An ultra-deep vertical shaft large-load spiral winding friction lifting system and method

A helical winding and frictional lifting technology, which is applied to lifting equipment, transportation and packaging in mines, can solve problems such as large fluctuations in stress values, large fluctuations in static stress values, and excessive terminal loads.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

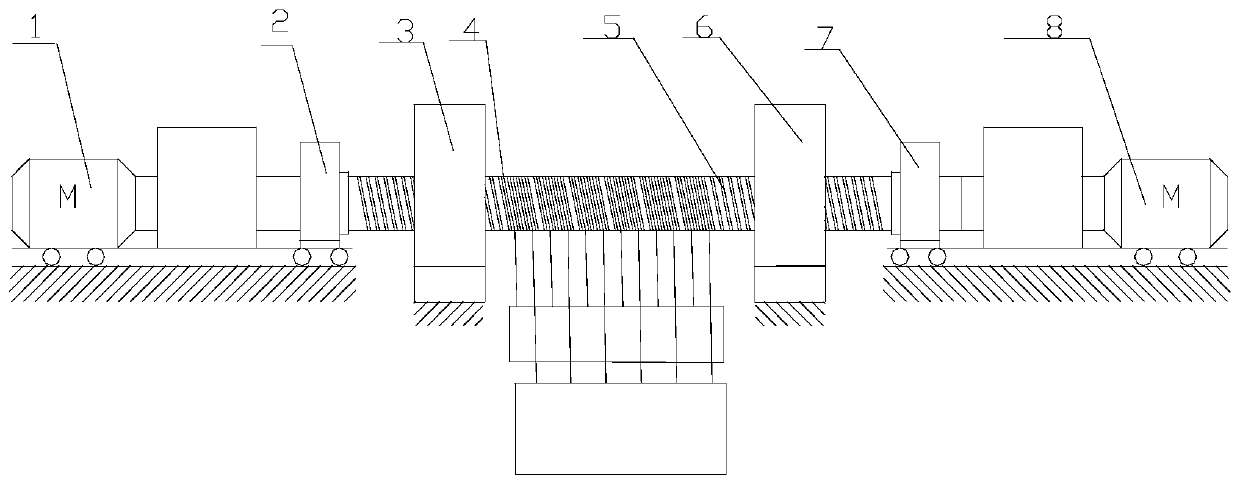

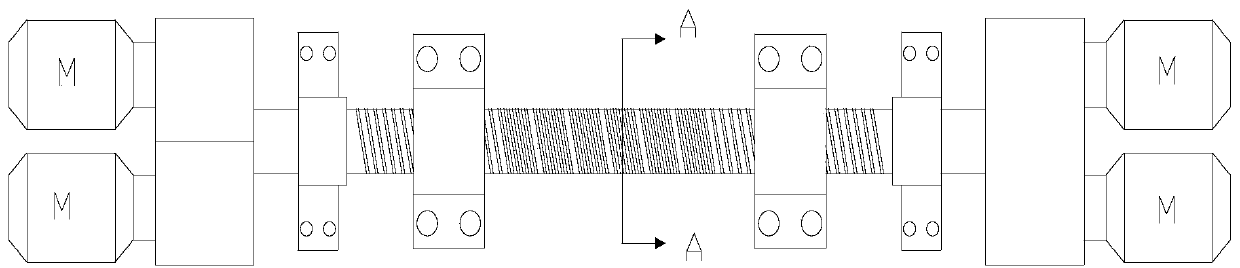

[0036] Using the above-mentioned super-deep vertical shaft heavy load spiral friction lifting method based on the combination of winding and friction lifting:

[0037] When lifting, the two motor units start synchronously, one forward and the other reverse;

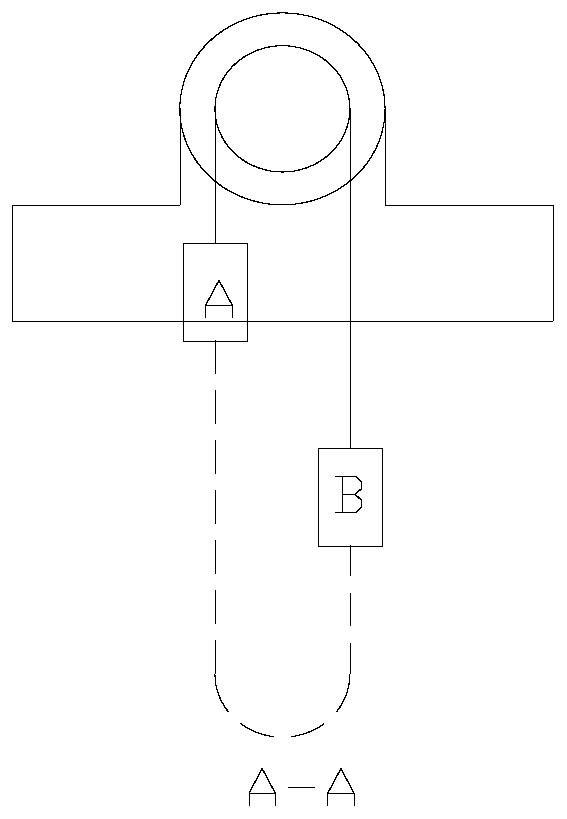

[0038]When the motor unit A1 reverses (clockwise) and the motor unit B8 rotates forward, the output shafts of the two motor units drive the spiral friction roller 5 to rotate through the coupling, and the spiral friction roller 5 rotates along the transmission with the spiral groove The axis of the supporting bearing seat A3 and the transmission supporting bearing seat B6 with spiral groove moves to the right, and the friction force between the hoisting wire rope 4 wound on the spiral friction drum 5 and the spiral friction drum 5 will move along the groove of the spiral friction drum 5. The groove moves leftwards with respect to the spiral friction drum 5, which just offsets the horizontal displacement of the spiral fric...

Embodiment 2

[0040] Using the above-mentioned super-deep vertical shaft heavy load spiral friction lifting method based on the combination of winding and friction lifting:

[0041] When lifting, the two motor units start synchronously, one forward and the other reverse;

[0042] When the motor unit A1 rotates forward (counterclockwise) and the motor unit B8 reverses, the output shafts of the motor unit A1 and the motor unit B8 drive the spiral friction roller 5 to rotate through the coupling, and the spiral friction roller 5 rotates along the spiral The axis of the transmission support bearing seat A3 with the groove and the transmission support bearing seat B6 with the spiral groove moves to the left, and the friction force between the hoisting wire rope 4 wrapped on the spiral friction drum 5 and the spiral friction drum 5 will move along the spiral friction drum. The groove of 5 is winding and rising to the right relative to the spiral friction drum 5, which just offsets the horizontal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com