Dynamic monitoring device and monitoring method for danger to industrial equipment

A technology for dynamic monitoring and industrial equipment, applied in the direction of measuring devices, furnace safety devices, lighting and heating equipment, etc., can solve the problems of occupying operating space, hidden safety hazards of operators, cumbersome and other problems, and achieve small operating space occupation and monitoring methods. The effect of simplicity and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

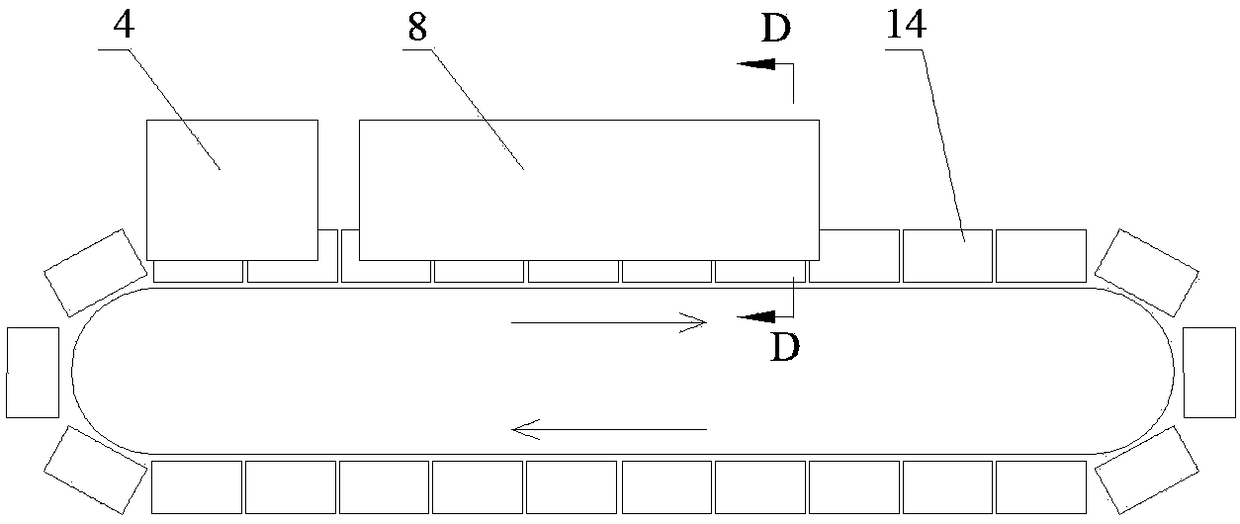

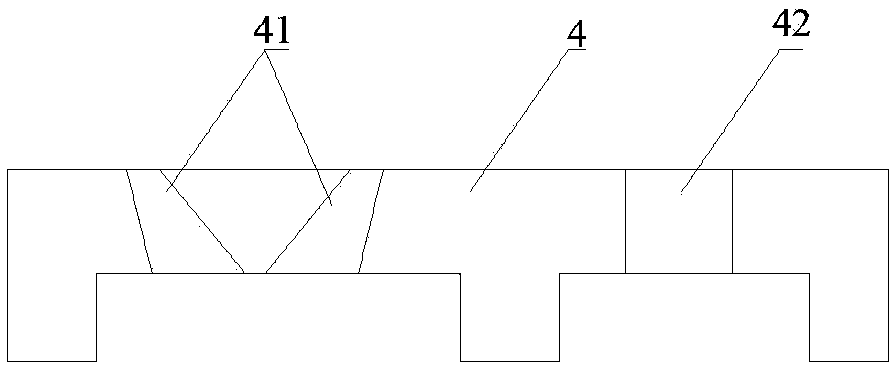

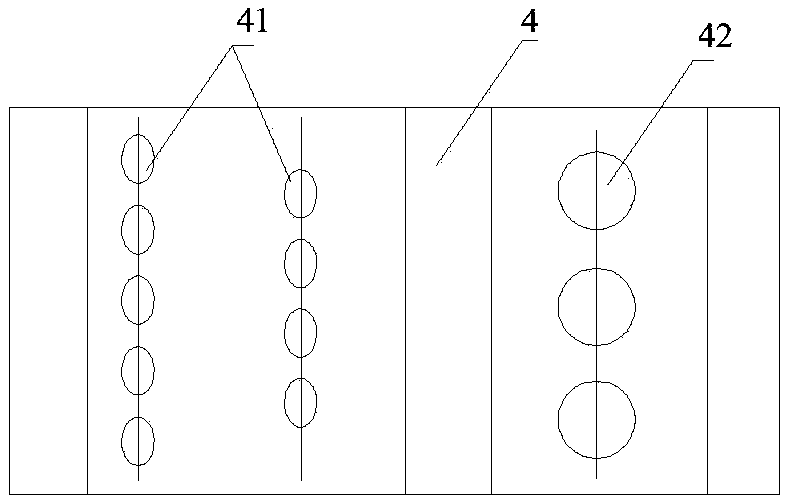

[0069] Such as Figure 1-3 , Image 6 As shown, the dynamic monitoring device for CO leakage of sintering equipment in this embodiment, the sintering equipment includes an ignition furnace 4, a gas injection device 8 and a sintering equipment trolley 14, and the ignition furnace 4 includes two rows of ignition burners 41 and a row of heat preservation burners. nozzle 42 , the gas injection device 8 includes a gas injection cover 81 and a gas injection pipeline 82 . At least one set of dynamic monitoring device is provided. The dynamic monitoring device includes a patrol device 1, a CO detector 21 and a controller 3. The track 12 on the furnace top and / or the top of the gas injection cover 81, the CO detector 21 is installed on the patrol robot 11, and the patrol robot 11 runs on the track 12 under the drive of the driving device, and the CO detector 21 will be on the ignition furnace 4 The monitoring signals received by the furnace top and / or the top of the gas injection hoo...

Embodiment 2

[0086] like Figure 14 , Figure 15 As shown, the dynamic monitoring device for CO leakage of the rotary kiln 7 valve group platform 73 in this embodiment, the rotary kiln 7 includes a kiln body 71, a burner device for heating the kiln body 71 and a driving device for driving the kiln body 71 to rotate, the burner The device includes a central burner 72 and a valve group platform 73 for supplying fuel to the central burner 72 . The dynamic monitoring device includes a patrol device 1, a CO detector 21 and a controller 3. The patrol device 1 includes a patrol robot 11, a driving device (including a driving motor and a traveling wheel 26) and a track 12 arranged on the upper part of the valve group platform 73, and the CO detection The instrument 21 is installed on the patrol robot 11, and the patrol robot 11 runs on the track 12 driven by the driving device. The CO detector 21 transmits the monitoring signal received on the upper part of the valve group platform 73 to the cont...

Embodiment 3

[0102] like Figure 19 As shown, the dynamic monitoring device for CO leakage of the lime shaft kiln 9 in this embodiment, the lime shaft kiln 9 includes a shaft kiln body 91, a feeding device 92 and a blower device 93, and the feeding device 92 is arranged on the top of the shaft kiln body 91, The blower device 93 is arranged at the bottom of the shaft kiln body 91. The dynamic monitoring device includes a patrol device 1, a CO detector 21 and a controller 3. The patrol device 1 includes a patrol robot 11, a driving device (including a driving motor and traveling wheels 26) and The track 12 arranged around the shaft kiln body 91, the CO detector 21 is installed on the patrol robot 11, and the patrol robot 11 runs on the track 12 under the drive of the driving device, and the CO detector 21 will receive the CO detector around the shaft kiln body 91 The monitoring signal is transmitted to the controller 3 in real time.

[0103]In this embodiment, the patrol device 1 is a light...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com