A split type transmission line deicer

A technology for transmission lines and deicing machines, which is applied in the installation of electrical components and cables, overhead installations, etc., and can solve problems such as difficult deicing of transmission lines, unreliable walking of deicing machines, and poor cold resistance of deicing machines , to achieve the effect of improving working strength, simple structure and good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

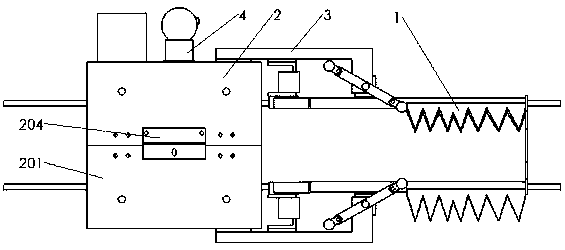

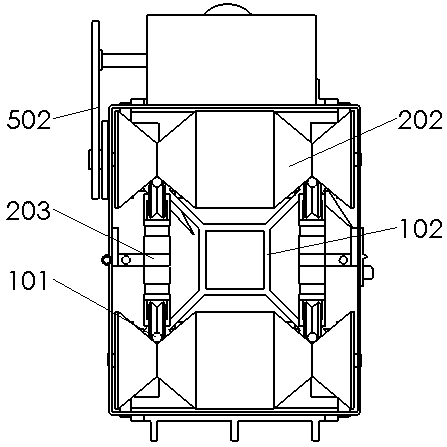

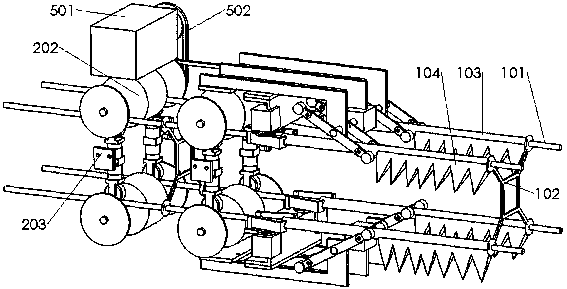

[0028] In conjunction with accompanying drawing, the embodiment that the present invention adopts is:

[0029] A split type transmission line deicer, comprising a main box 2, a deicing mechanism 3, a control and monitoring device 4 and a driving machine; the deicing mechanism 3 is installed on the upper and lower surfaces of the main box 2, and the The control and monitoring device 4 and the driving machine are installed on the upper surface of the main box body 2; the deicing mechanism 3 is divided into an ice-beating mechanism and an ice-cutting mechanism, and the ice-breaking mechanism includes an ice-beating rod 306, an ice-beating hammer 307 and an ice-breaking mechanism. Ice hitting motor 308, the ice hitting motor 308 is installed on the first bracket 301, the ice hitting motor 308 drives the rotation of the ice hitting rod 306 through the shaft to further drive the ice hammer 307 to remove ice, and the ice cutting mechanism is installed on the first bracket 301, the ic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com