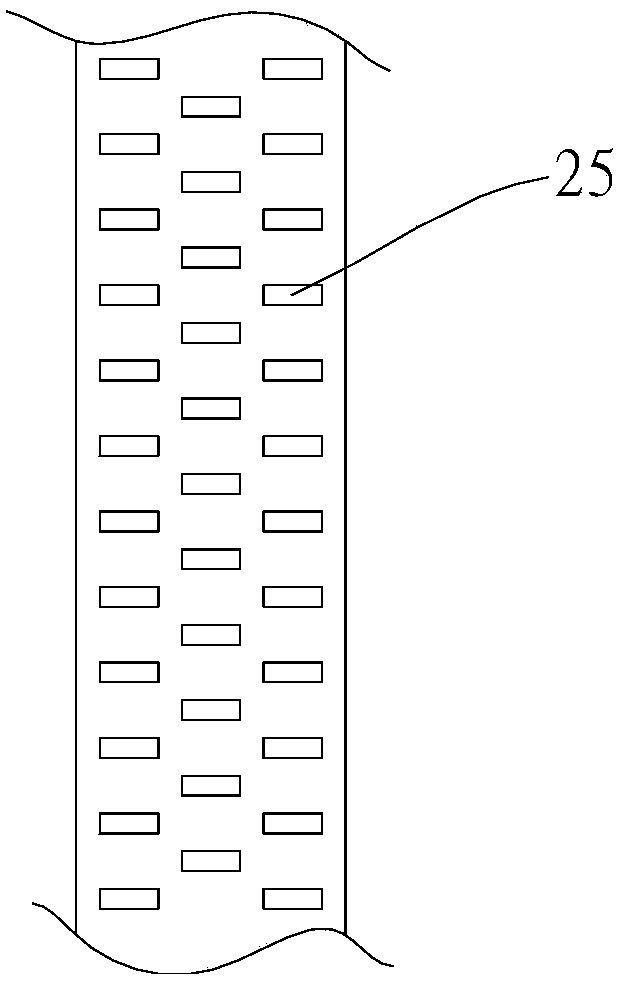

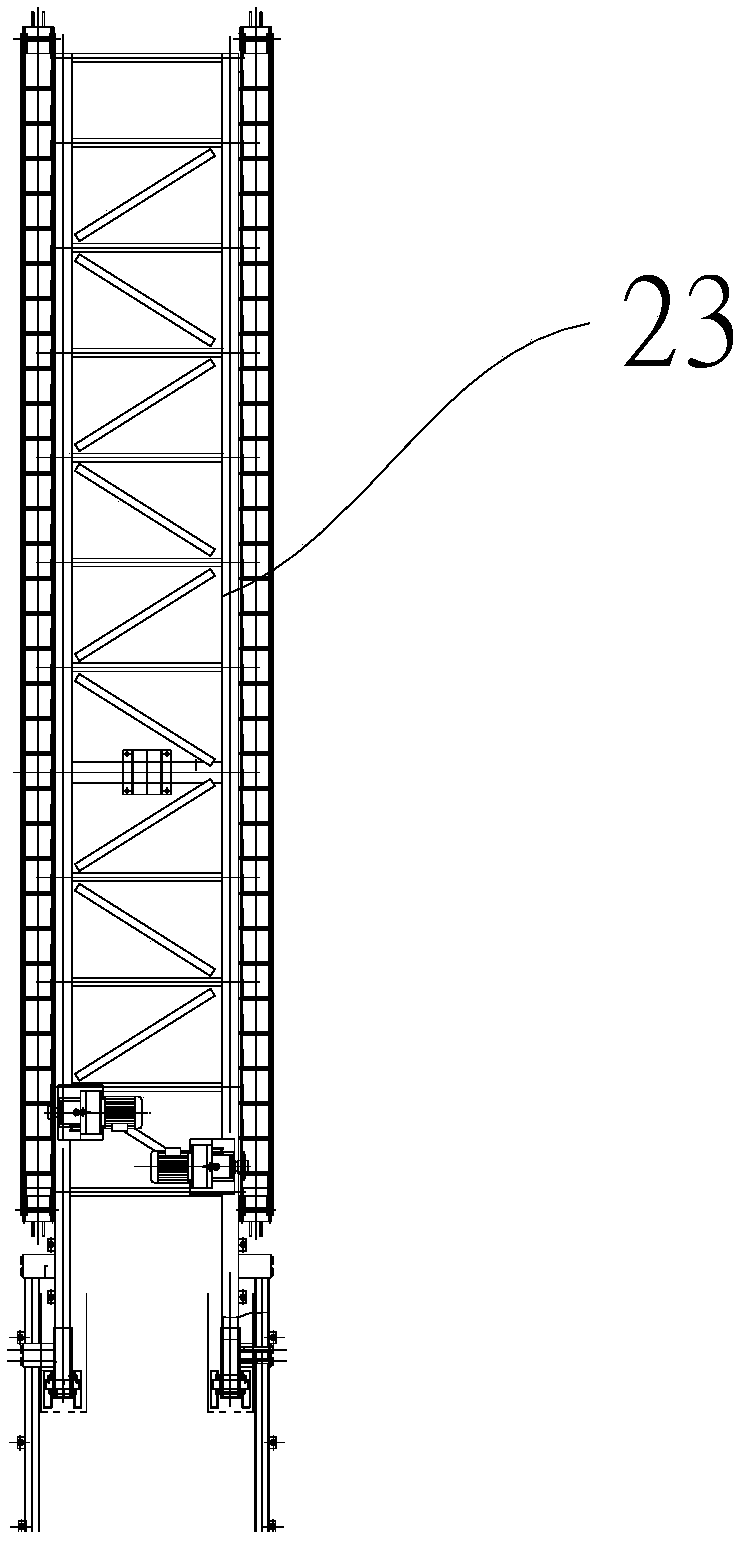

[0057] Embodiments of the present invention are as follows, with reference to Figure 1~3 , a material retrieving device, at least including a frame 22 and a combing device, one end of the combing device is connected with the frame 22 through a connecting mechanism, and the combing device includes a combing frame 23 and is arranged on the combing device The main material rake on the frame 23, the main material rake includes several main material combs 25, and the main material combs 25 are distributed in multiple rows al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com