Closestool

A technology for toilets and toilets, which is applied to flushing equipment with water tanks, indoor sanitary plumbing installations, flushing toilets, etc. It can solve the problems such as low water pressure of toilets without tanks and cannot complete flushing, and achieve constant flushing water volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

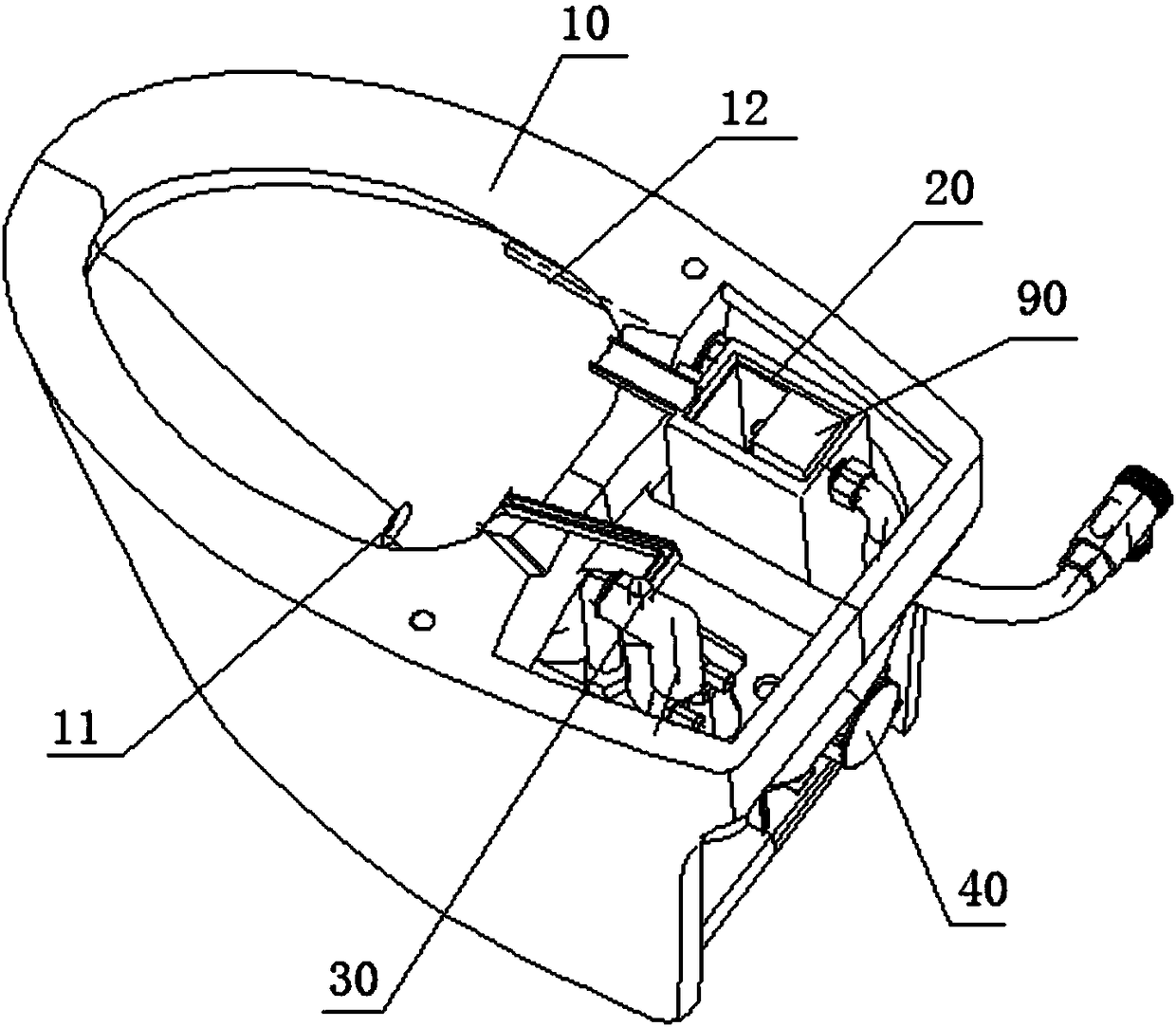

[0036] see figure 1 , the first embodiment provides a toilet, including a toilet body 10 , a water tank 20 , an air isolation device 30 and a water pump 40 .

[0037] Wherein, the toilet body 10 is provided with a spray port 11 facing the sewage outlet; The injection port 11 on the top is communicated with through the air isolation device 30, and the air isolation device 30 is used to prevent sewage from flowing backward from the injection port 11 of the toilet body to the water tank 20.

[0038] Analyzing the specific connection mode and positional relationship of the above-mentioned structure, it can be seen that: because the water pump 40 can extract the water in the water tank 20 and make the water spray out from the injection port 11 at a certain flow rate, no matter whether the water level in the water tank 20 is higher than the injection Port 11 can realize flushing of the toilet, that is, the position of the water tank 20 can be arbitrarily set according to needs, and...

Embodiment 2

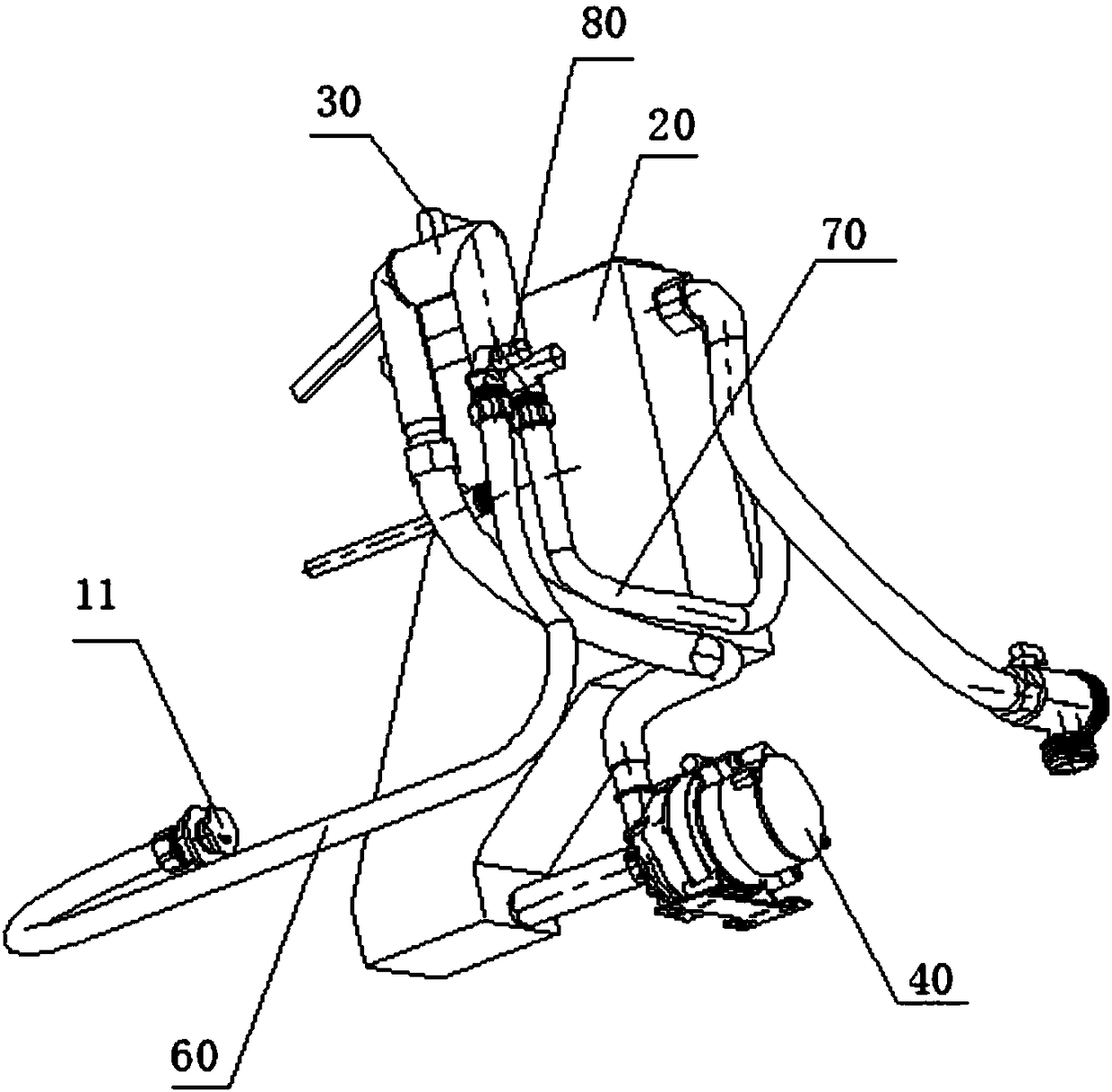

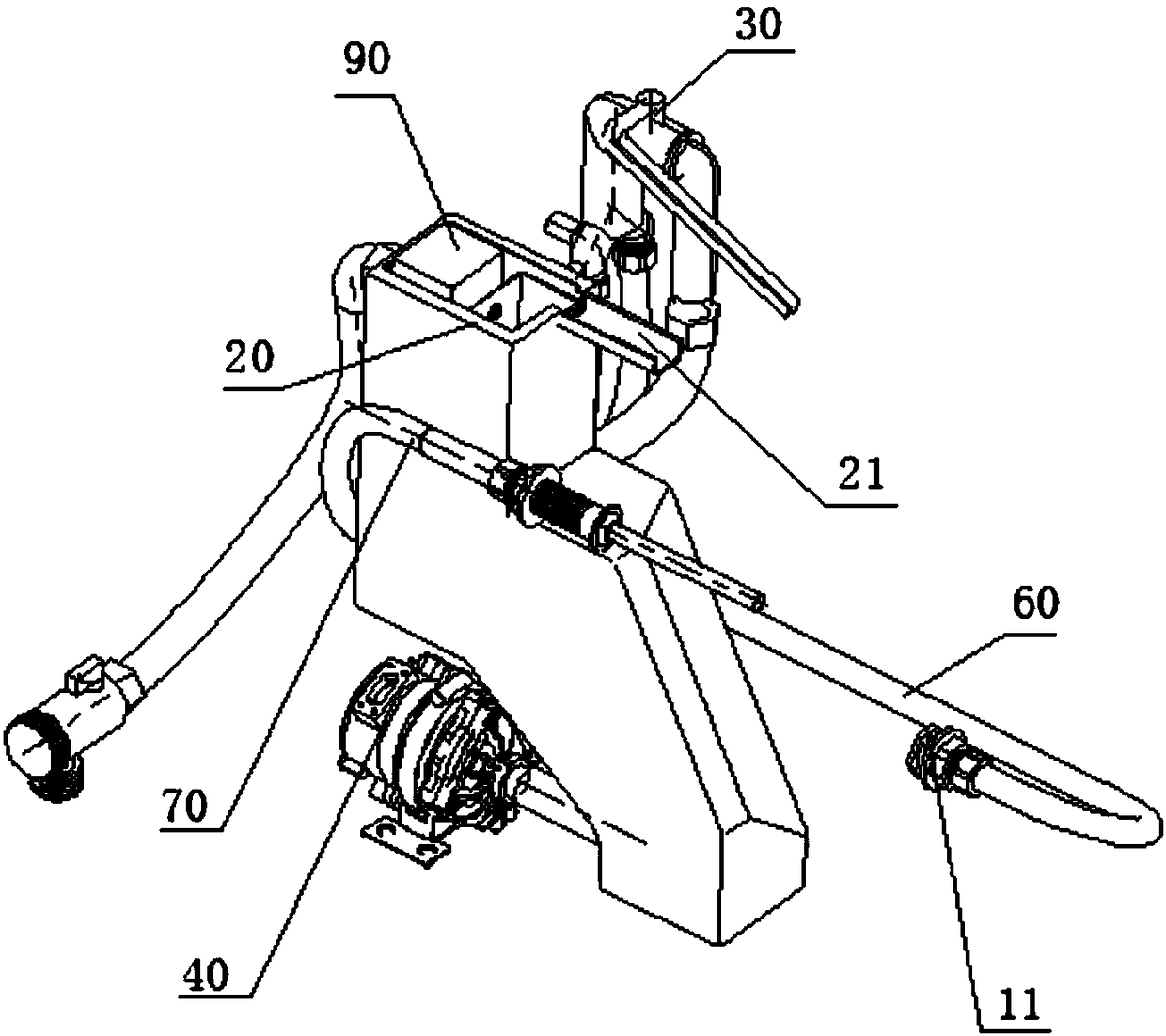

[0042] see figure 1 , the second embodiment provides a toilet, and also adopts the technical structural relationship of the toilet in the first embodiment; for example, the second embodiment provides a toilet, including a toilet body 10, a water tank 20 , an air isolation device 30 and a water pump 40; wherein, the toilet body 10 is provided with a spray port 11 facing the sewage outlet; the water pump 40 is used to extract the water in the water tank 20, and the water pump 40 The water outlet communicates with the injection port 11 on the toilet body 10 through the air isolation device 30 , and the air isolation device 30 is used to prevent sewage from flowing backward from the injection port 11 of the toilet body to the water tank 20 .

[0043] The toilet provided in the second embodiment has the same main structure as the toilet in the first embodiment; however, the toilet provided in the second embodiment also involves a specific structural design. The difference between th...

Embodiment approach

[0046] In the first possible implementation mode, a drain port can be set in the water tank, and the drain port on the water tank can be connected with the water inlet of the water pump; the existing toilet has a fixed seal between the drain assembly and the bottom of the water tank, so every time There will be about 10-20mm of water remaining at the bottom of the flushing water tank, and the water in the water tank cannot be fully utilized, resulting in a large waste of the volume of the water tank; The problem of volume waste of the water tank 20 is effectively solved.

[0047] In the second possible implementation mode, the water pump can be put into the water tank, and the water can be drawn directly from the water tank and delivered to the jet port of the toilet body.

[0048] In the specific structure, there are at least two possible implementation methods for the position of the distribution valve as follows:

[0049] For the first possible implementation, see figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com