Single-layer toughened glass partition wall

A technology of tempered glass and single-layer steel, which is applied to walls, building components, buildings, etc., can solve the problems of long curing time of glass glue, unreliable glass positioning, and difficult construction, and achieve novel and ingenious structure and reduce construction The effect of working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

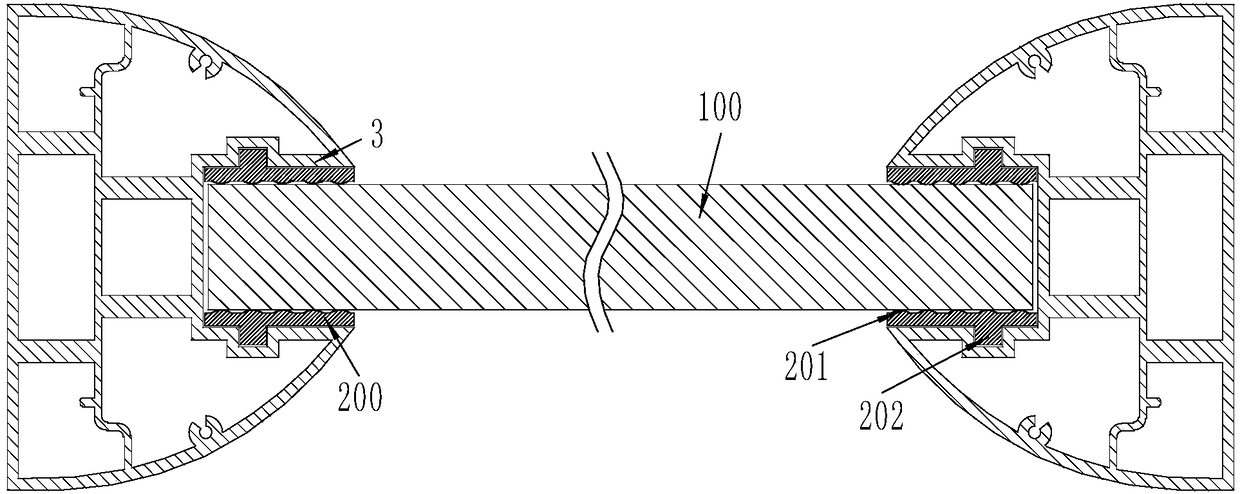

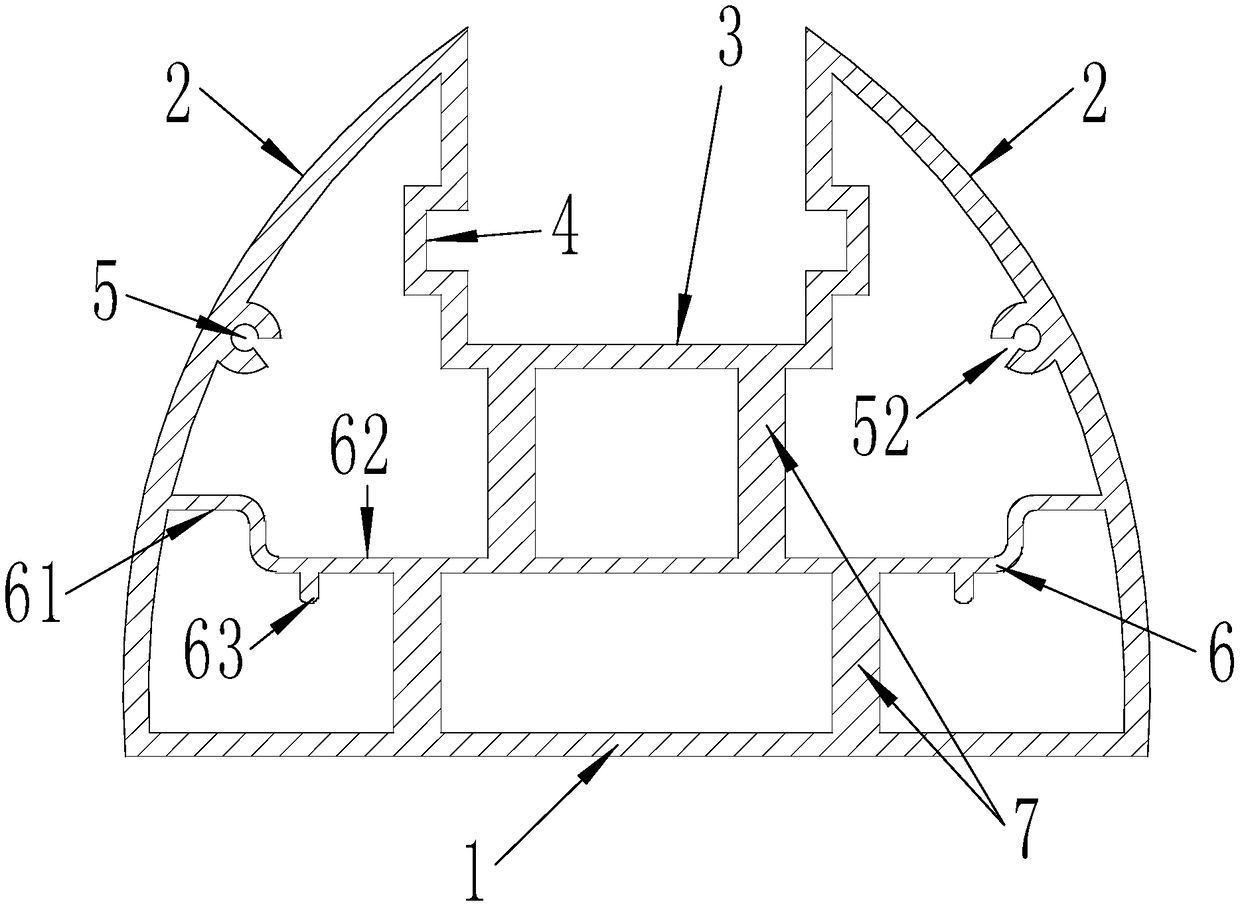

[0016] Such as Figure 1 ~ Figure 2 As shown, a single-layer tempered glass partition wall includes a tempered glass 100 and two opposite profiles, and the two ends of the tempered glass 100 are respectively embedded into corresponding profiles through the limiting parts 200; Extending to the sheet-shaped bottom edge 1, two opposite arc-shaped side walls 2 extending in the axial direction are provided at both ends of the sheet-shaped bottom edge 1, and there is an arc extending in the axial direction between the two arc-shaped side walls 2. An installation groove 3, the installation groove 3 is located on the side away from the sheet-shaped bottom edge 1, and two opposite positioning grooves 4 extending in the axial direction are provided on the groove walls on both sides of the installation groove 3, A cylindrical mounting rib 5 extending axially is respect...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap