Prefabricated combined construction column for brickwork structure and construction method using the same

A technology of masonry structure and construction method, applied in the direction of columns, piers, pillars, etc., can solve the problems of weak support, influence on the quality of structural columns, and poor pouring and vibration, and achieves low requirements for professional knowledge and shortens the The effect of construction period and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

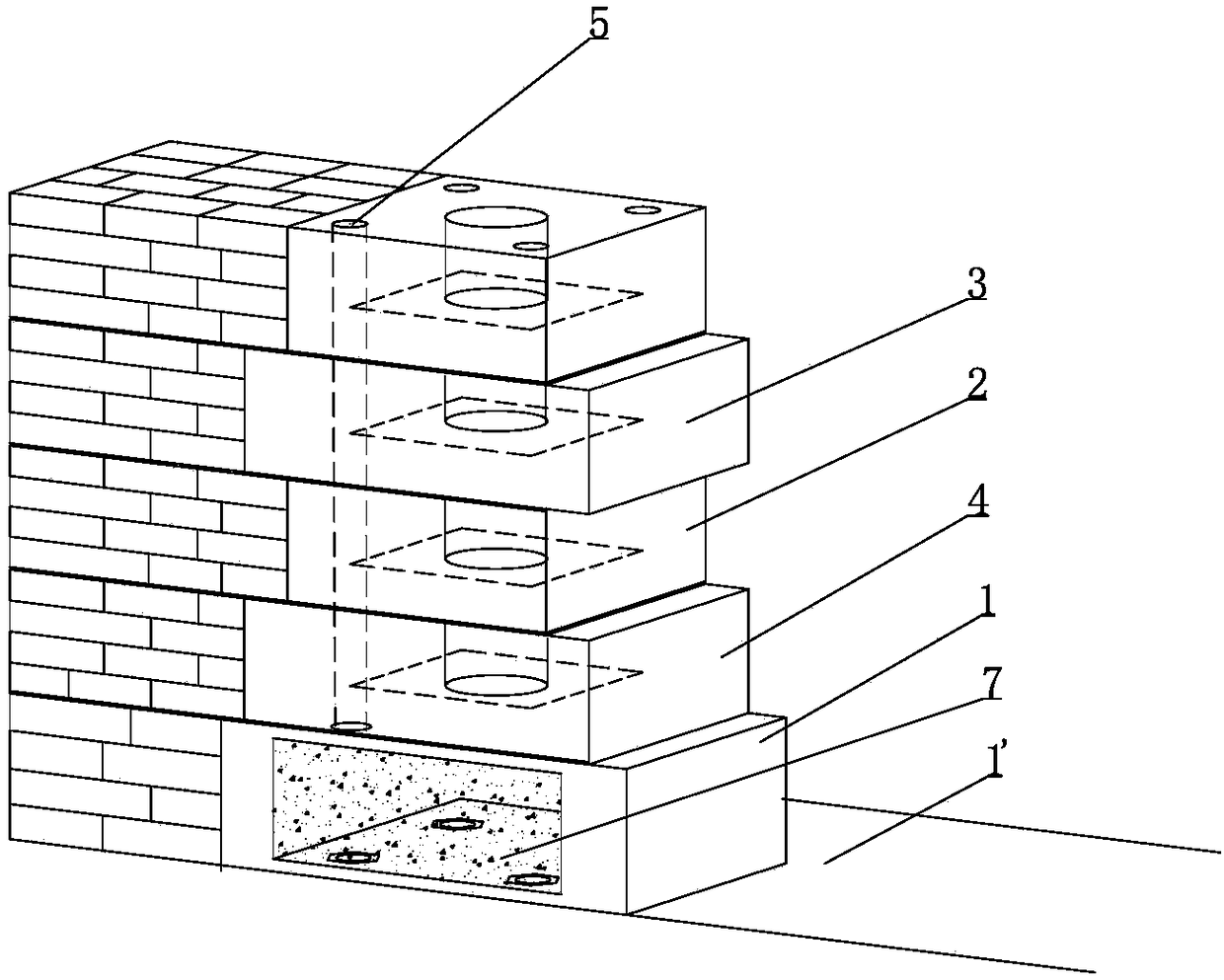

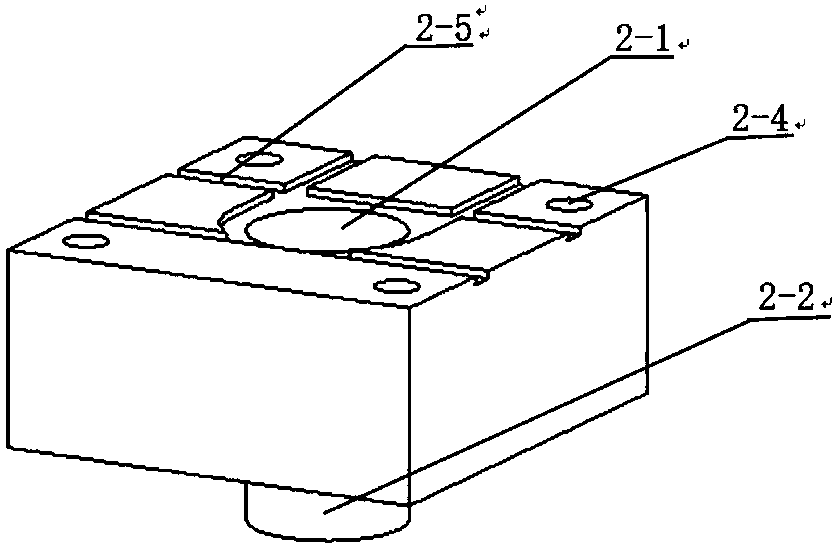

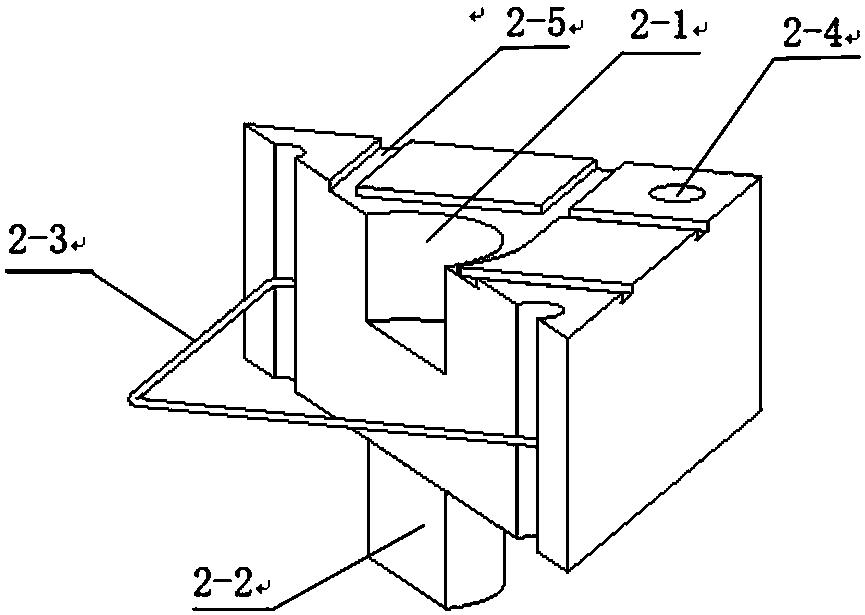

[0039] See Figure 1-10 , a prefabricated combined construction column for masonry structures, its innovative points are:

[0040] The prefabricated combined structural column consists of a steel connecting seat 1, a third precast concrete section 4 placed above the steel connecting seat, a plurality of first prefabricated concrete sections placed above the third precast concrete section and arranged alternately from bottom to top. The concrete section 2 and a plurality of second prefabricated concrete sections 3 are vertically connected to form.

[0041] The main body of the three precast concrete sections is a square block structure of equal width and height, the second precast concrete section and the third precast concrete section have t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com