A fast design method for rotor tooth width of bearingless flux switching motor

A technology of magnetic flux switching motor and design method, applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problem of blind selection of initial rotor tooth width, time-consuming increase of rotor tooth width, and published research results. and other problems, to achieve the effect of less calculation amount and calculation time, reducing the pulsation amplitude and increasing the output capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solution of the present invention will be specifically described below in conjunction with the accompanying drawings.

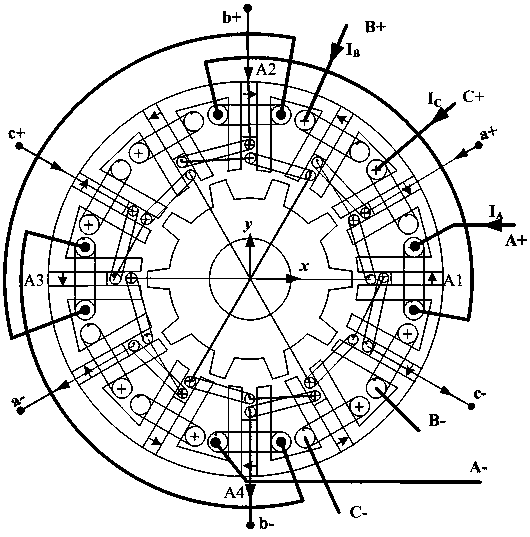

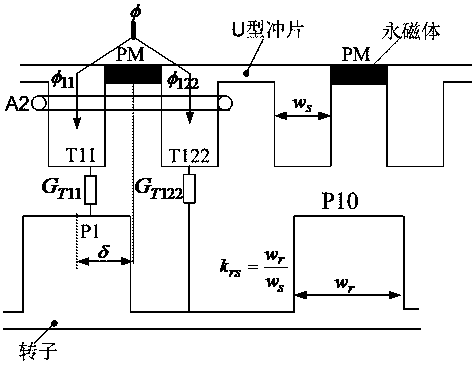

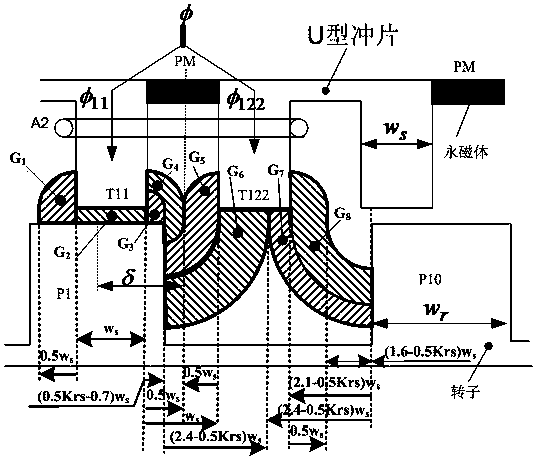

[0035] A method for quickly designing the rotor tooth width of a bearingless flux switching motor provided by the present invention provides a bearingless flux switching motor structure with three-phase suspension windings. Its basic structure is similar to that of a three-phase flux switching permanent magnet motor, and its stator is composed of It is composed of 12 U-shaped iron core punches, and a permanent magnet is sandwiched between two adjacent U-shaped iron core punches. The inner side of the stator is provided with suspension windings a, b, c; the implementation steps of this method are as follows,

[0036] Step S1. According to the design theory of flux switching motor or AC motor, the stator tooth width is determined, and the stator slot width is the same as the stator tooth width;

[0037] Step S2. Determine the air gap lengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com