Fabric capable of achieving ultraviolet protection

An anti-ultraviolet and ultraviolet technology, applied in the field of textiles, can solve problems such as uneven dispersion, complicated process steps, and strong toxicity, and achieve the effects of reduced demand, good wearing experience, and high softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

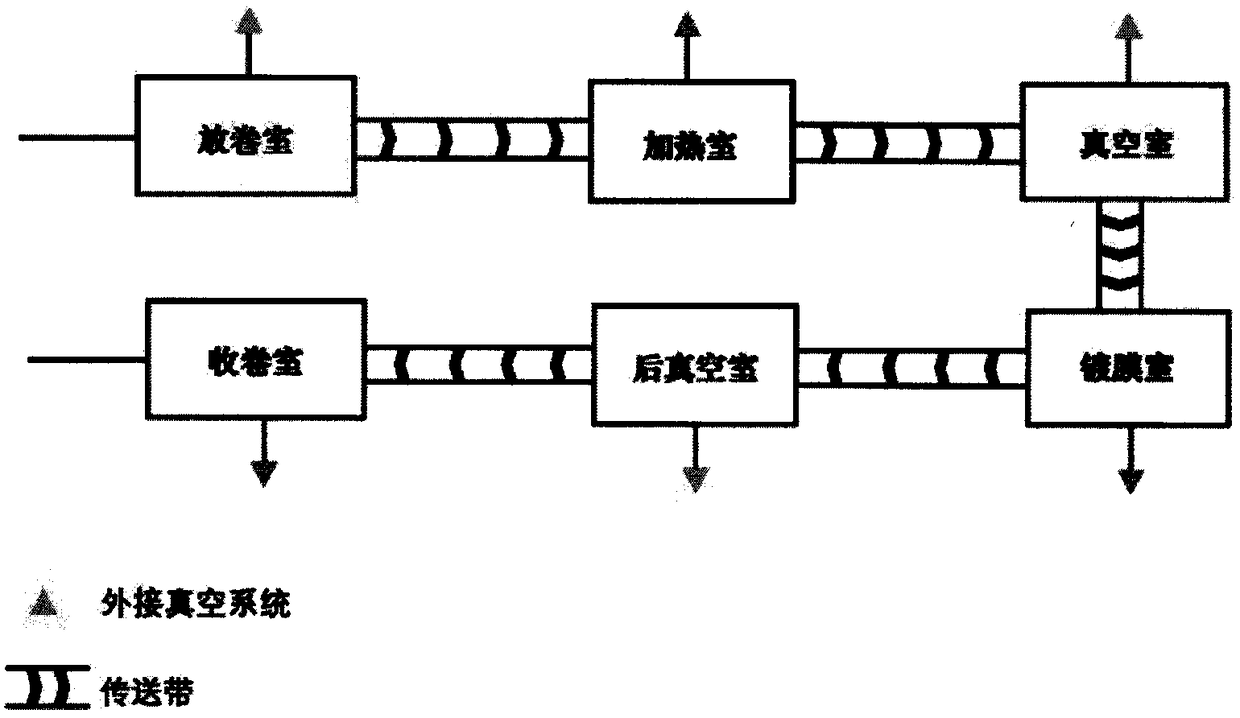

[0033] Such as figure 1 Shown, a kind of preparation method that can realize the fabric of anti-ultraviolet, it comprises:

[0034] The base fabric is cotton, and the base fabric is pre-treated to remove surface stains;

[0035] The base cloth is rolled into the unwinding chamber, and the vacuum degree of the unwinding chamber is kept at 1-1.5E -1 Pa interval;

[0036] The base cloth enters the heating chamber, so that the temperature of the base cloth rises to 75°C, and the vacuum degree of the heating chamber is kept at 1-1.5E -1 Pa;

[0037] The base cloth enters the pre-vacuum chamber, and the vacuum degree in the chamber is kept at 5E -2 Pa;

[0038] When the vacuum degree of the coating chamber reaches 1E -3 When the Pa is above, the base cloth enters the coating chamber, and the vacuum deposition method is used to form an ultraviolet reflection layer on the base cloth, and the target material is TiO 2 Target, magnetron sputtering power is 1800W;

[0039] The bas...

Embodiment 2

[0043] Such as figure 1 Shown, a kind of preparation method that can realize the fabric of anti-ultraviolet, it comprises:

[0044] The base fabric is cotton, and the base fabric is pre-treated to remove surface stains;

[0045] The base cloth is rolled into the unwinding chamber, and the vacuum degree of the unwinding chamber is kept at 2E -1 Pa interval;

[0046] The base cloth enters the heating chamber, so that the temperature of the base cloth rises to 58°C, and the vacuum degree of the heating chamber is kept at 2E -1 Pa interval

[0047] The base cloth enters the pre-vacuum chamber, and the vacuum degree in the chamber is kept at 3E -2 Pa interval;

[0048] When the vacuum degree of the coating chamber reaches 1E -3 When the Pa is above, the base cloth enters the coating chamber, and the ultraviolet reflection layer is formed on the base cloth by vacuum deposition method. The target materials are Ti and Ag respectively, and the sputtering power is 2500W and 3000W ...

Embodiment 3

[0053] Such as figure 1 Shown, a kind of preparation method that can realize the fabric of anti-ultraviolet, it comprises:

[0054] The base fabric is polyester, and the base fabric is pre-treated to remove surface stains;

[0055] The base cloth is rolled into the unwinding chamber, and the vacuum degree of the unwinding chamber is kept at 0.7E -1 Pa interval;

[0056] The base cloth enters the heating chamber, so that the temperature of the base cloth rises to 89°C, and the vacuum degree of the heating chamber is kept at 0.7E -1 Pa interval

[0057] The base cloth enters the pre-vacuum chamber, and the vacuum degree in the chamber is kept at 8E -2 Pa interval;

[0058] When the vacuum degree of the coating chamber reaches 1E -3 When Pa is above, the base cloth enters the coating chamber, and the ultraviolet reflection layer is formed on the base cloth by vacuum deposition method. The target materials are Zn, TiN, Ag, respectively, and the magnetron sputtering power is ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap