Preparation method of porous conical ZnO nano-powder

A nano-powder and conical-shaped technology, which is applied in the field of nano-material preparation, can solve the problems that the product does not have porous structure characteristics, the conical nano-ZnO synthesis process is complicated, and the cost is high, so as to achieve good photocatalytic performance and good monodispersity , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0025] Example 1

[0026] A preparation method of porous conical ZnO nano powder includes the following steps:

[0027] (1) Dissolve 0.02634 g of anhydrous zinc acetate in a mixed solvent consisting of 30 mL of absolute ethanol and 0.5 mL of deionized water to obtain a zinc acetate solution;

[0028] (2) The zinc acetate solution obtained in step (1) is heated to 70° C. under magnetic stirring and kept for 15 minutes to obtain a solid-liquid mixture containing ZnO precipitation;

[0029] (3) The solid-liquid mixture containing ZnO precipitate obtained in step (2) is centrifuged and washed with absolute ethanol for 5 times, and then the centrifuged-washed product is dried at 50° C. for 12 hours to obtain porous conical ZnO nanopowder.

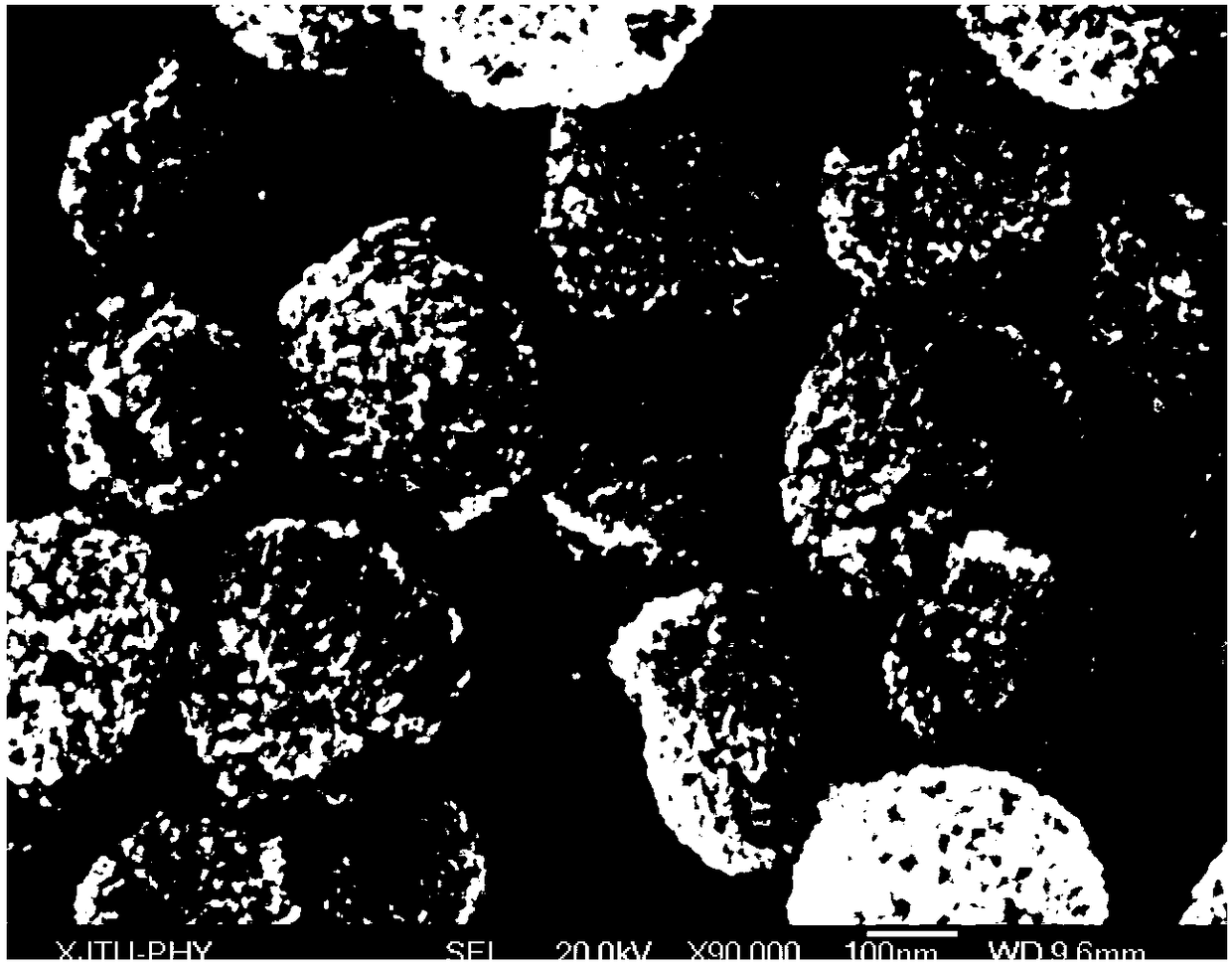

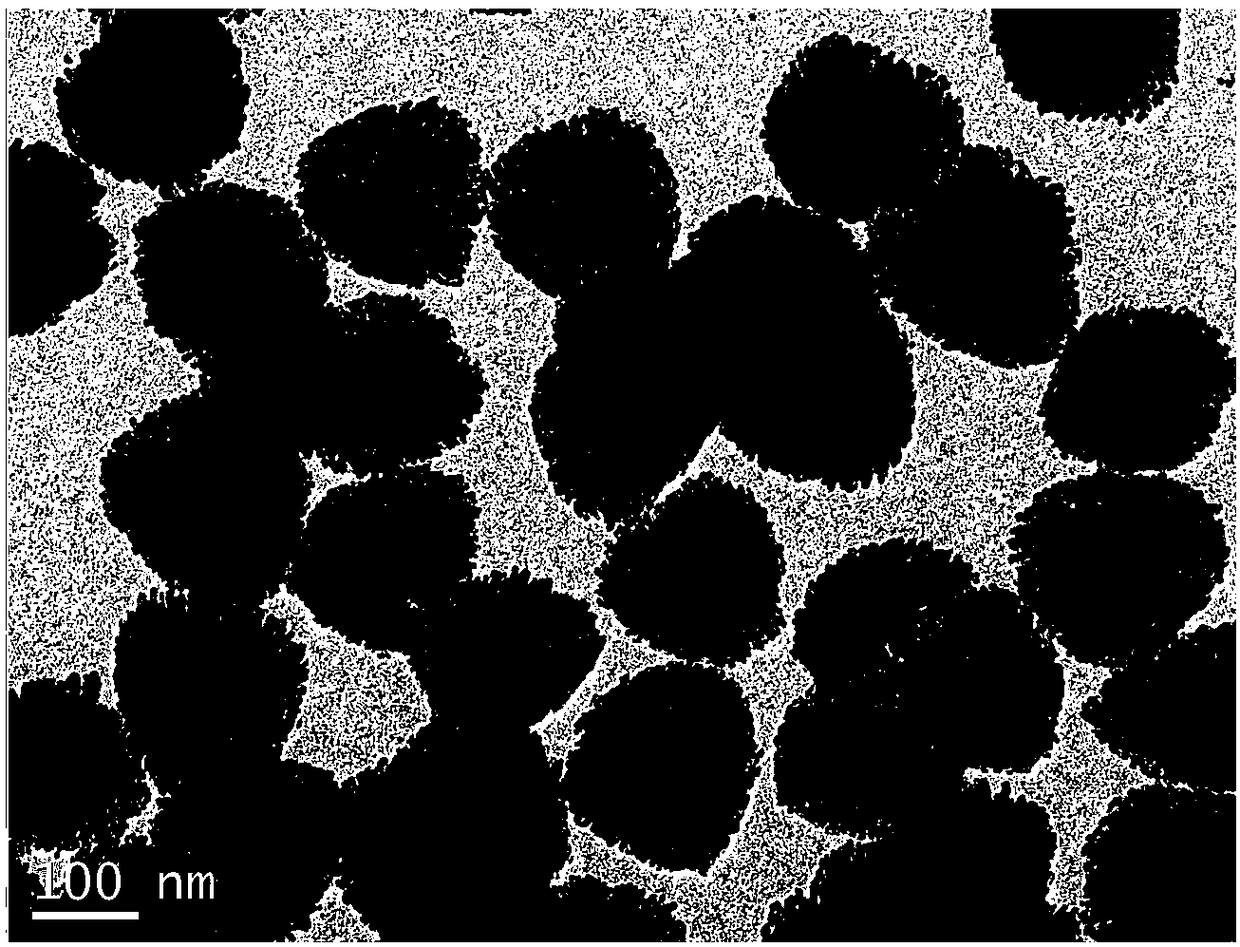

[0030] The TEM image of the ZnO nano powder obtained in this example is shown in Fig. 1(a), and the SEM image is shown in Fig. 1(b). It can be seen from Figure 1(a) and (b) that the ZnO nanopowder obtained by the preparation method of this application ha...

Example Embodiment

[0031] Example 2

[0032] A preparation method of porous conical ZnO nano powder includes the following steps:

[0033] (1) Dissolve 0.77062 g of anhydrous zinc acetate in 100 mL of mixed solvent to obtain a zinc acetate solution;

[0034] Among them, the mixed solvent is composed of absolute ethanol, ethylene glycol and deionized water in a volume ratio of 50:50:1;

[0035] (2) The zinc acetate solution obtained in step (1) is heated to 50° C. under magnetic stirring and kept for 40 minutes to obtain a solid-liquid mixture containing ZnO precipitation;

[0036] (3) The solid-liquid mixture containing the ZnO precipitate obtained in step (2) is centrifuged and washed 5 times with absolute ethanol, and then the centrifuged-washed product is dried at 80° C. for 10 hours to obtain porous conical ZnO nanopowder.

Example Embodiment

[0037] Example 3

[0038] A preparation method of porous conical ZnO nano powder includes the following steps:

[0039] (1) Dissolve 0.5798 g of anhydrous zinc acetate in a mixed solvent consisting of 40 mL of methanol and 0.5 mL of deionized water to obtain a zinc acetate solution;

[0040] (2) The zinc acetate solution obtained in step (1) is heated to 75° C. under magnetic stirring and kept for 30 minutes to obtain a solid-liquid mixture containing ZnO precipitation;

[0041] (3) The solid-liquid mixture containing ZnO precipitate obtained in step (2) is centrifuged and washed 4 times with absolute ethanol, and then the centrifuged-washed product is dried at 60° C. for 6 hours to obtain porous conical ZnO nano powder.

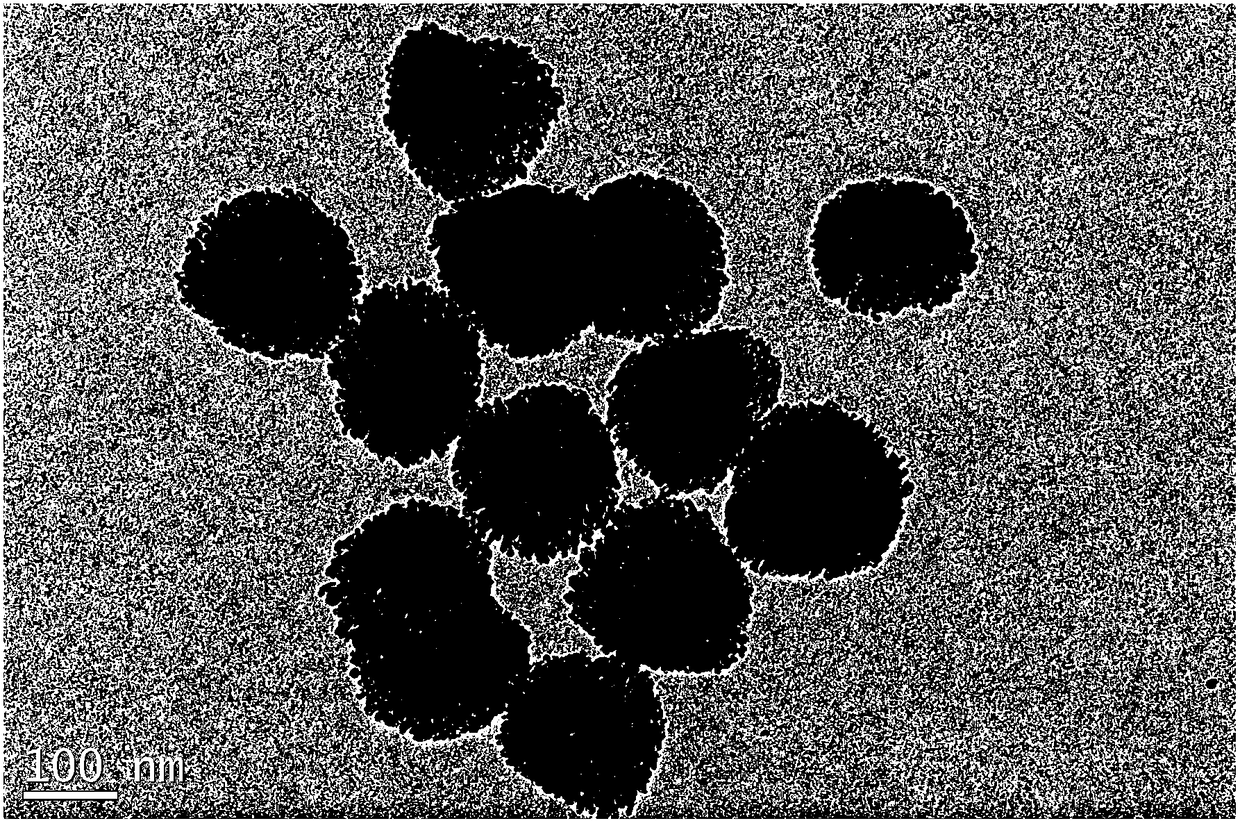

[0042] The SEM picture of the ZnO nano powder obtained in this example is shown in figure 2 . From figure 2 It can be seen that the ZnO nano powder obtained by the preparation method of the present application has a conical shape and a good porous structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap