Novel tubular conveyer belt rebound force measuring device and measuring method thereof

A technology for measuring devices and conveyor belts, applied in measuring devices, force/torque/work measuring instruments, instruments, etc., can solve the problems of inconvenient industrial field measurement, inaccurate measurement results, large occupied area, etc., and achieve simple technical means Ease of operation, high measurement accuracy and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

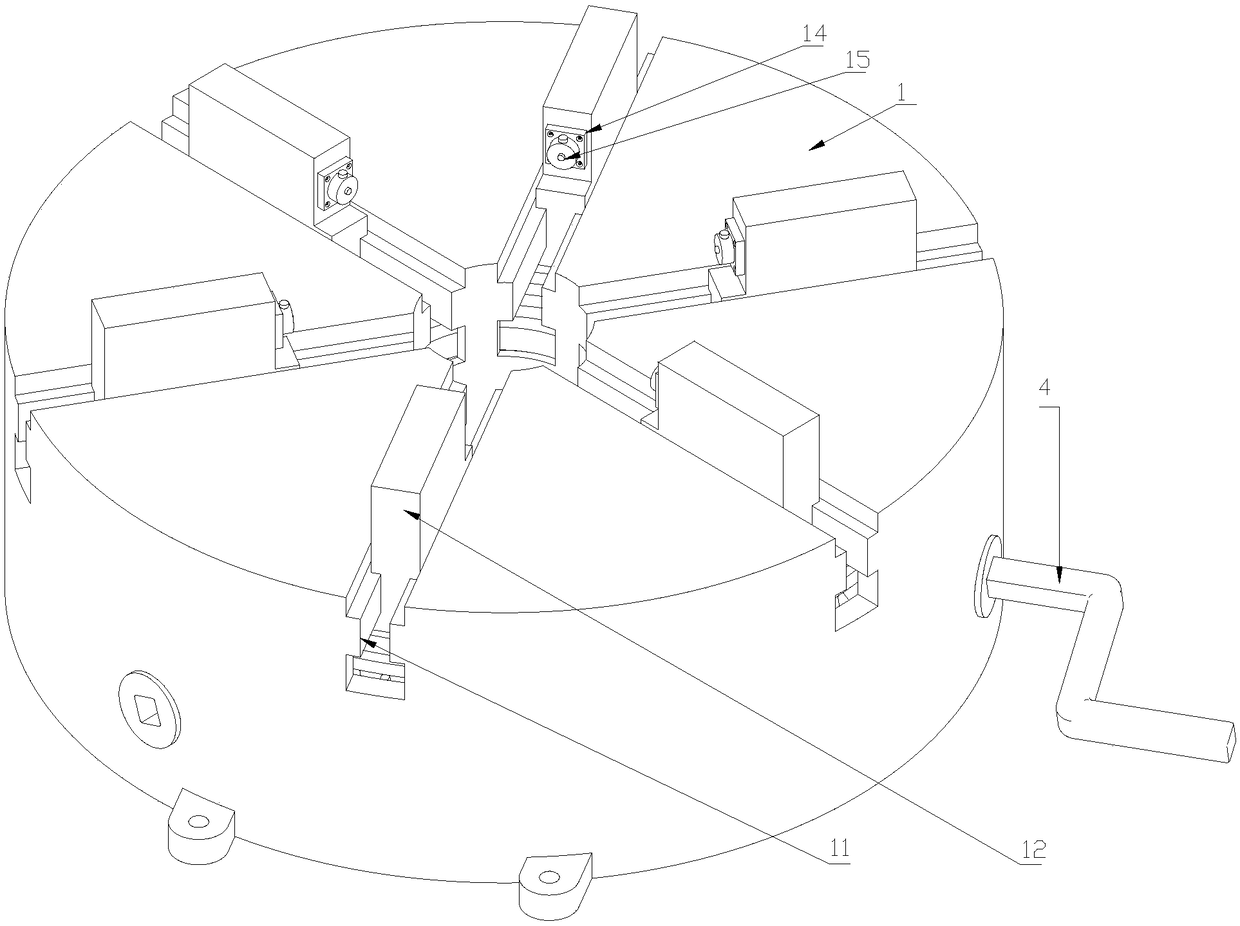

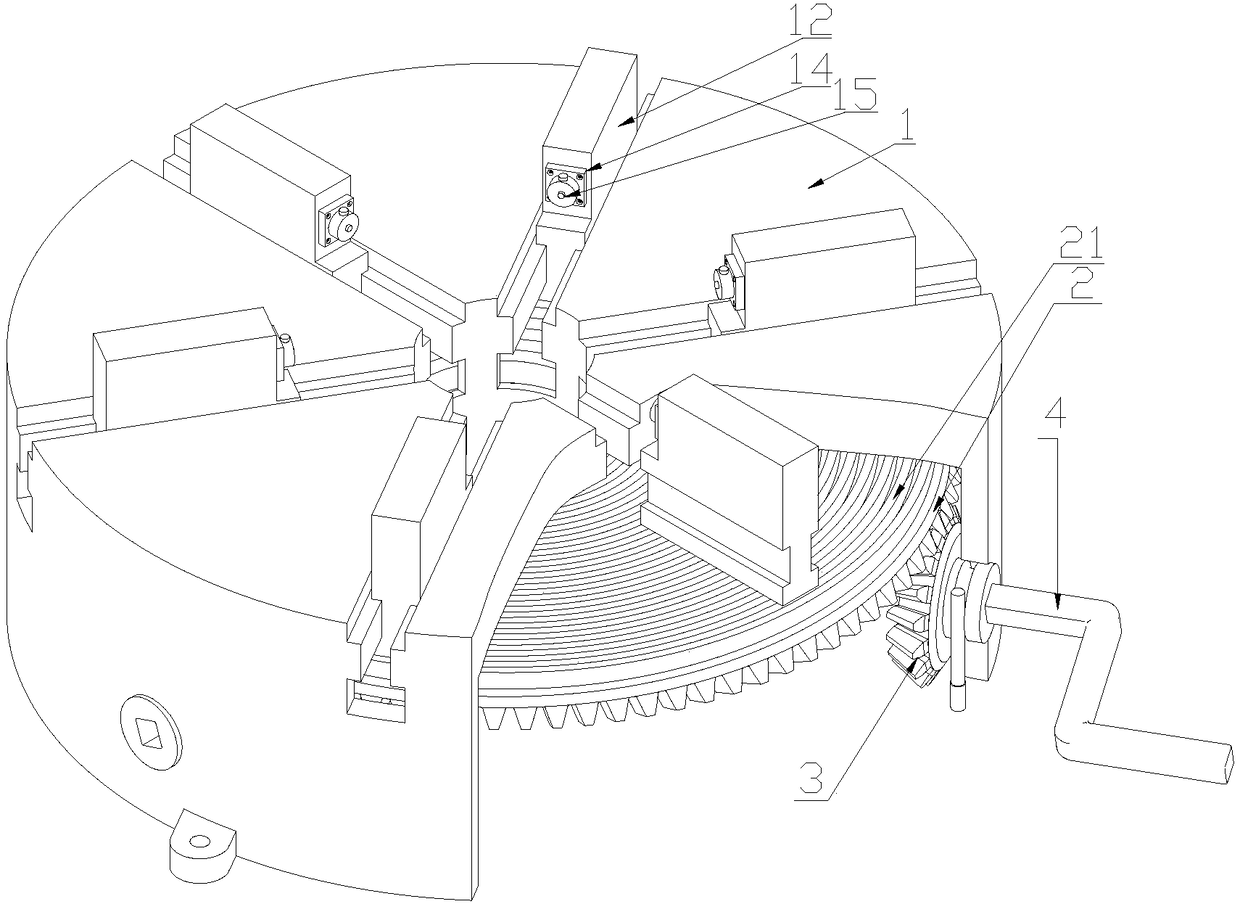

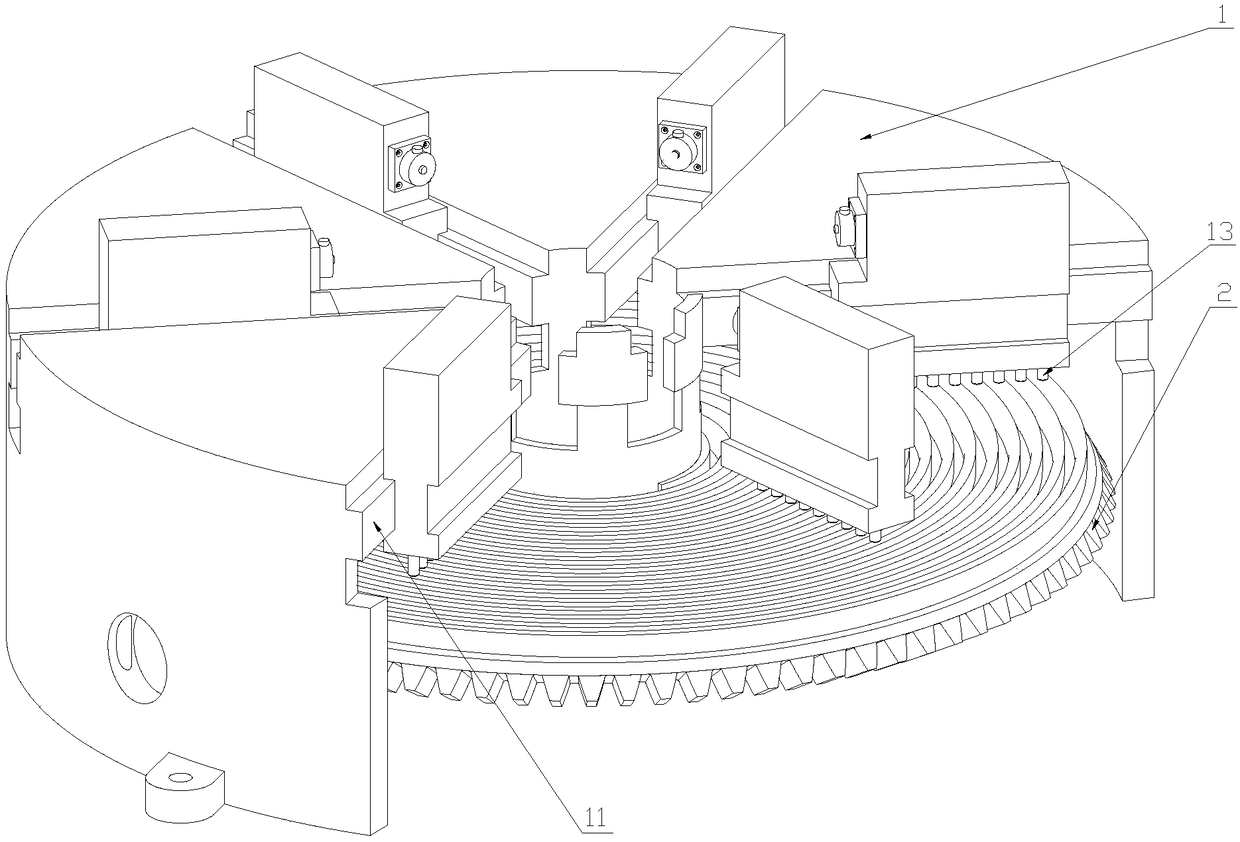

[0032] Such as Figure 1-6 Shown. The invention discloses a new type of tube-type conveyor belt rebound force measuring device, which comprises a chuck shell 1 and a bevel gear disk 2 coaxially installed in the chuck shell 1;

[0033] The upper end surface of the bevel gear plate 2 is provided with a plane thread groove 21;

[0034] A plurality of clamping grooves 11 with the same structure are symmetrically opened along the radial direction of the chuck housing 1, and each clamping groove 11 is provided with a clamping claw 12 with the same structure, and each clamping claw 12 is restricted in the clamping On the groove 11, it can slide in the groove 11; on the lower side of the clamping jaw 12, there are a plurality of pins 13 that mesh with the plane thread groove 21 at equal intervals; when the bevel gear plate 2 rotates, the clamping Pushed by the flat thread groove 21, the jaws 12 move synchronously at equal intervals along the track of the groove 11 toward the center or th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com