A kind of cable material and preparation method thereof for new energy vehicle charging pile cable sheath

A technology for new energy vehicles and cable sheaths, applied in circuits, electrical components, plastic/resin/wax insulators, etc., can solve the problems of flame retardancy, environmental protection, high performance, low smoke, long-term and short-term thermal stability, etc. , to achieve the effect of environmental protection and no pollution in the production process, and the preparation method is simple and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] In any embodiment, the preparation method at least includes the following steps:

[0039] Step 1, taking each component according to the above-mentioned raw material ratio;

[0040] Step 2. According to the formula of functional auxiliary agent A and functional auxiliary agent B, premix respectively;

[0041] Step 3. Add PVC resin, functional additive B, plasticizer A, plasticizer B, and plasticizer C into the first reactor and stir at 100°C-130°C for 5-7min, then place in the second Lower the temperature in the reactor to 40-50°C and stir, add functional additive A and filling additive, mix, and granulate.

[0042] Compared with the prior art, the preparation method provided by the present invention is simple and easy to operate, and can be applied to mass production in factories. During normal production and use, ordinary polyolefin or PVC processing and production equipment can be used for processing and production, and the production process is environmentally frie...

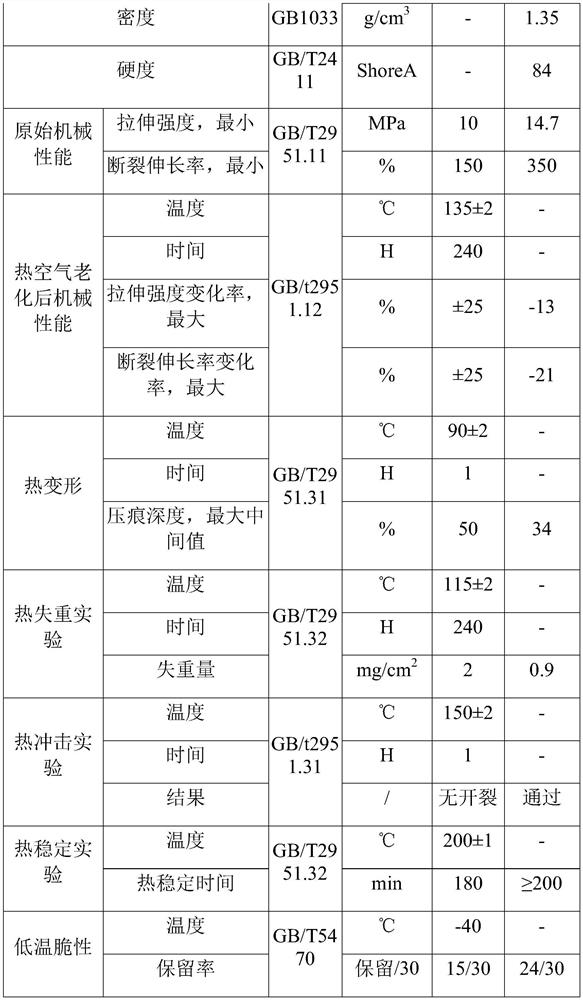

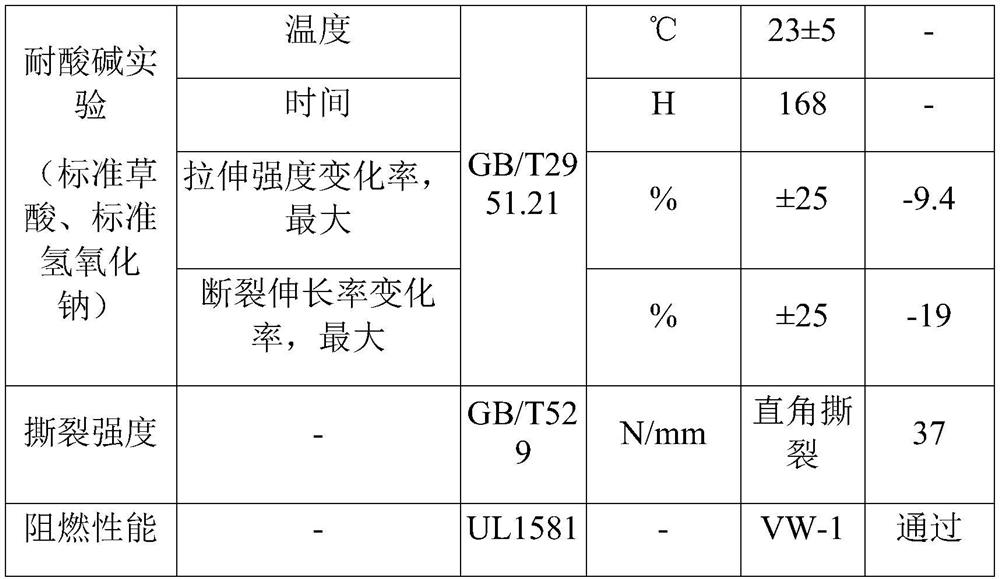

Embodiment 1

[0047] The embodiment of the present invention provides a cable material used for the cable sheath of a new energy vehicle charging pile. The material includes the following components in parts by weight: PVC resin: 100 parts, plasticizer A: 30 parts, Plasticizer B: 10 parts, Plasticizer C: 5 parts, Functional Auxiliary A: 47 parts, Functional Auxiliary B: 8 parts, Filling Auxiliary: 20 parts.

[0048] Wherein, the functional auxiliary agent A includes the following components in parts by weight: flame retardant A: 8 parts, flame retardant B: 4 parts, elastomer resin A: 12 parts, elastomer resin B: 20 parts Parts, branched polymer: 5 parts. The functional aid B, in parts by weight, includes the following components: heat stabilizer: 6 parts, metal soap stabilizer: 1 part, antioxidant: 0.4 part, ultraviolet absorber: 0.3 part, lubricant : 0.3 parts.

[0049] The above-mentioned preparation method of the cable material used for the cable sheath of the new energy vehicle char...

PUM

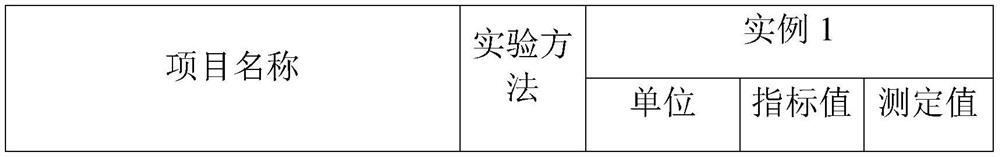

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com