Prefabricated part hoisting device and method based on internet of things and Beidou positioning technology

A prefabricated component and Beidou positioning technology, which is applied to electrical components, transportation and packaging, and load hanging components, can solve the problems of lack of high precision, low efficiency, and lack of real-time information in the hoisting process of prefabricated components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

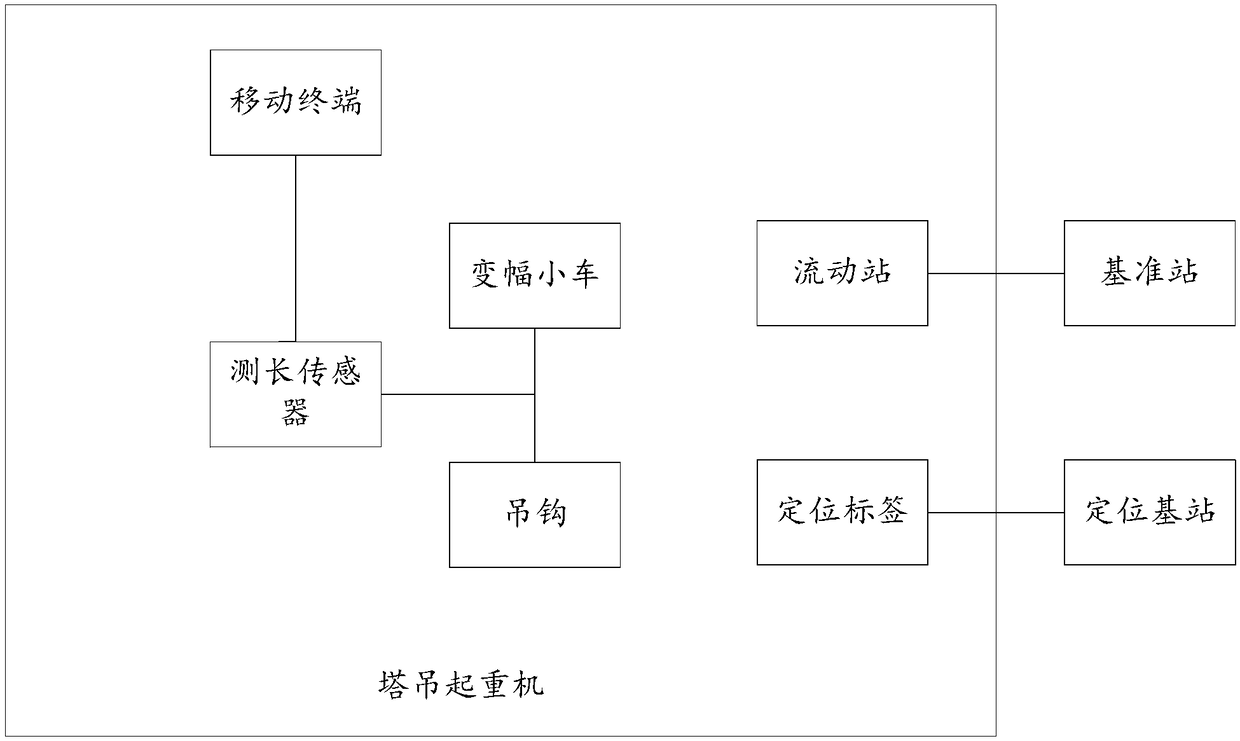

[0032] Such as figure 1 As shown, in this embodiment, a prefabricated component hoisting device based on the Internet of Things and Beidou positioning technology includes: a reference station, a rover, a length measurement sensor, a positioning base station, a positioning tag, a mobile terminal, a tower crane, and a luffing The trolley and the hook, the positioning label is set on the prefabricated component, and the positioning is performed by positioning the positioning base station, the base station is fixed at the preset coordinate point, and the mobile terminal is set in the cab of the tower crane. The luffing trolley is set on the boom of the tower crane, the mobile station is set on the luffing trolley, and moves synchronously with the luffing trolley, and the length measuring sensor is used to measure the distance between the hook and the luffing trolley. elevation difference.

[0033] In this embodiment, the precise positioning and precise hoisting of the prefabricat...

Embodiment 2

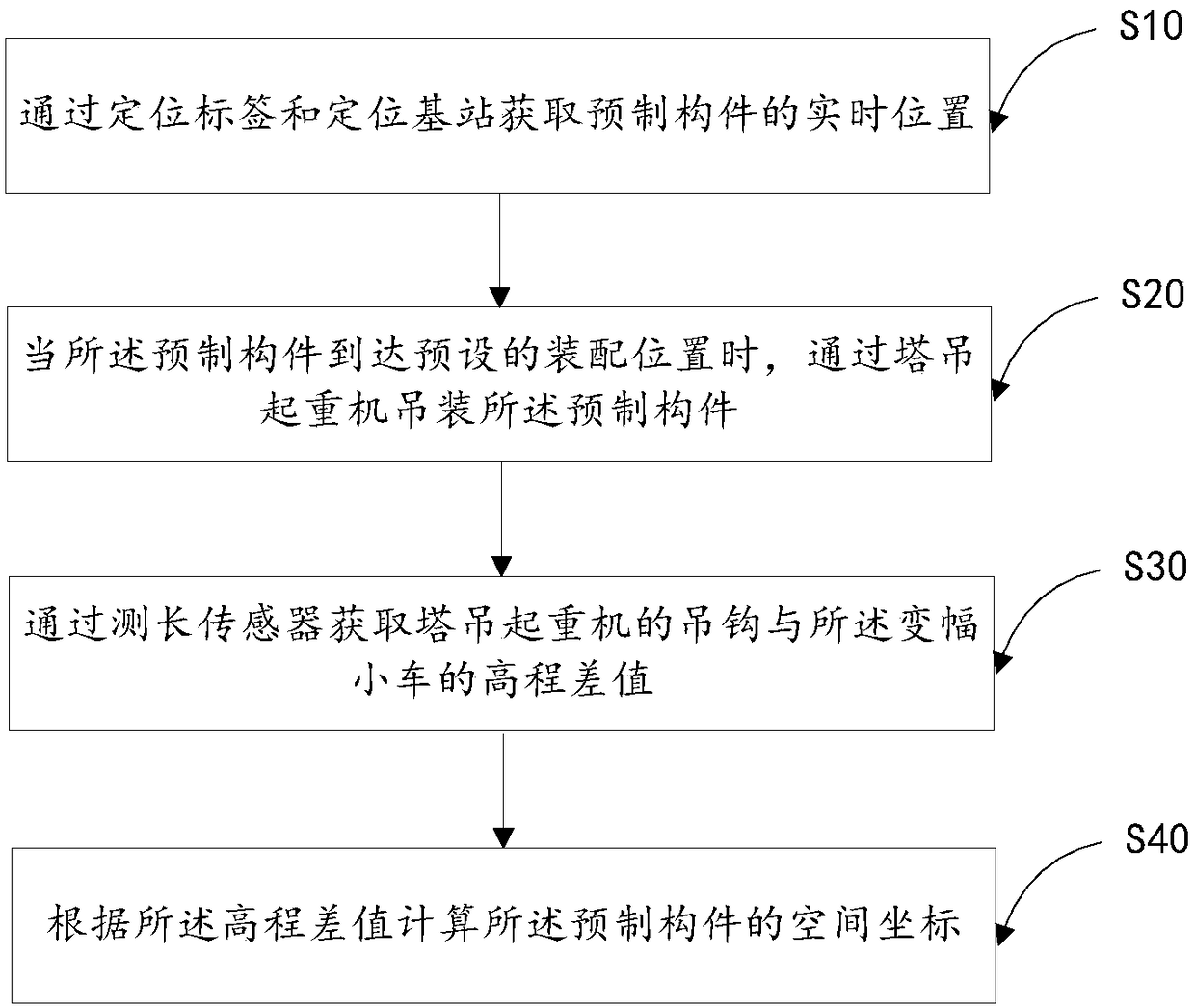

[0046] like image 3 As shown, in this embodiment, a prefabricated component hoisting method based on the Internet of Things and Beidou positioning technology includes:

[0047] S10. Obtain the real-time position of the prefabricated component through the positioning tag and the positioning base station;

[0048] S20. When the prefabricated component reaches a preset assembly position, hoist the prefabricated component by a tower crane; the boom of the tower crane is provided with a luffing trolley;

[0049] S30. Obtain the elevation difference between the hook of the tower crane and the luffing trolley through the length measuring sensor;

[0050] S40. Calculate the spatial coordinates of the prefabricated component according to the elevation difference.

[0051] In this embodiment, the precise positioning and precise hoisting of the prefabricated components are realized through the positioning technology, which improves the production efficiency.

[0052] In this embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com