Double-sided OLED display and manufacturing method thereof

A production method and display technology, which are applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., can solve the problems of complex process, heavy structure and high production cost, and achieve the effect of wide application range and expansion of application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

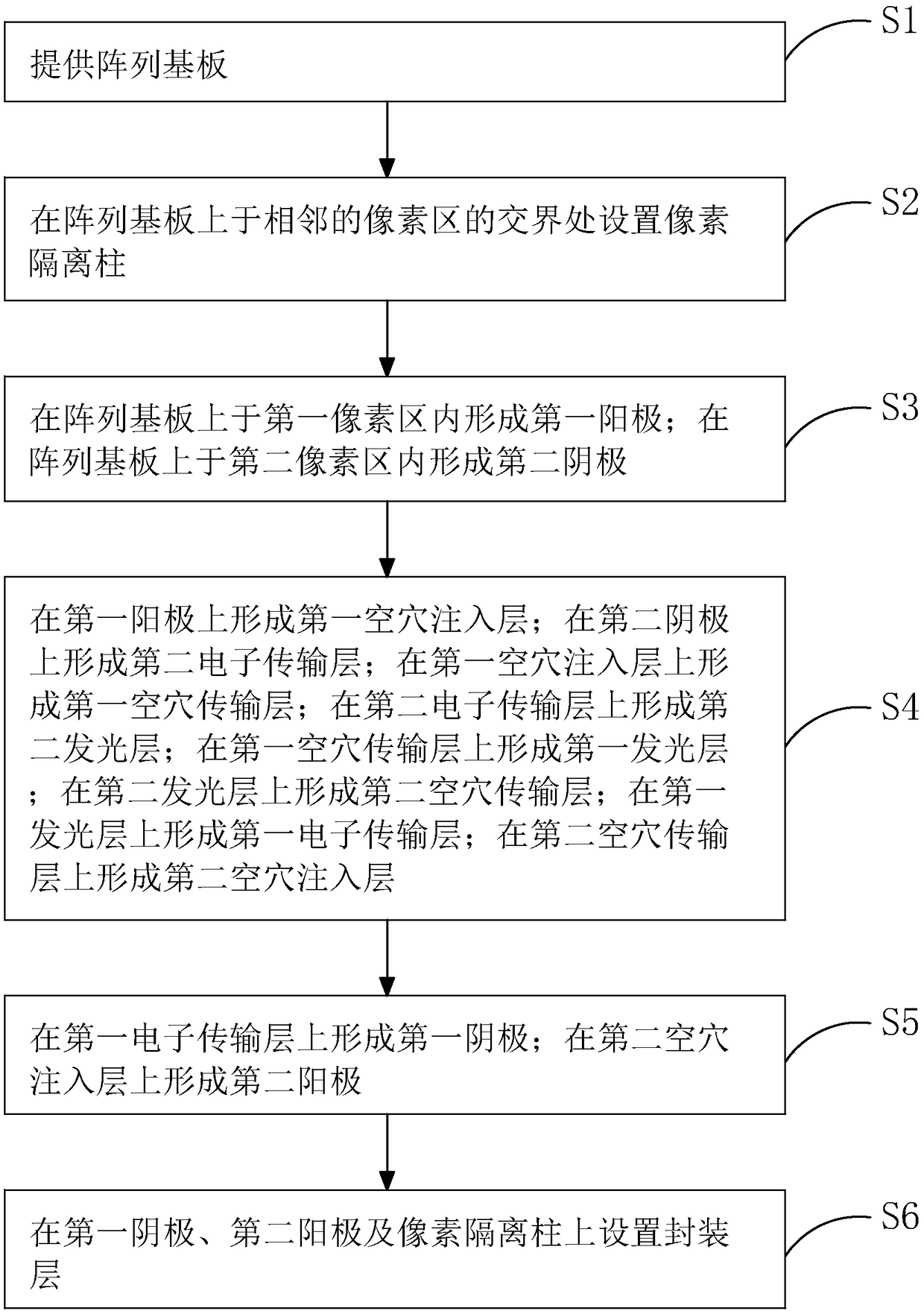

[0047] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

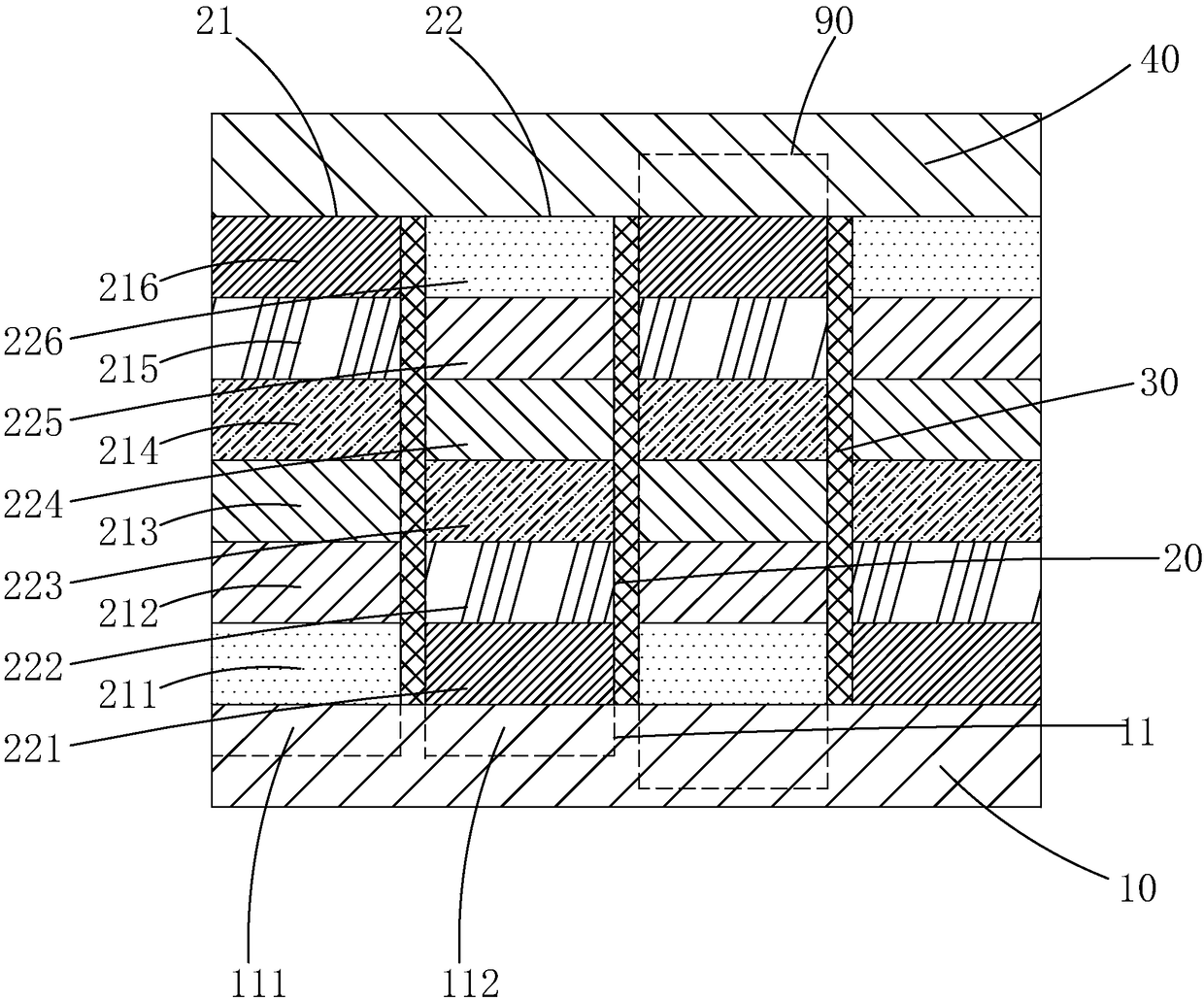

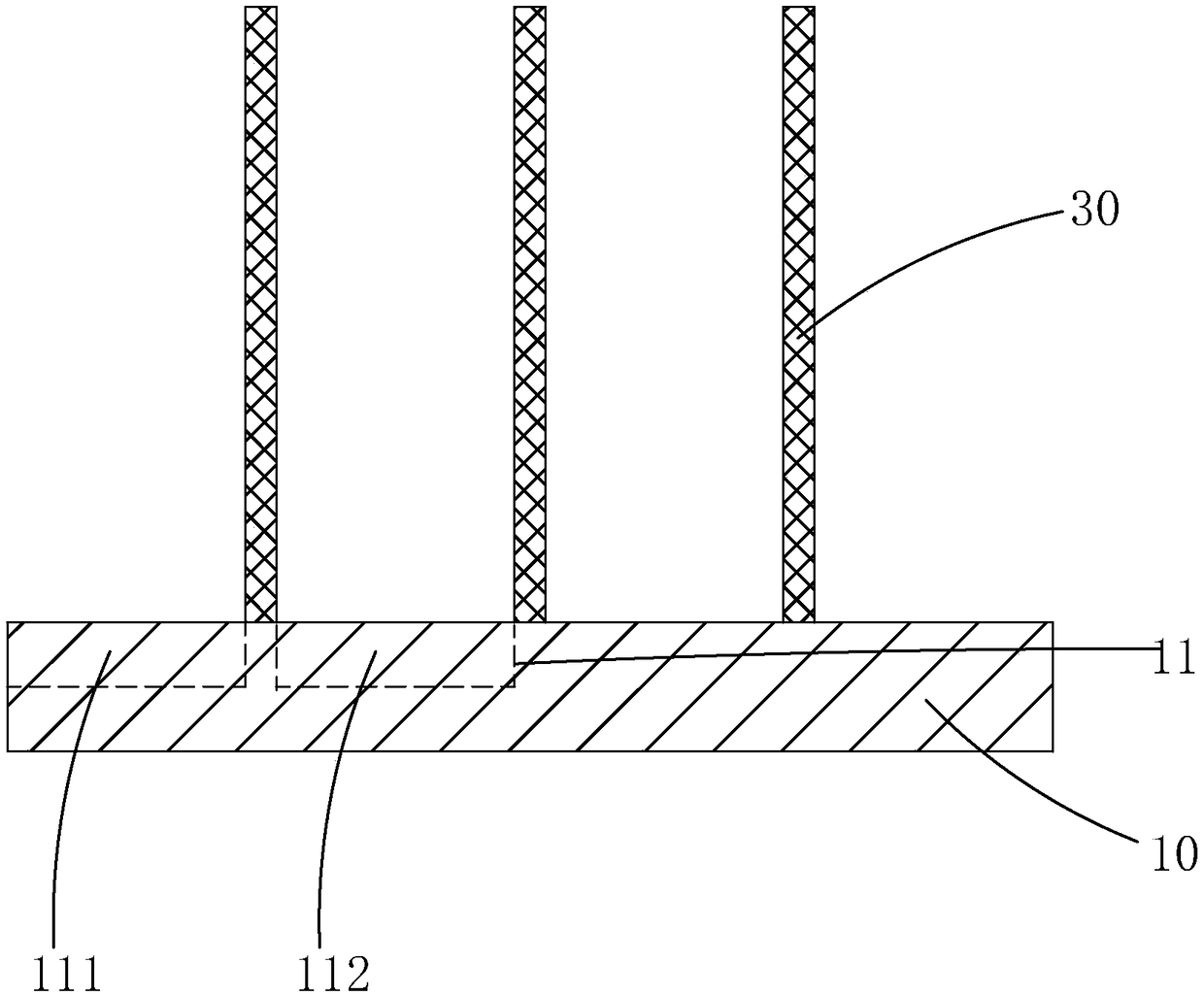

[0048] see figure 1 , the present invention provides a double-sided OLED display, comprising: an array substrate 10, a plurality of OLED devices 20 disposed on the array substrate 10, pixel isolation columns 30 disposed on the array substrate 10, and a plurality of OLED devices 20 and The encapsulation layer 40 on the pixel isolation posts 30 .

[0049] Wherein, the array substrate 10 is provided with a plurality of pixel regions 11 arranged in an array, and the plurality of pixel regions 11 include first pixel regions 111 and second pixel regions 112 arranged alternately in sequence; the pixel isolation The column 30 is set corresponding to the junction of adjacent pixel regions 11;

[0050] The plurality of OLED devices 20 include a first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com